Method and device for preventing strip steel from deflecting

A strip deviation and strip steel technology, which is applied in transportation and packaging, electrolysis process, electrolysis components, etc., can solve problems such as strip deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

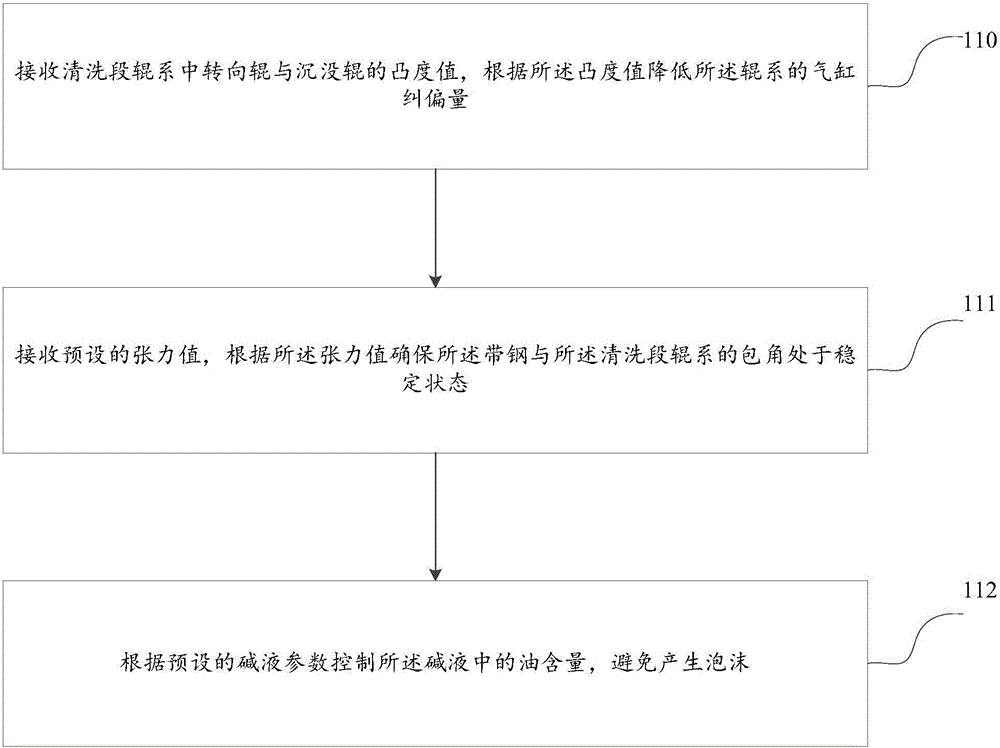

[0029] This embodiment provides a method for preventing strip deviation, such as figure 1 As shown, the method includes the following steps:

[0030] Step 110, receiving the convexity value of the steering roller and the sinking roller in the roller system of the cleaning section, and reducing the deviation correction amount of the cylinder of the roller system according to the convexity value.

[0031] In this step, in order to improve the self-correction ability of the roller system in the cleaning section, the deviation correction amount of the strip running at high speed in the cleaning section is reduced. According to the principle of roller effect, the convexity value of the steering roller and the sinking roller in the roller system in the cleaning section is received, and the deviation correction amount of the cylinder of the roller system is reduced according to the convexity value.

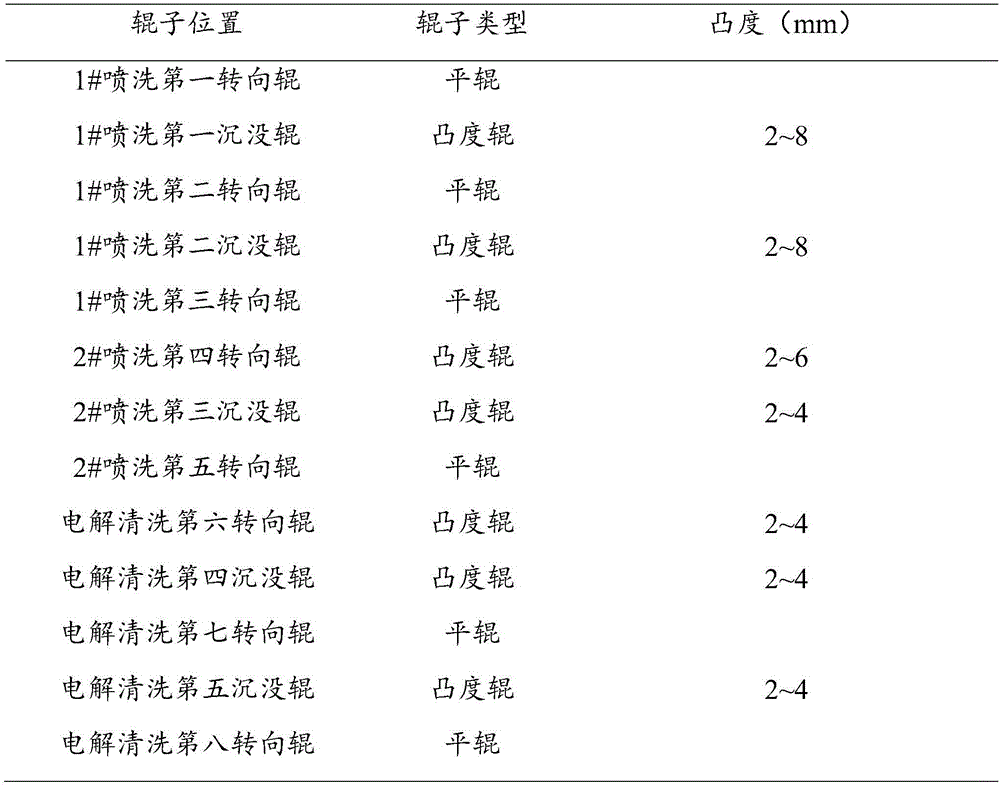

[0032] Specifically, as shown in Table 1, the roller system in the cleaning section...

Embodiment 2

[0058] Corresponding to Embodiment 1, this embodiment also provides a device for preventing strip deviation, such as figure 2 As shown, the device includes: a receiving module 21 and a determining module 22; wherein,

[0059] The receiving module 21 is used to receive the convexity value and the preset tension value of the steering roller and the sinking roller in the roller system of the cleaning section; the determination module 22 is used to reduce the cylinder deviation correction of the roller system according to the convexity value According to the tension value, ensure that the wrap angle between the strip steel and the roll system in the cleaning section is in a stable state.

[0060] Specifically, in order to improve the self-correction ability of the roller system in the cleaning section, the deviation correction amount of the strip running at high speed in the cleaning section is reduced. According to the principle of roller effect, the receiving module 21 receive...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com