Asynchronous motor rotor resistance and excitation inductance decoupling correction method

A technology of excitation inductance and rotor resistance, which is applied in the control of generators, motor generators, electronically commutated motors, etc., can solve problems such as failure to improve, and the impact of correction schemes on transient performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0114] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

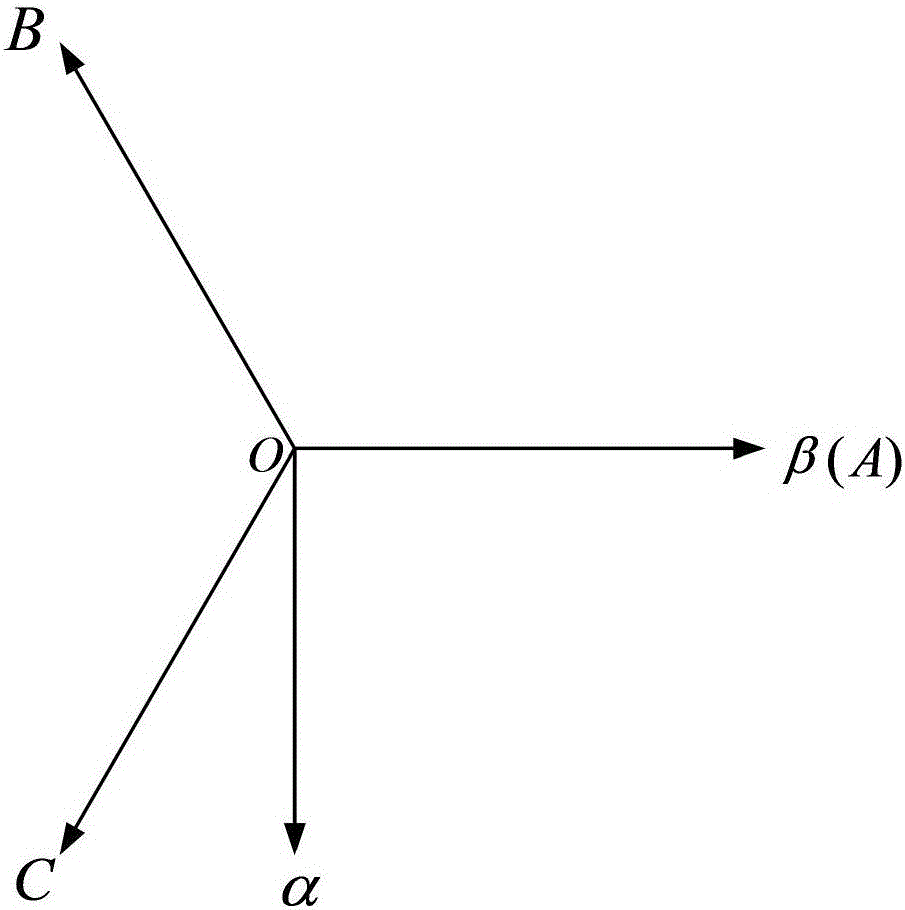

[0115] In the signal acquisition part, the stator voltage vector V and the stator current vector i are obtained by sampling the stator line voltage U ab , stator line voltage U cb , Stator A-phase current i A , Stator B-phase current i B , Stator C-phase current i C , and obtained through the transformation from the three-phase stationary coordinate system to the two-phase stationary coordinate system, the actual rotor electrical angular velocity ω r It is obtained by using a photoelectric rotary encoder.

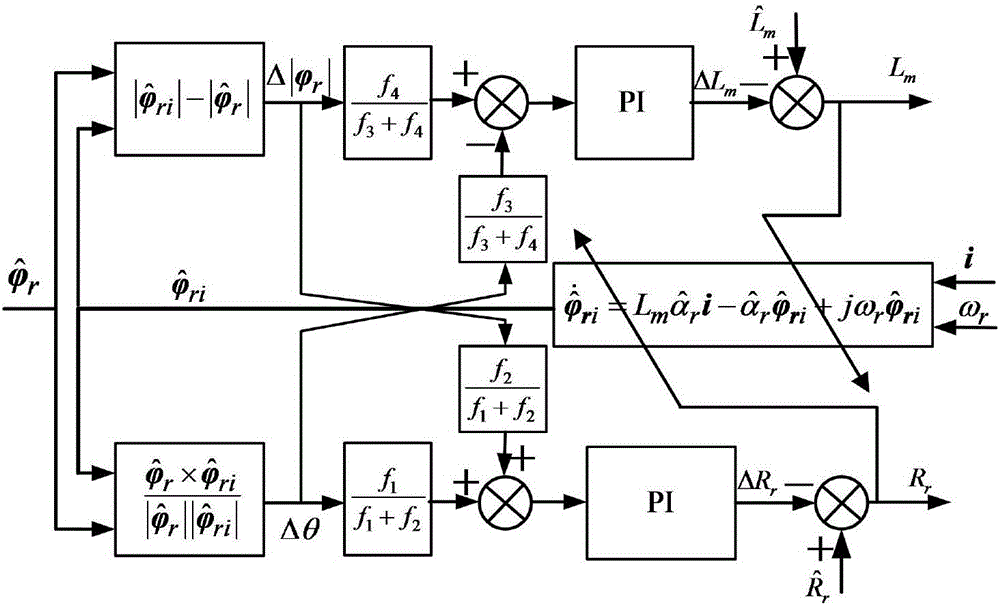

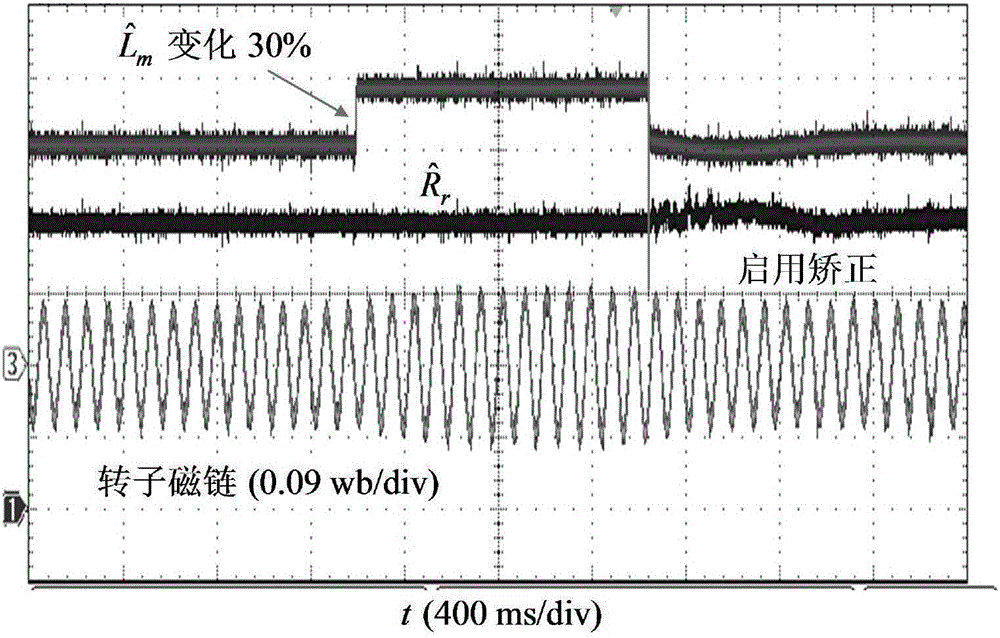

[0116] figure 1 is the static coordinate system selected in the present invention, figure 2 It is a structural block diagram of the rectification principle in the present invention. see figure 1 and figure 2 , this embodiment is carried out according to the following steps.

[0117] Step 1, collect the stator voltage vector V, stator cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com