Breathable shoe sole high in forming efficiency and breathable shoe

A high-efficiency, breathable shoe technology, applied in the field of daily life, can solve problems affecting shoe quality, prolong gluing time, affect efficiency, etc., achieve the effects of shortening gluing time, ensuring molding quality, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

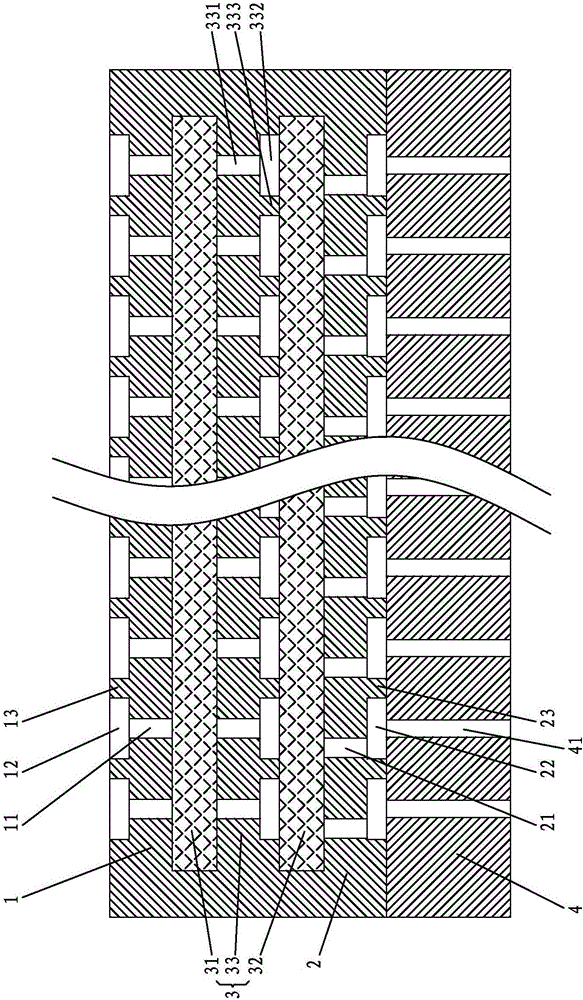

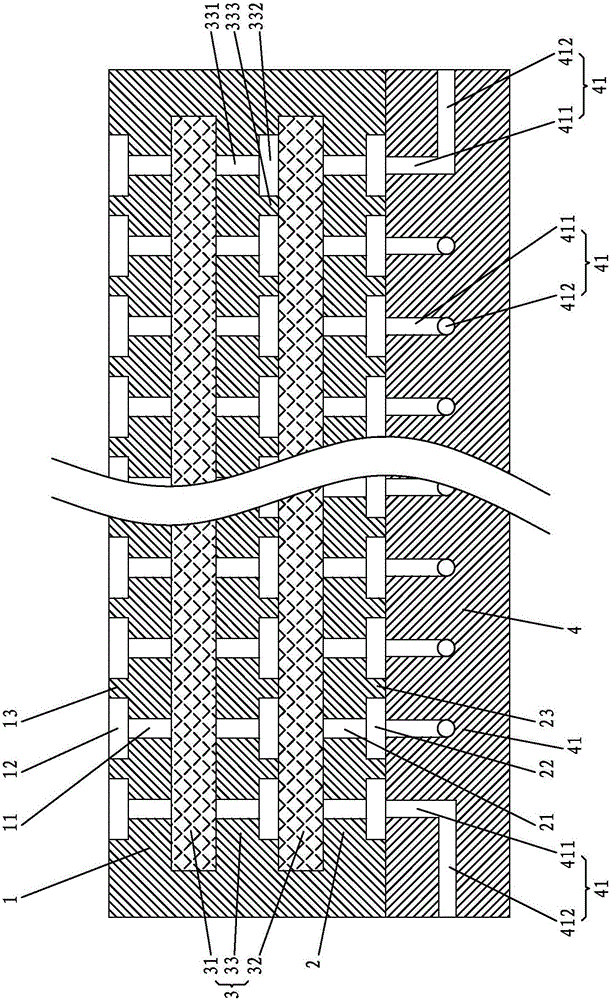

[0030] A breathable sole with high molding efficiency of the present invention, such as Figure 1-3 As shown, it includes an upper Internet layer 1, a lower Internet layer 2, and an intermediate layer 3 located between the Internet layer 1 and the lower Internet layer 2. The upper mesh layer 1 has upper mesh holes 11, and the lower mesh layer 2 has lower mesh holes 21.

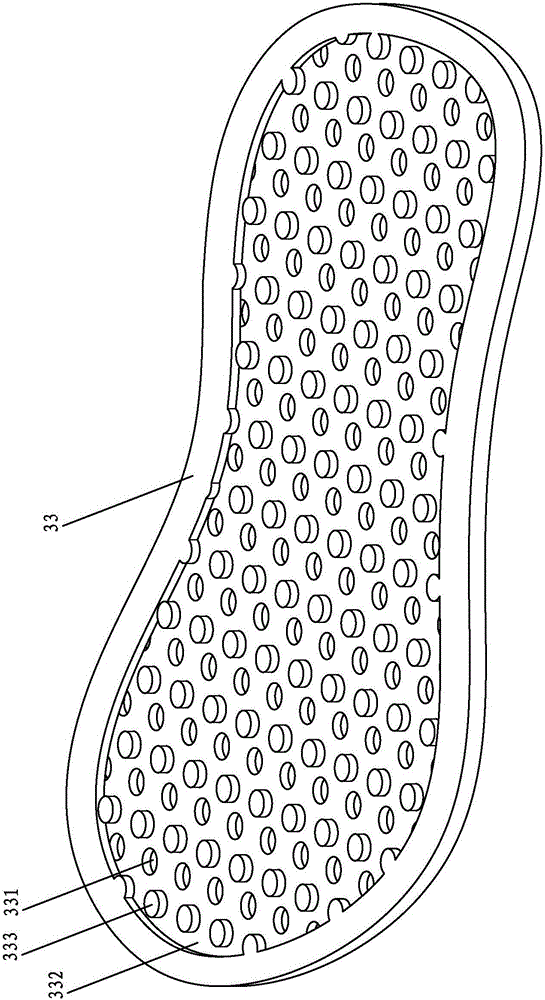

[0031] The middle layer 3 includes an upper air-permeable waterproof layer 31 above, a lower air-permeable waterproof layer 32 below, and an elastic supporting layer 33 arranged between the upper air-permeable waterproof layer 31 and the lower air-permeable waterproof layer 32 . Both the upper air-permeable and waterproof layer 31 and the lower air-permeable and waterproof layer 32 are layer structures made of air-permeable and waterproof materials, and have the fun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com