Magnetic-clip trash bin

A technology of trash cans and magnetic blocks, applied in trash cans, garbage collection, household appliances, etc., can solve the problems of inconvenient sanitation and cleaning, increase work intensity, and direct garbage entry, etc., to achieve convenient and safe transportation, convenient and efficient disassembly, The effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

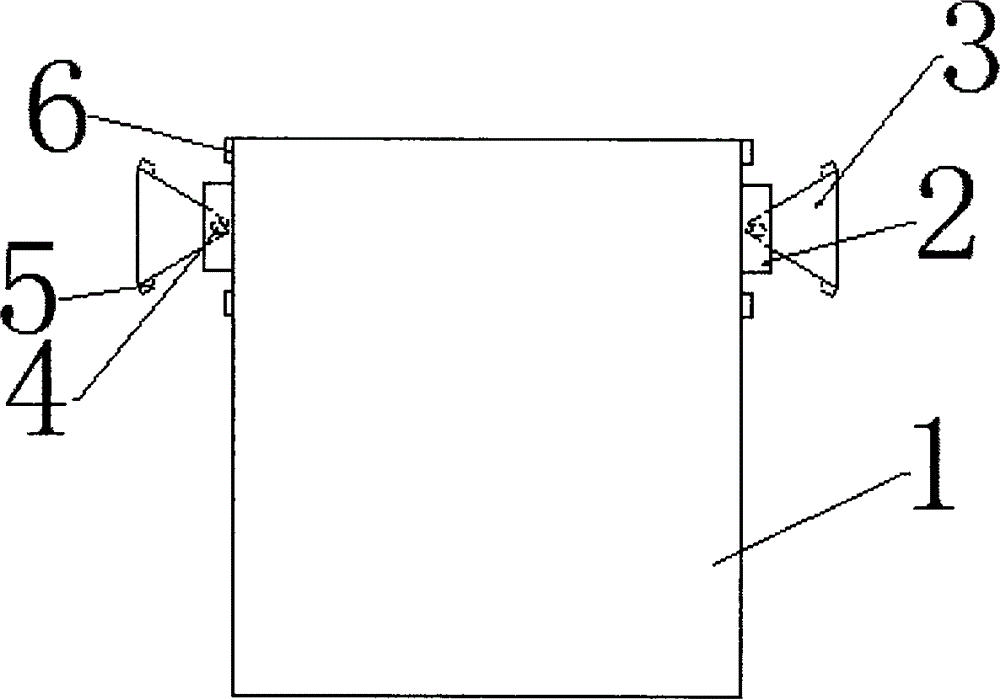

[0014] An embodiment of the magnetic clip trash can disclosed by the present invention includes a cylinder body 1 and the same number of magnetic clips and magnetic blocks 6, the cylinder body 1 is cylindrical or truncated, and the magnetic clip includes a "concave" type with a shaft hole. The seat 2, the rotating shaft 4 and the clip body 3 provided with the armature 5, the magnetic block 6 is arranged on the outer upper end of the cylinder body 1 and at least two magnetic blocks 6 of the same layer are evenly arranged at the same level along the cylinder body 1, and the seat 2 Correspondingly and vertically arranged below the magnetic block 6, the clip body 3 is a triangular prism and one end of the clip body 3 is provided with a fixing hole, the rotating shaft 4 passes through the fixing hole on the clip body 3 and the two ends of the rotating shaft 4 pass through the seat 2 The rotating shaft hole is connected to the seat 2, and an armature 5 is provided at the end of the c...

Embodiment 2

[0016] Such as figure 1 As shown, an embodiment of the magnetic clip trash can disclosed by the present invention includes a cylinder body 1 and the same number of magnetic clips and magnetic blocks 6. The cylinder body 1 is cylindrical or truncated cone, and the magnetic clip includes a " "Concave" type seat 2, rotating shaft 4 and clip body 3 provided with armature 5, magnetic block 6 is arranged on the outer upper end of cylinder body 1 and at least two magnetic blocks 6 of the same layer are evenly arranged along cylinder body 1 at the same level Correspondingly, the magnetic block 6 is provided with upper and lower layers on the outside of the cylinder body 1, and the upper and lower layers of the magnetic block 6 correspond to the position of the armature 5 on the clip body 3 when it is close to the cylinder body 1, and the seats 2 are vertically arranged correspondingly Below the magnetic block 6, the clip body 3 is triangular prism-shaped and one end of the clip body 3...

Embodiment 3

[0018] A structural schematic diagram of an embodiment of a magnetic clip garbage bin disclosed by the present invention, including a cylinder body 1 and the same number of magnetic clips, anti-slip sleeves and magnetic blocks 6, the cylinder body 1 is cylindrical or frustum-shaped, and the magnetic clip includes a rotating shaft. The "concave" type seat 2 of the hole, the rotating shaft 4 and the clamp body 3 provided with the armature 5, the magnetic block 6 is arranged on the upper end of the outer side of the cylinder body 1 and the same layer of magnetic blocks 6 is uniformly arranged at least at the same level along the cylinder body 1 There are two, the base 2 is arranged vertically below the magnetic block 6 respectively, the clip body 3 is a triangular prism and one end of the clip body 3 is provided with a fixing hole, the rotating shaft 4 passes through the fixing hole on the clip body 3 and the rotating shaft 4 The two ends are connected to the seat 2 through the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com