Method of controlling the fuel distribution among different stages of a gas turbine combustion chamber

A fuel distribution, gas turbine technology, applied in the direction of control combustion, combustion method, combustion chamber, etc., can solve the problems of flame extension, pulsation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

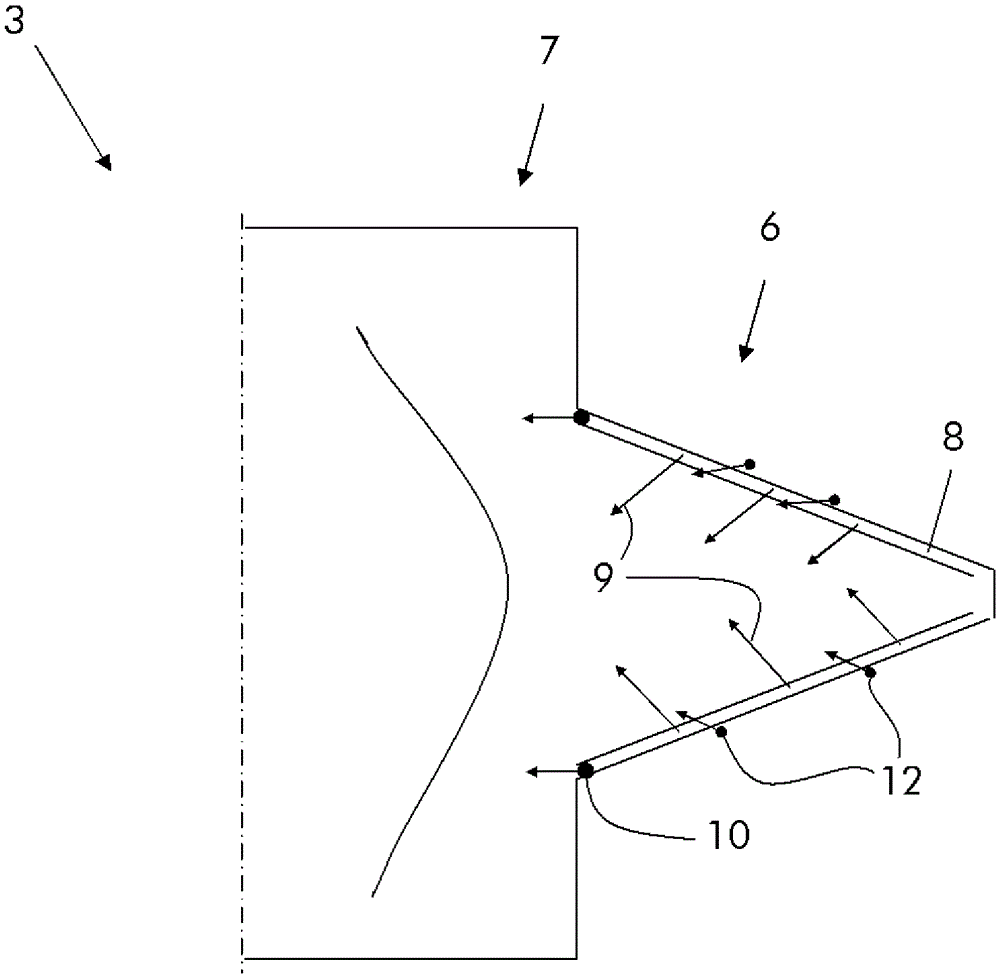

[0033] Referring to the drawings, these show a gas turbine 1 with a compressor 2 for compressing an oxidant such as air, a combustor 3 for combusting the fuel with the compressed oxidant to produce hot gas, and for expanding the hot gas and collecting Turbine 4 of mechanical work.

[0034] The combustion chamber may be of any type, in the following reference is made to a combustion chamber arranged for carrying out premixed combustion.

[0035] The combustion chamber 3 has one or more burners 6 connected to burners 7 . The incinerator 6 has a substantially conical shape with a notch 8 extending axially on the conical surface for the supply of an oxidant 9 into the incinerator 6 .

[0036] The burner 6 is also provided with nozzles for fuel supply.

[0037] The first nozzle 10 defines a first fuel supply stage and is provided at the end portion of the burner 6 in order to supply fuel into the burner 7 for combustion; the fuel supplied via the first stage undergoes diffusion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com