A mining environment reconstruction method based on the recycling of waste tires

A waste tire and environmental technology, applied in mining equipment, earth-moving drilling, safety devices, etc., can solve the problems of free surface peeling or even collapse of the backfill, low construction efficiency, and cumbersome implementation process, achieving good structural performance and improving construction. Efficiency, the effect of improving tensile properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below by way of examples. Through these descriptions, the features and advantages of the present invention will become more apparent. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them.

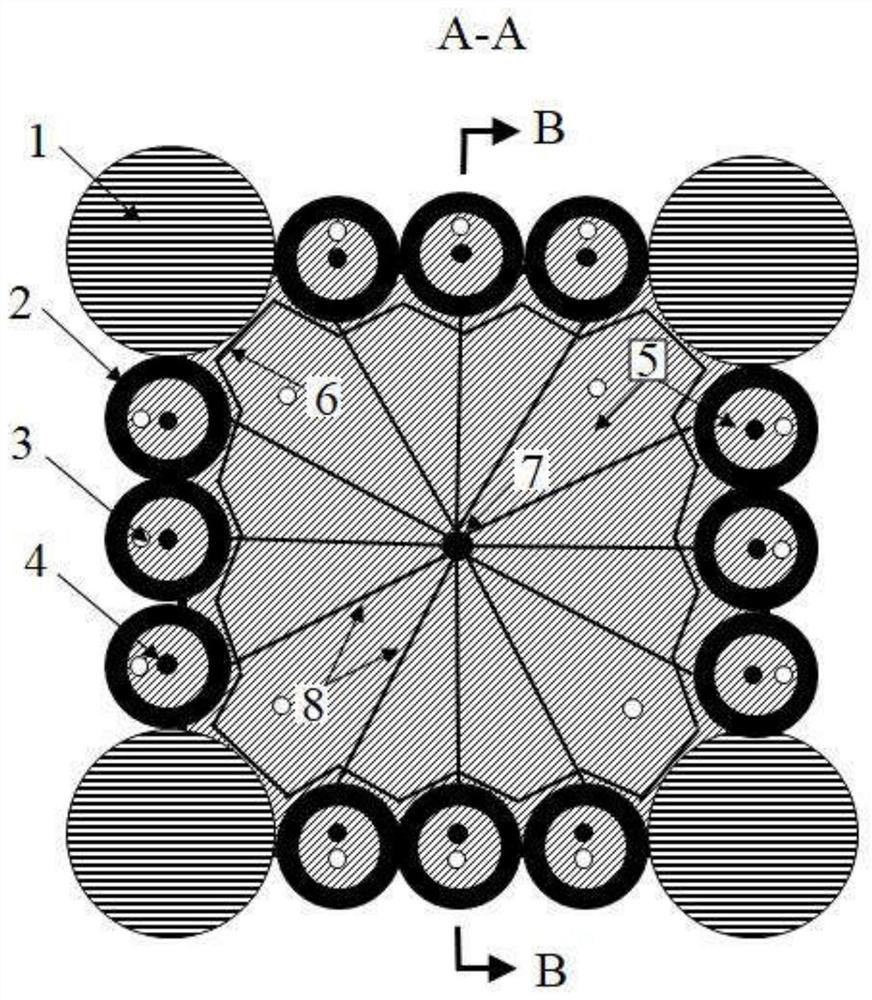

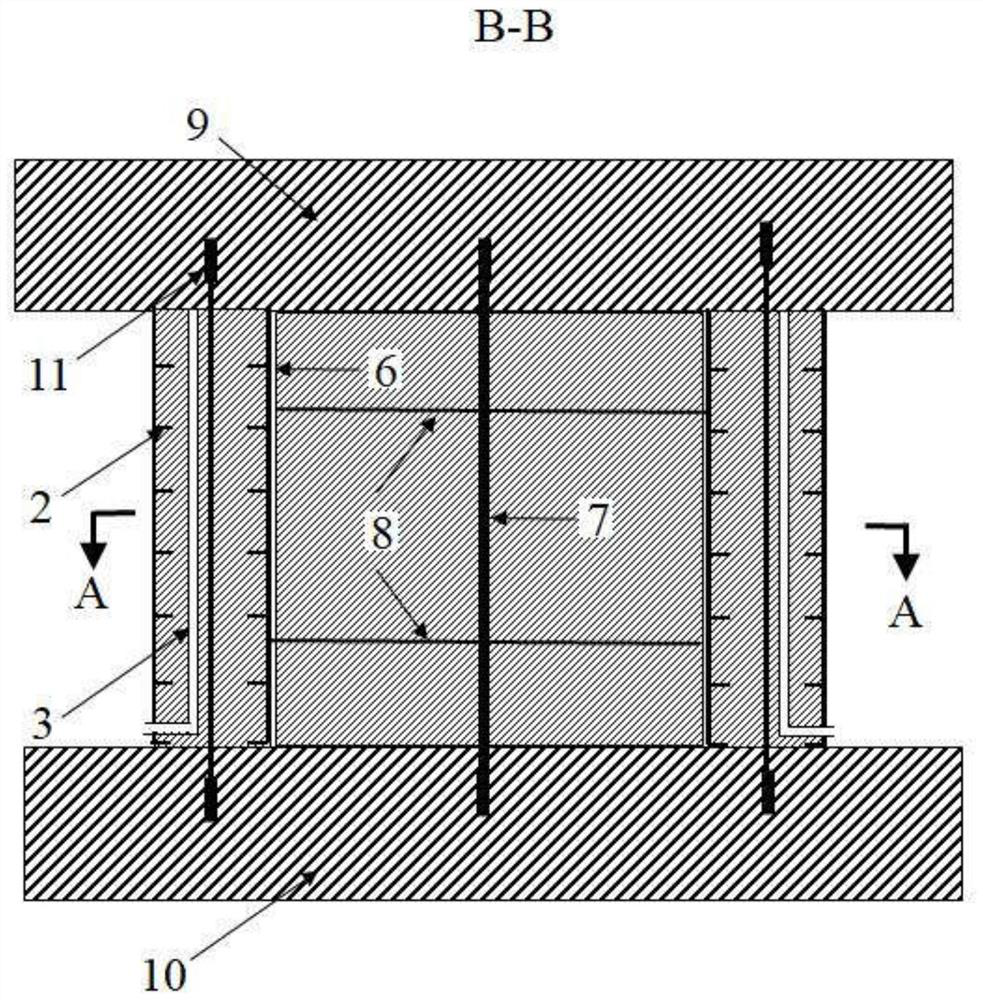

[0030] Such as Figure 1-2 As shown, the mining environment reconstruction method based on waste tire recycling of the present embodiment includes the following steps:

[0031] S1: overlapping and gluing a plurality of waste tires 2 of the same type together to form a series of waste tires, and the cavity of the series of waste tires constitutes a tire filling area;

[0032] S2: Use the ore pillar 1 as the corner, use a plurality of glued waste tire series arranged side by side between the adjacent ore pillars 1 as the wall to form the filling frame, and form the central filling area through the filling frame;

[0033] S3: Vertically arrange the water filter pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com