Cylinder type moisture regaining machine for tea manufacturing

A reconditioning machine and drum type technology, applied in the field of drum type tea reconditioning machines, can solve the problems affecting reconditioning quality, low efficiency, and the uniformity of reconditioning needs to be improved, so as to ensure reconditioning quality, improve reconditioning efficiency, and shorten reconditioning. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with specific examples.

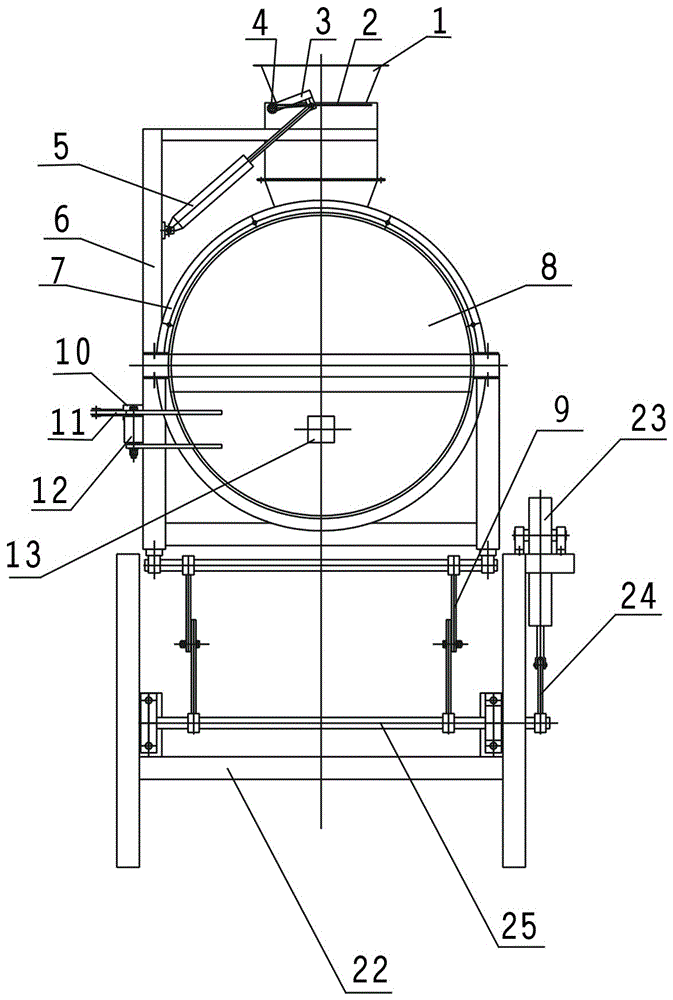

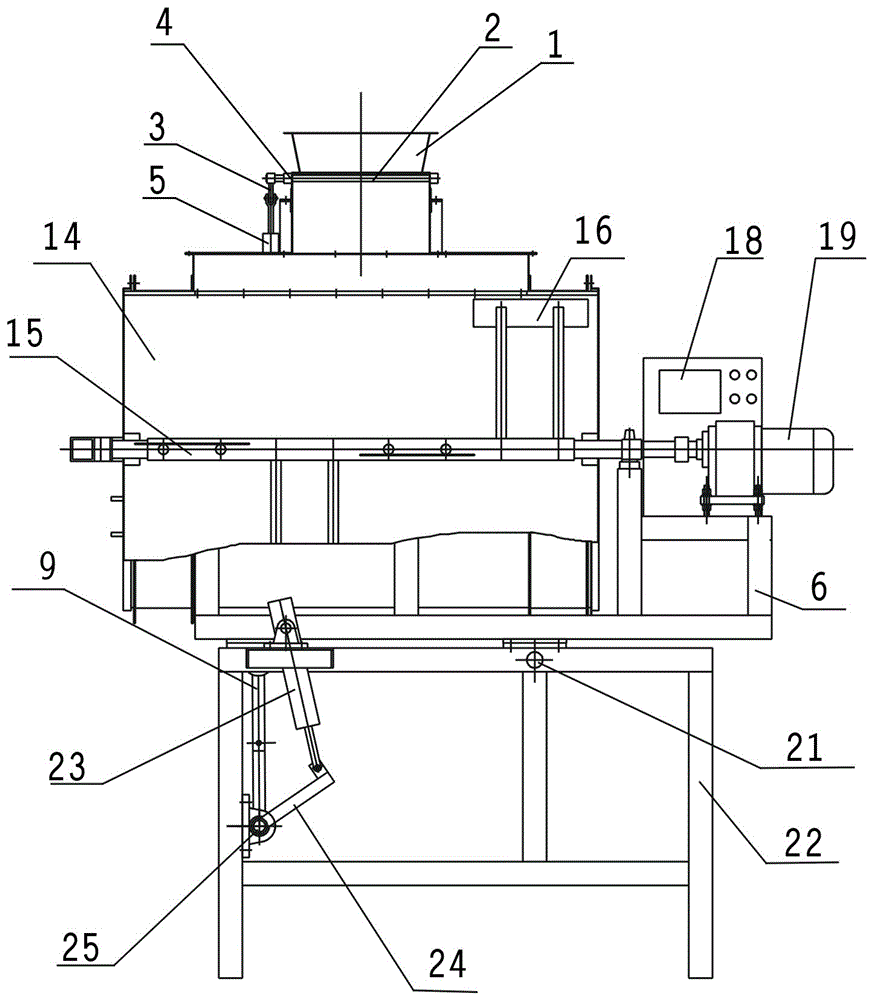

[0015] refer to figure 1 with figure 2 , the feeding mechanism of the drum-type tea making machine is located on the upper part of the drum 14. The feeding mechanism includes a feeding hopper 1, a door panel 2, a connecting rod I3, a rotating shaft I4 and a cylinder I5. The door panel 2 is arranged in the feeding hopper 1. The door panel 2 is connected with the rotating shaft I4, the cylinder I5 is connected with the rotating shaft I4 through the connecting rod I3, the cylinder I5 is fixed on the frame 6, and the feeding hopper 1 is connected with the upper part of the drum 14. The leaf turning mechanism is located in the drum 14, and the leaf turning plate 16 in the leaf turning mechanism is connected on the central shaft 15, and the central shaft 15 is connected with the motor 19. The cylinder 14 is fixed on the frame 6 by the hoop 7 and the front end of the cylinder 14 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com