Cabinet body manufacture technique

A manufacturing process and cabinet body technology, applied in the field of cabinet cabinet body manufacturing process, can solve the problems of easy water inflow and expansion, large gaps, difficult installation, etc., and achieve the effect of solving swelling and mildew

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings and specific embodiments.

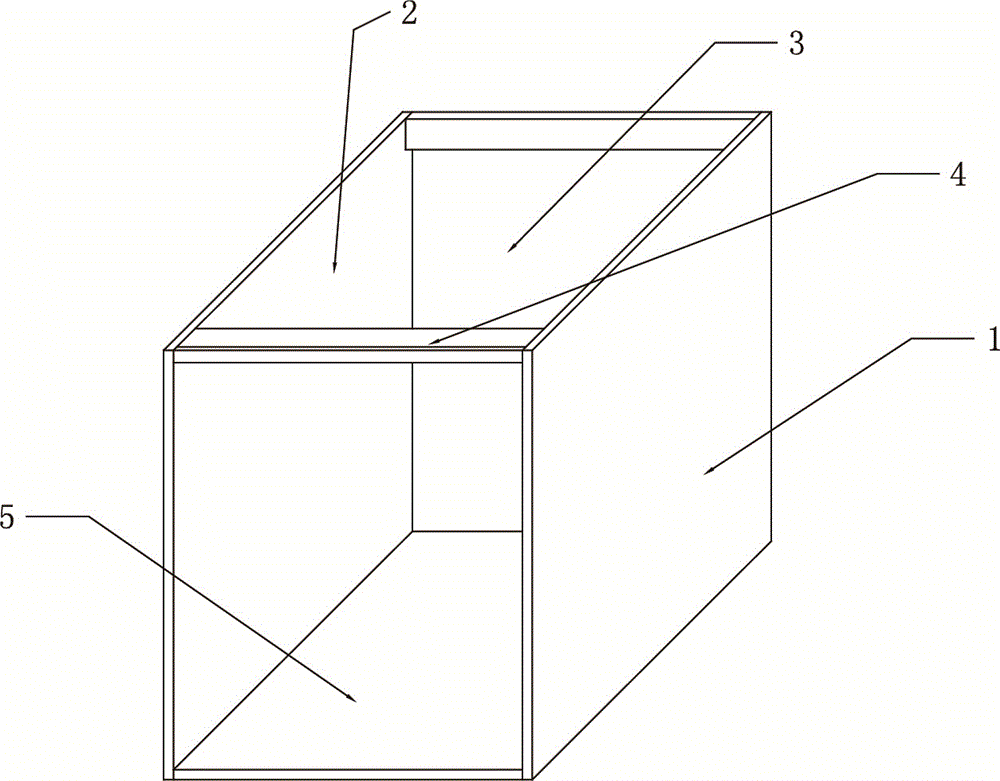

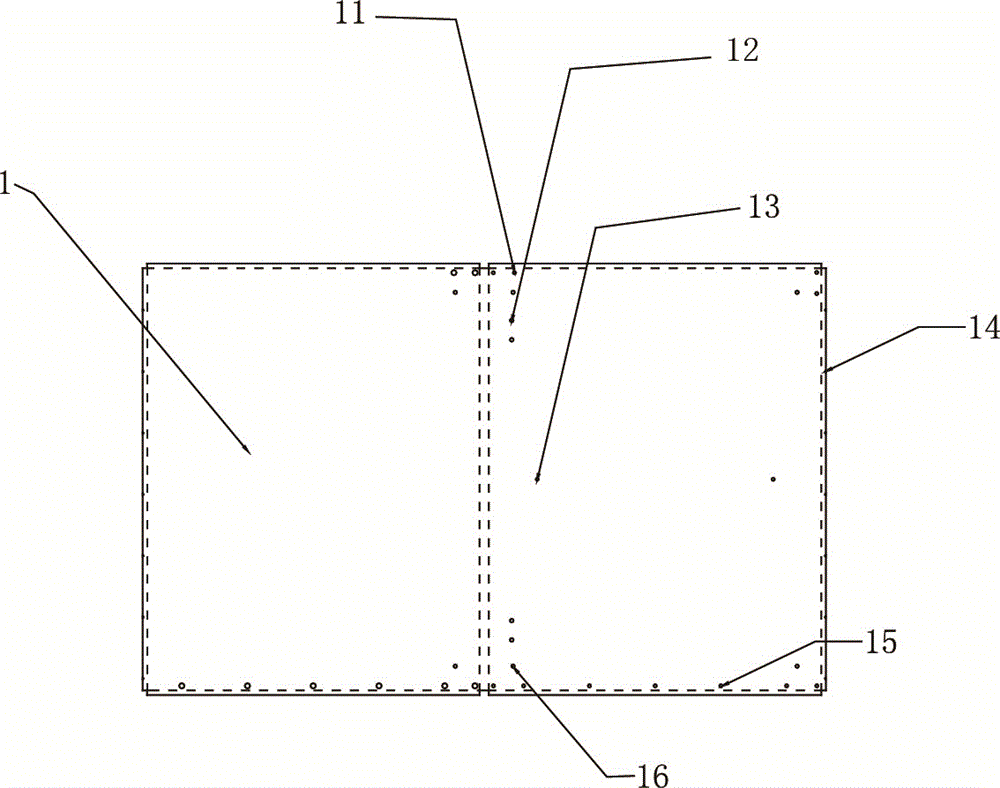

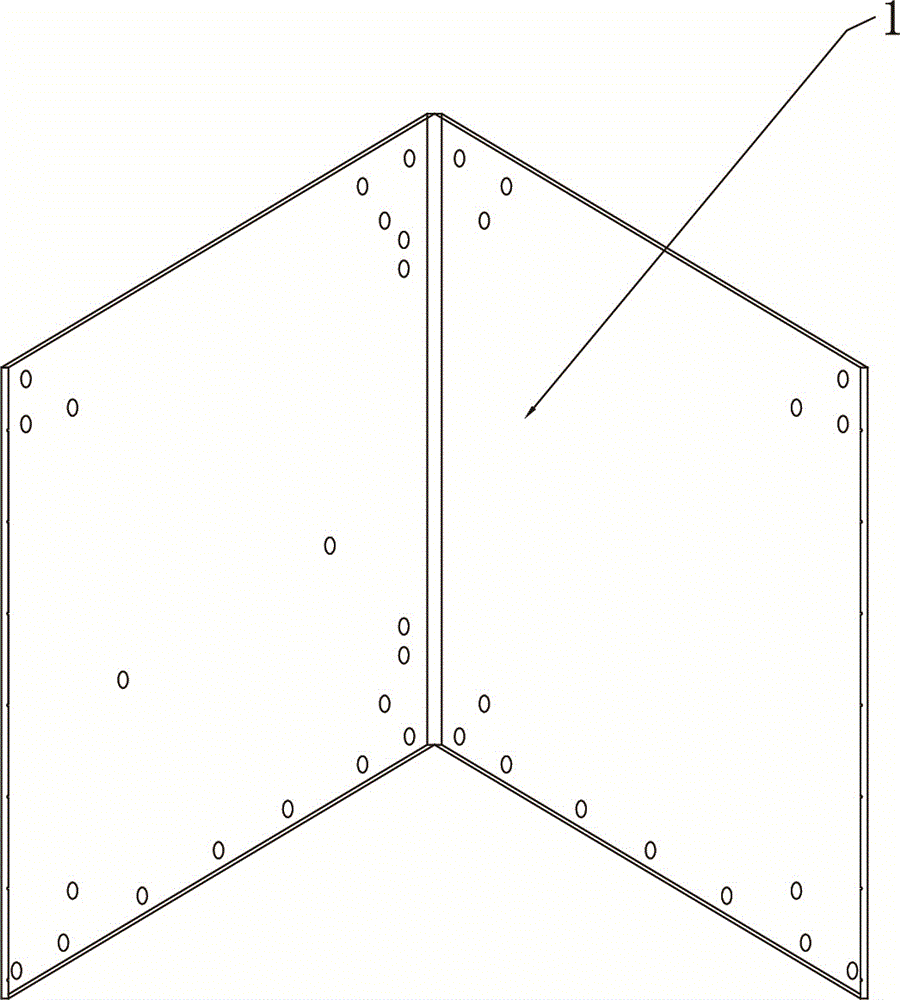

[0028] A cabinet body manufacturing process, including the following steps: a: processing the left side plate 2 and the right side plate 1; b: processing the bottom plate 5, the back integrated plate 3 and the front cross head 4; c: the right side plate 1, The left side plate 2, the bottom plate 5, the back integrated plate 3 and the front cross head 4 are assembled into a cabinet. The right side plate 1 in the step a is formed by bending a piece of stainless steel steel plate, and is opened in the middle of the stainless steel plate Two V-shaped grooves. The stainless steel plate is divided into two modules by two V-shaped grooves. Each module is composed of four faces, including the middle face and the other three faces surrounding the middle face. The other three Both sides need to be grooved first and then bend, then one of the two V-grooves is bent at 90 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com