Distribution building OPGW optical cable down-lead inlet method

A technology of optical cable and cable layer, which is applied in the direction of optical fiber/cable installation, optics, light guide, etc. It can solve the problems that the roof does not have buried pipes through the wall, and the joint box is exposed outside, so as to achieve waterproof effect, improve safety and reliability, The effect of short trace distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

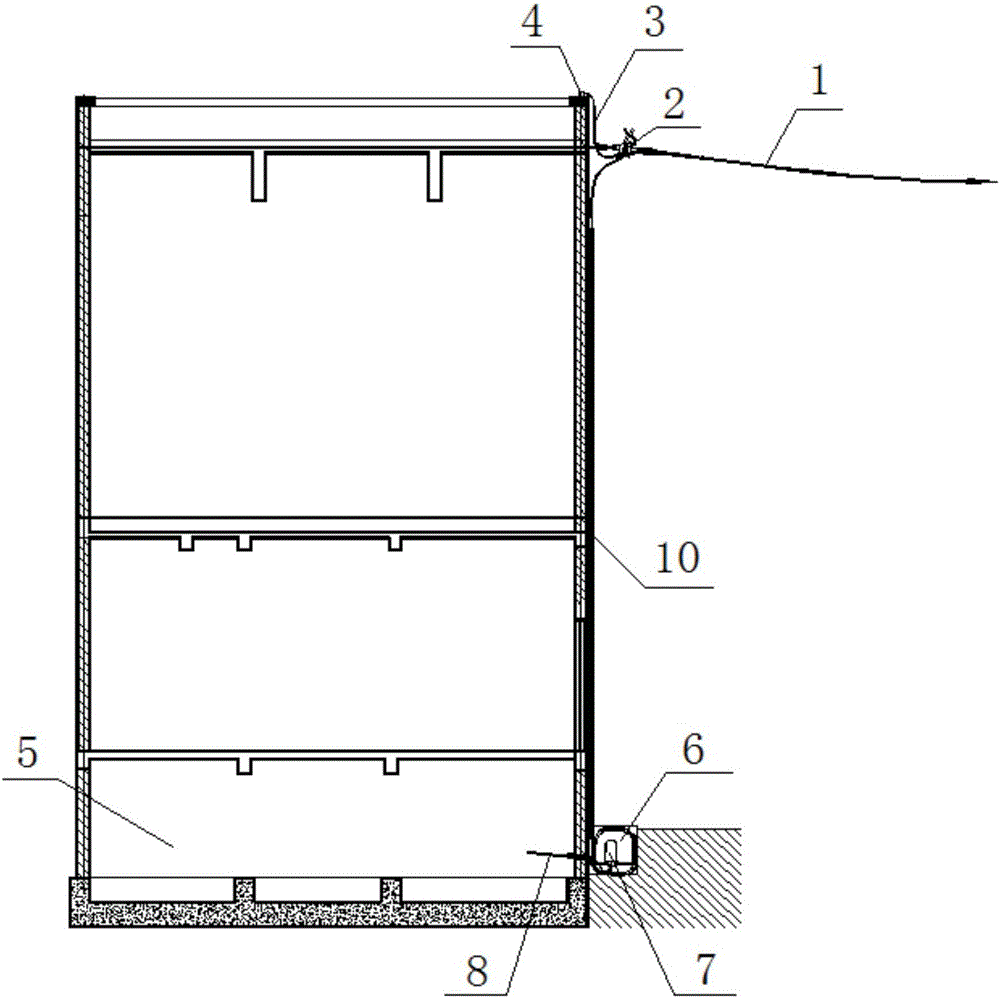

[0037] see Figure 1 to Figure 3 , the method for leading the OPGW optical cable of the power distribution building into the station provided by this embodiment includes the following steps:

[0038] S1: Fix the OPGW optical cable 1 on the outer wall through the tension string 2, and connect the tension string ground wire 3 of the tension string 2 to the ground wire 4 of the power distribution building on the roof;

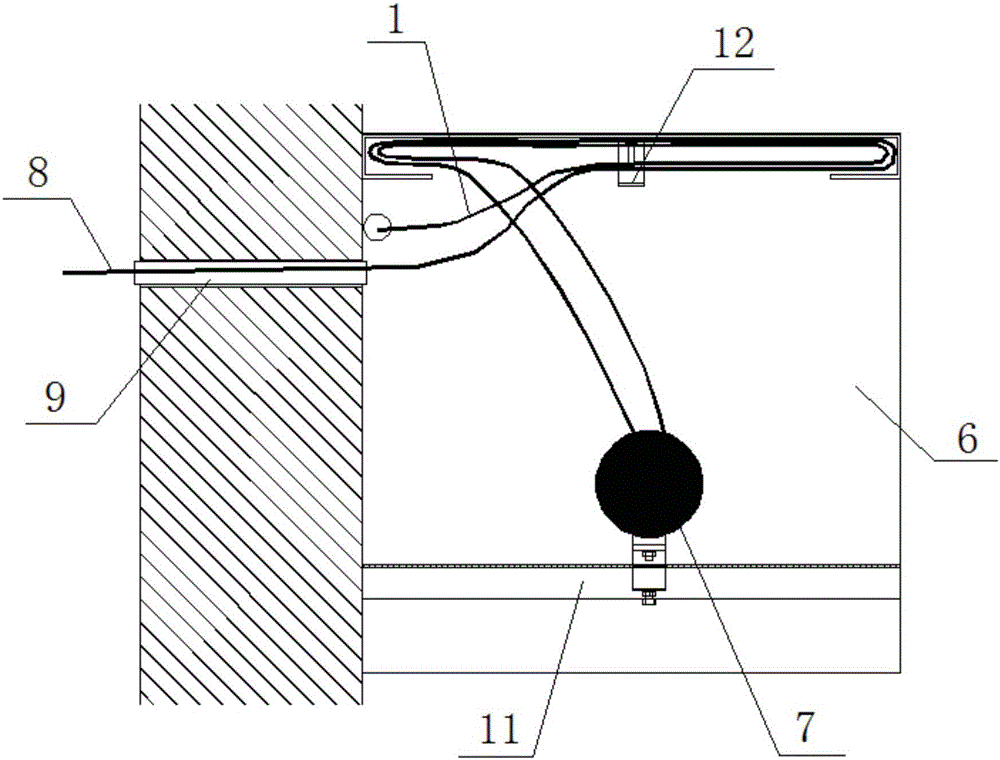

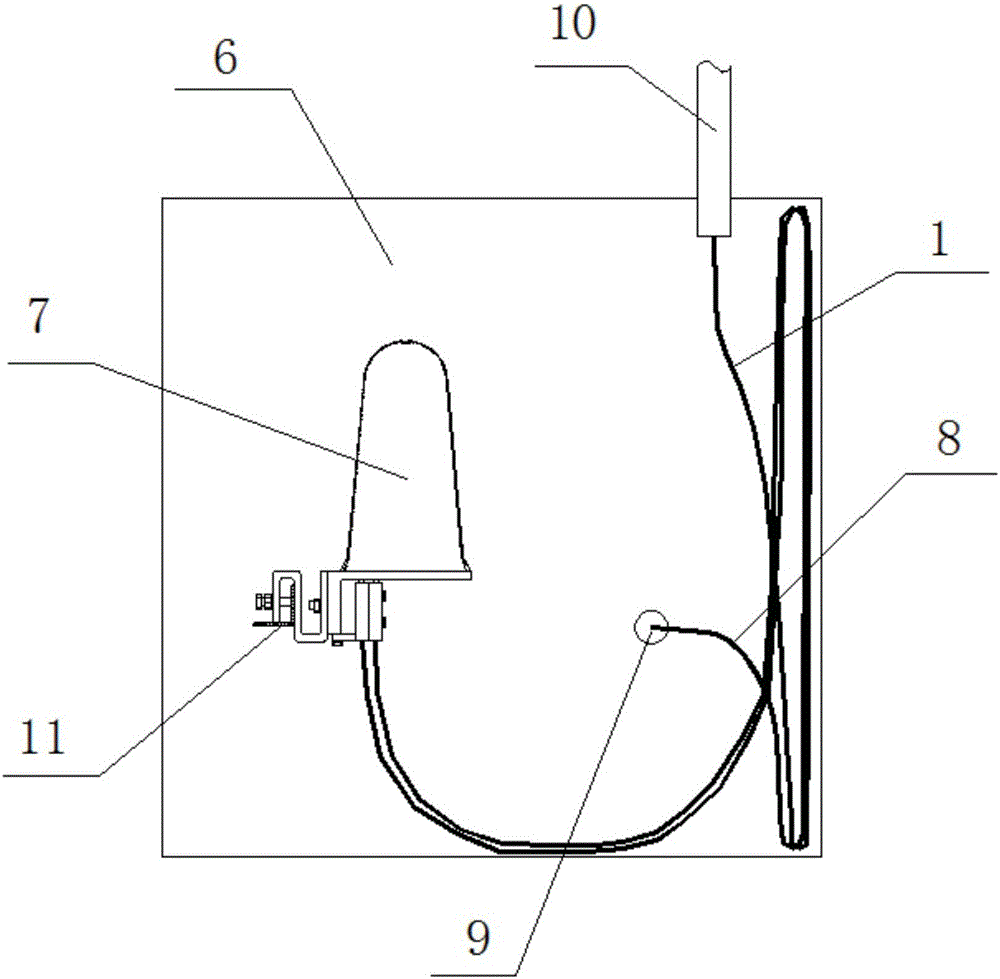

[0039] S2: Make a joint well 6 along the extension direction of the cable layer 5 on the ground close to the wall, and a joint box 7 and a guide optical cable 8 are arranged in the joint well 6;

[0040] S3: perforate the buried pipe on the wall at the joint well 6, so as to obtain the pipeline 9 connecting the inside and outside of the power distribution building;

[0041] S4: Lead the OPGW optical cable 1 down to the joint well 6 along the wall, and switch and connect with the guide optical cable 8 in the joint well 6 in the joint box 7;

[0042] S5: Distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com