Asynchronous motor parameter online correction method based on rotor flux observer

A technology of rotor flux linkage and asynchronous motor, which is applied in the direction of electronic commutation motor control, control generator, motor generator control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

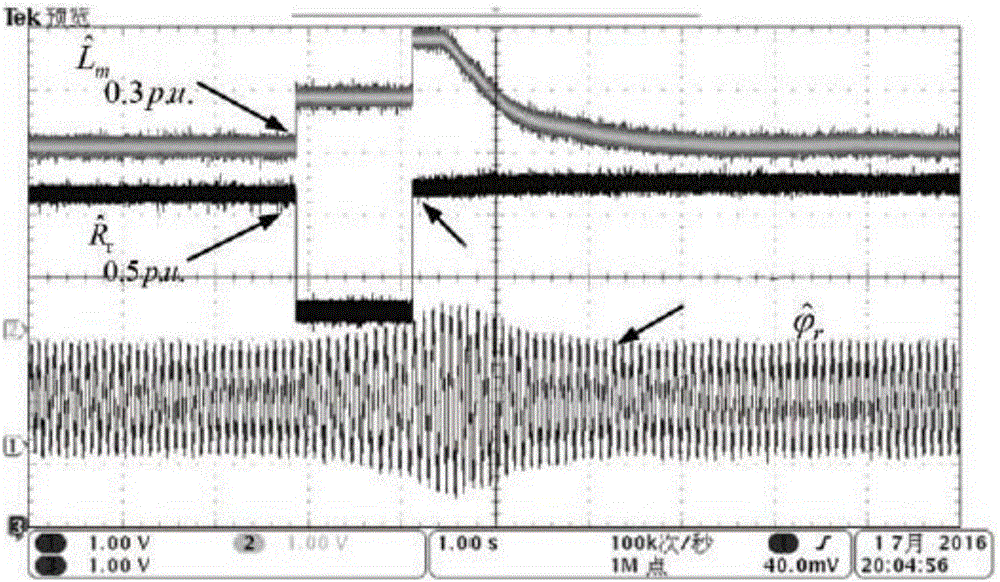

Examples

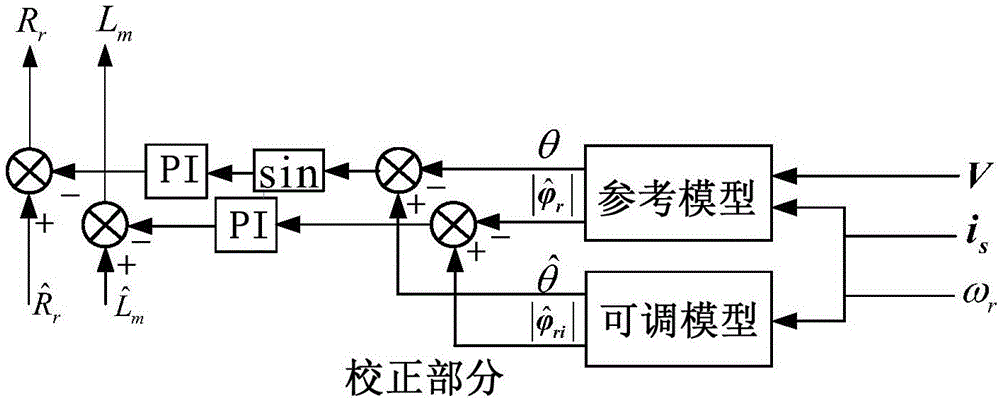

Embodiment Construction

[0080] The present invention will be further described below with reference to the drawings and embodiments.

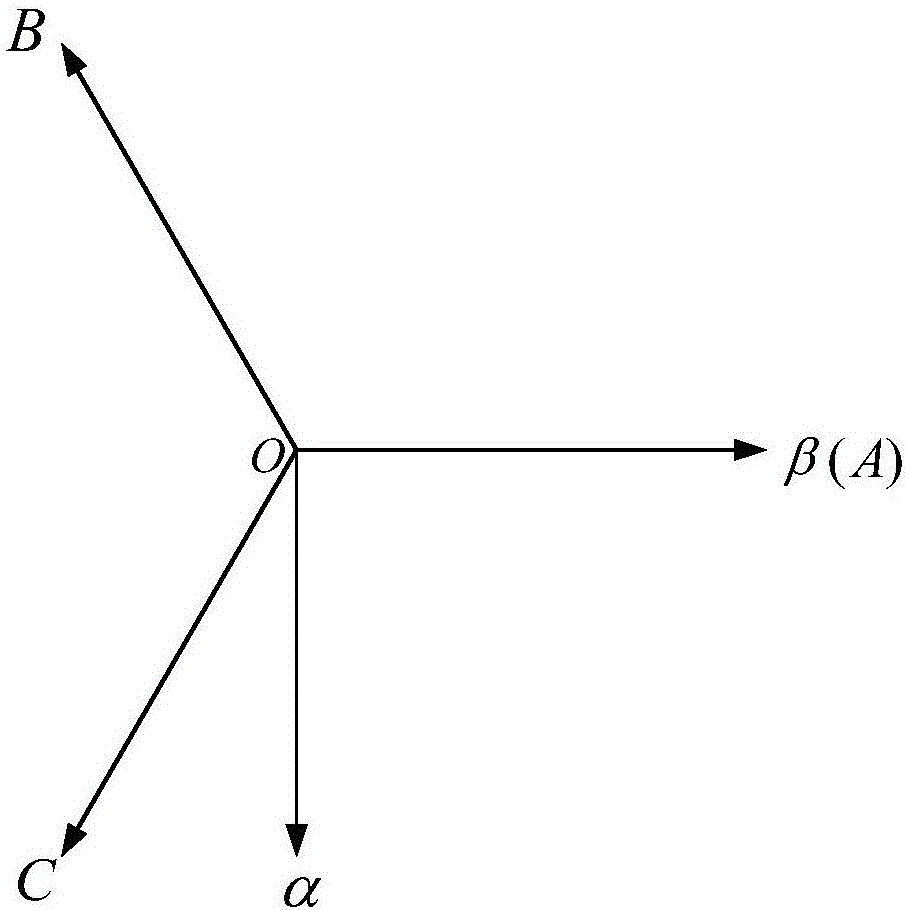

[0081] In the signal acquisition part, the stator voltage vector V and the stator current vector i are obtained by sampling the stator line voltage U ab , Stator line voltage U cb , Stator A phase current i A , Stator B phase current i B , Stator C phase current i C , And obtained by transforming the three-phase stationary coordinate system to the two-phase stationary coordinate system, the actual rotor electrical angular velocity ω r It is obtained by photoelectric rotary encoder. This embodiment proceeds as follows:

[0082] Step 1. Collect the stator voltage vector V, stator current vector i, and rotor electrical angular velocity ω of the asynchronous motor in the static coordinate system αβ r ;

[0083] Step 2. Establish the state space expression of the asynchronous motor in the static coordinate system αβ as:

[0084]

[0085] In formula (1), e is the back-EMF vector, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com