Asynchronous motor rotor time constant adjusting method

A technology of rotor time constant and adjustment method, applied in the control of generator, motor generator control, electronic commutation motor control, etc., can solve the problem of no torque test, etc., and achieve the effect of high efficiency and less time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

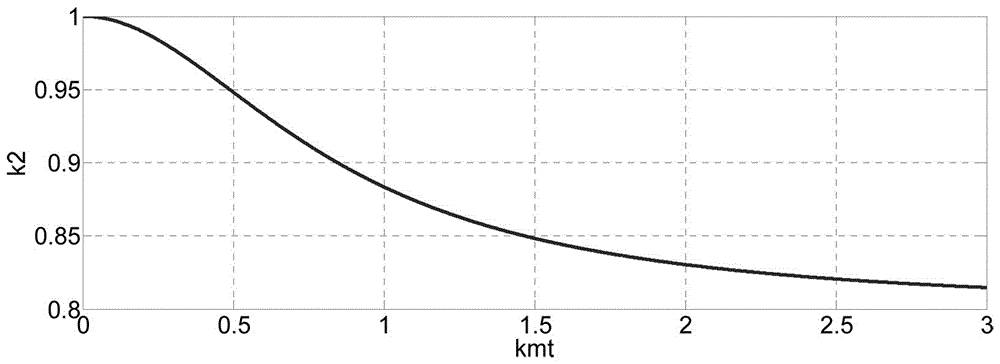

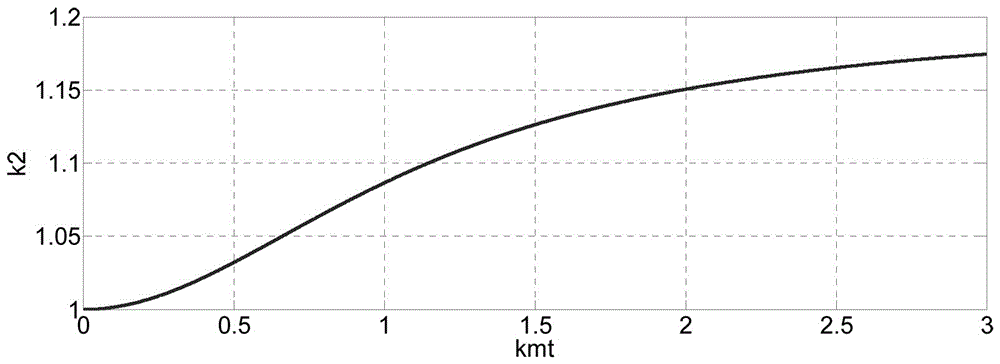

[0025] In some practical applications, there may be no torque test or similar torque test equipment. In this case, it can be considered to roughly judge whether the rotor time constant is accurate by observing the modulation coefficient of the frequency converter when the motor is running, and Give the adjustment method.

[0026] The present invention is mainly applicable to the occasions where there is no torque tester or torque test equipment in the vector control of asynchronous motors, and the deviation of the rotor time constant is relatively large, and the accuracy of the rotor time constant can be roughly judged by observing the modulation coefficient of the frequency converter when the motor is running , adjust the rotor time constant according to the rotor time constant offset coefficient curve.

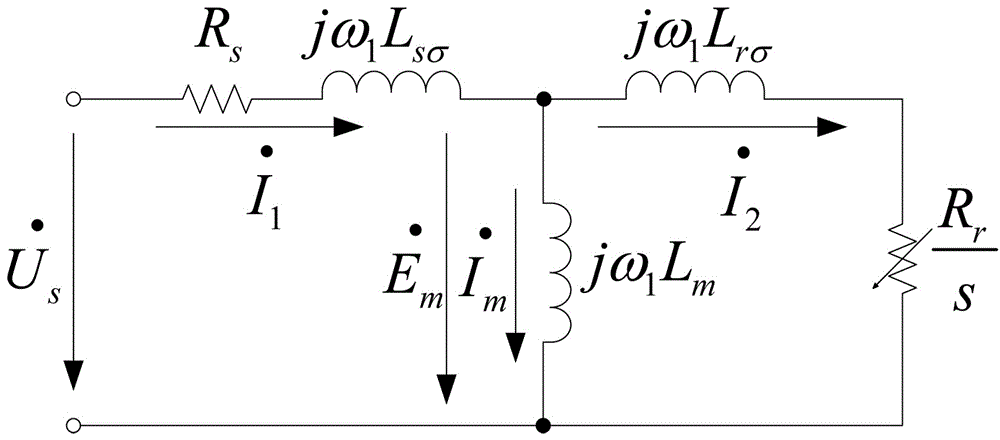

[0027] figure 1 Shown is the equivalent circuit dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com