Oil injection equipment

A technology of equipment and fuel injection system, which is applied in the field of automatic control, can solve the problems of increasing labor costs, increasing production efficiency, and not being able to adapt to large-scale industrial production, so as to achieve the effects of improving work efficiency, reducing quantity, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

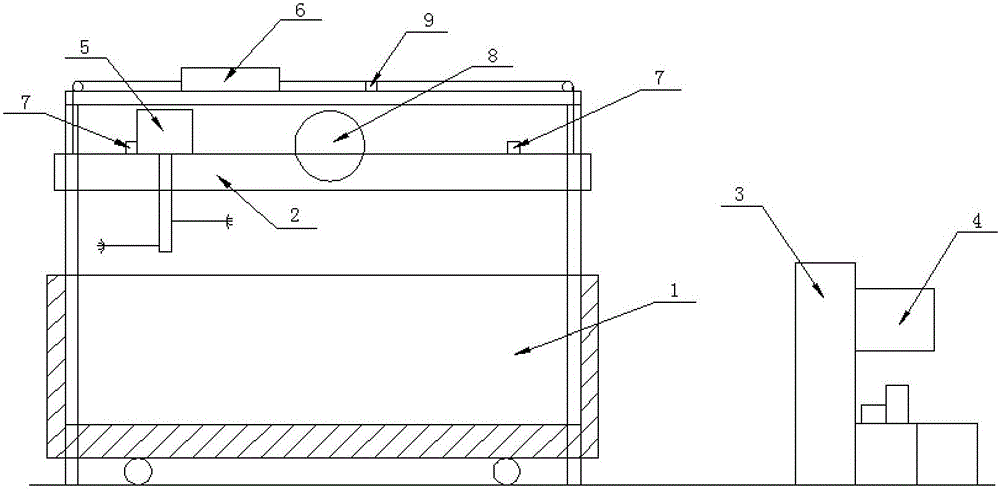

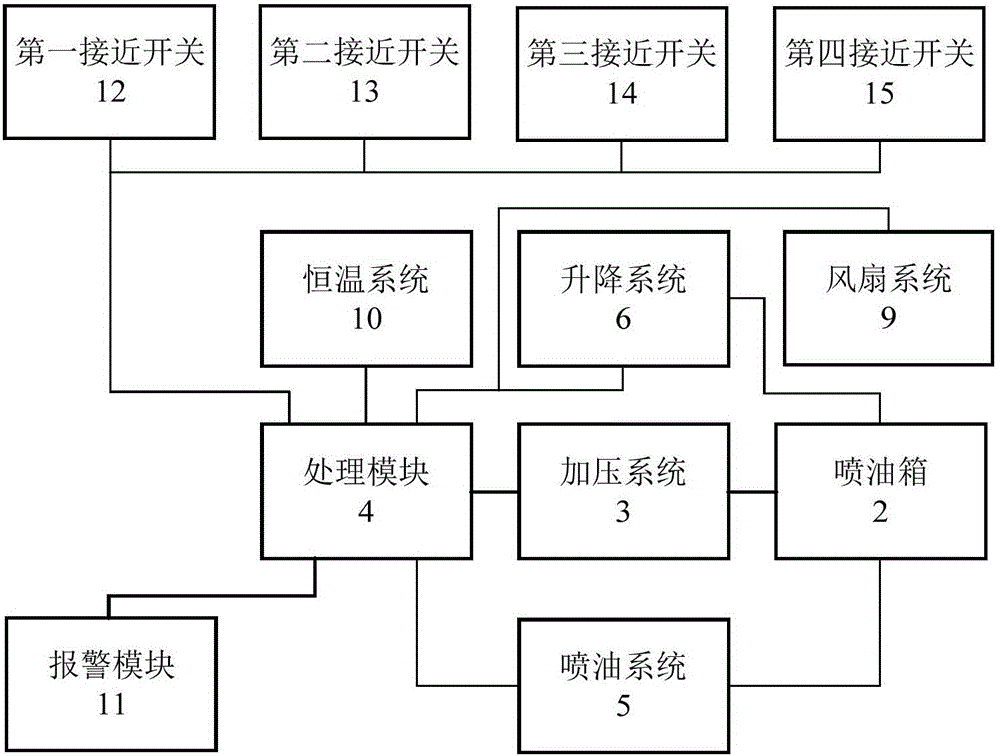

[0054] see figure 1 and figure 2 , this embodiment provides a fuel injection device, including: a support frame, a fuel injection tank 2, a fuel injection system 5, a lifting system 6 and a first positioning module 7;

[0055] The fuel injection tank 2 is connected with the lifting system 6, and is used to hold the demoulding oil to be sprayed;

[0056] The lifting system 6 is fixed on the support frame and is used to adjust the fuel injection height of the fuel injection tank 2 during the fuel injection process;

[0057] Two first positioning modules 7 are arranged on the top of the fuel injection box 2, and are used to limit the fuel injection travel area of the fuel injection system 5;

[0058] The fuel injection system 5 is fixed on the top of the fuel injection box 2 and connected with the fuel injection box 2, and is used for rotating and walking in the fuel injection walking area limited by the two first positioning modules 7 during the fuel injection process.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com