A built-in automatic coating device and method based on precious metal 3D printing

A 3D printing and coating device technology, applied in the direction of process efficiency improvement, additive manufacturing, additive processing, etc., can solve the problems of uneconomical precious metal parts, shorten the travel of powder spreading device, and fail to save powder, etc., to achieve improvement Accuracy and quality, reduced powder contamination, use of reduced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

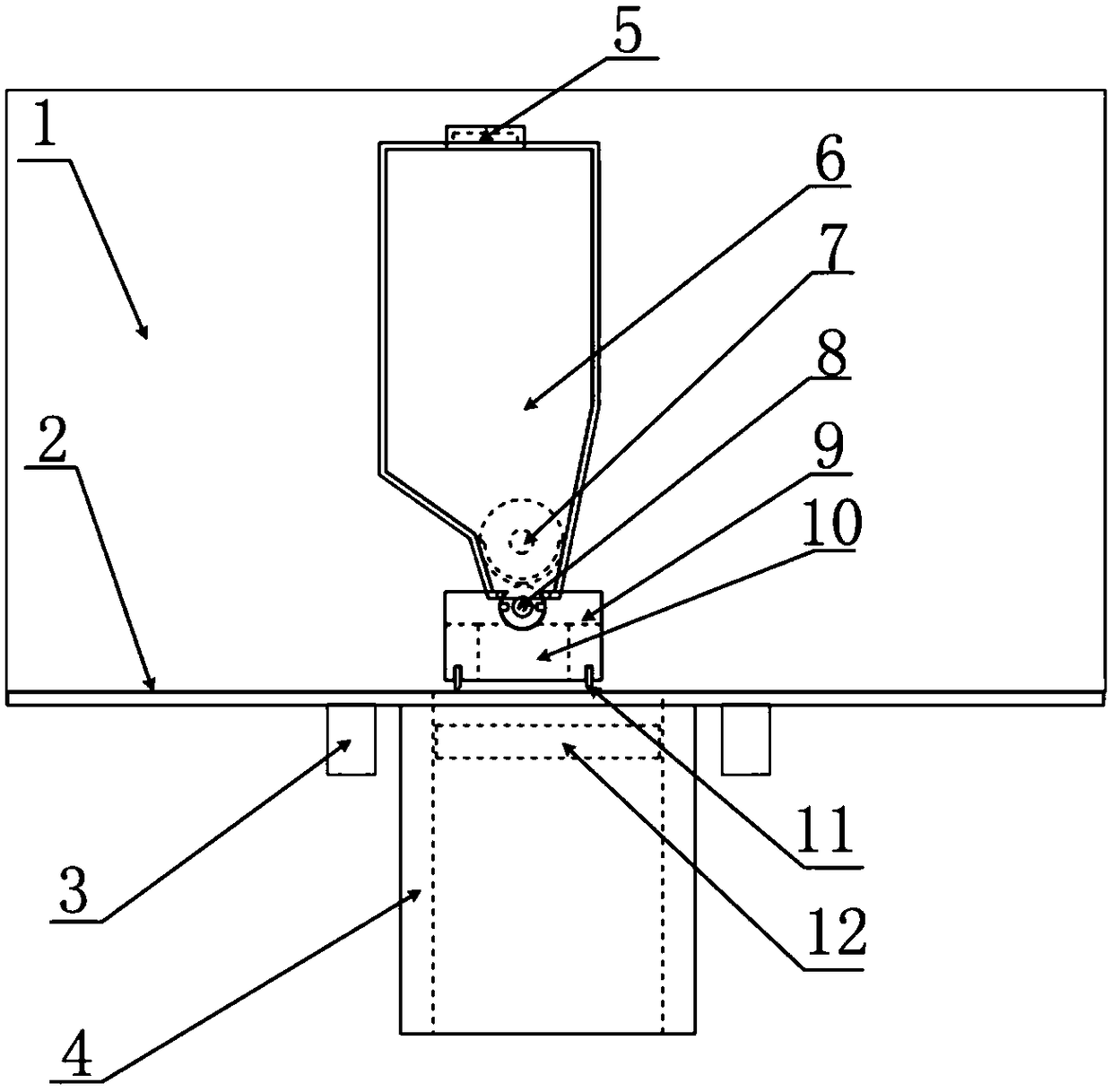

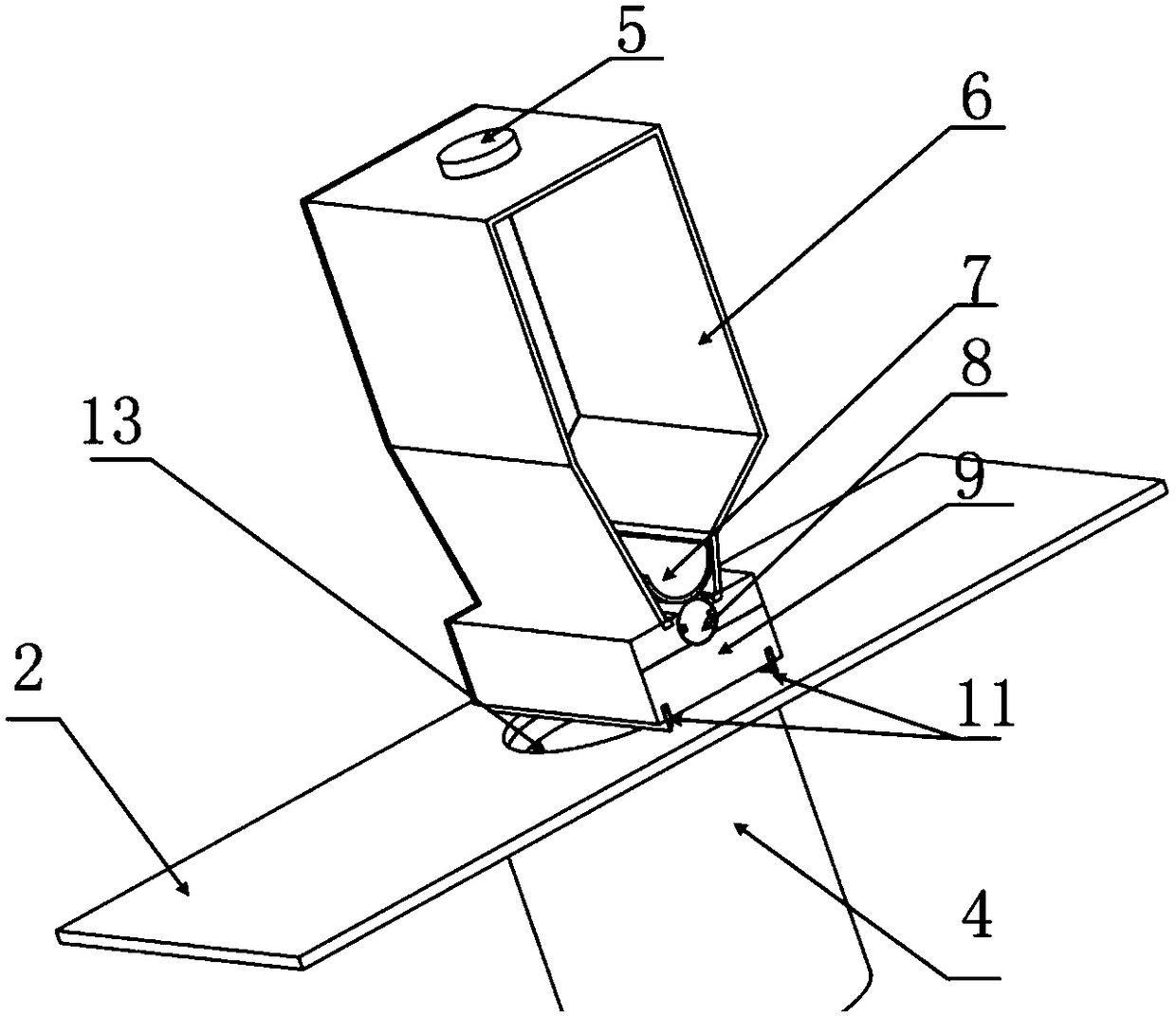

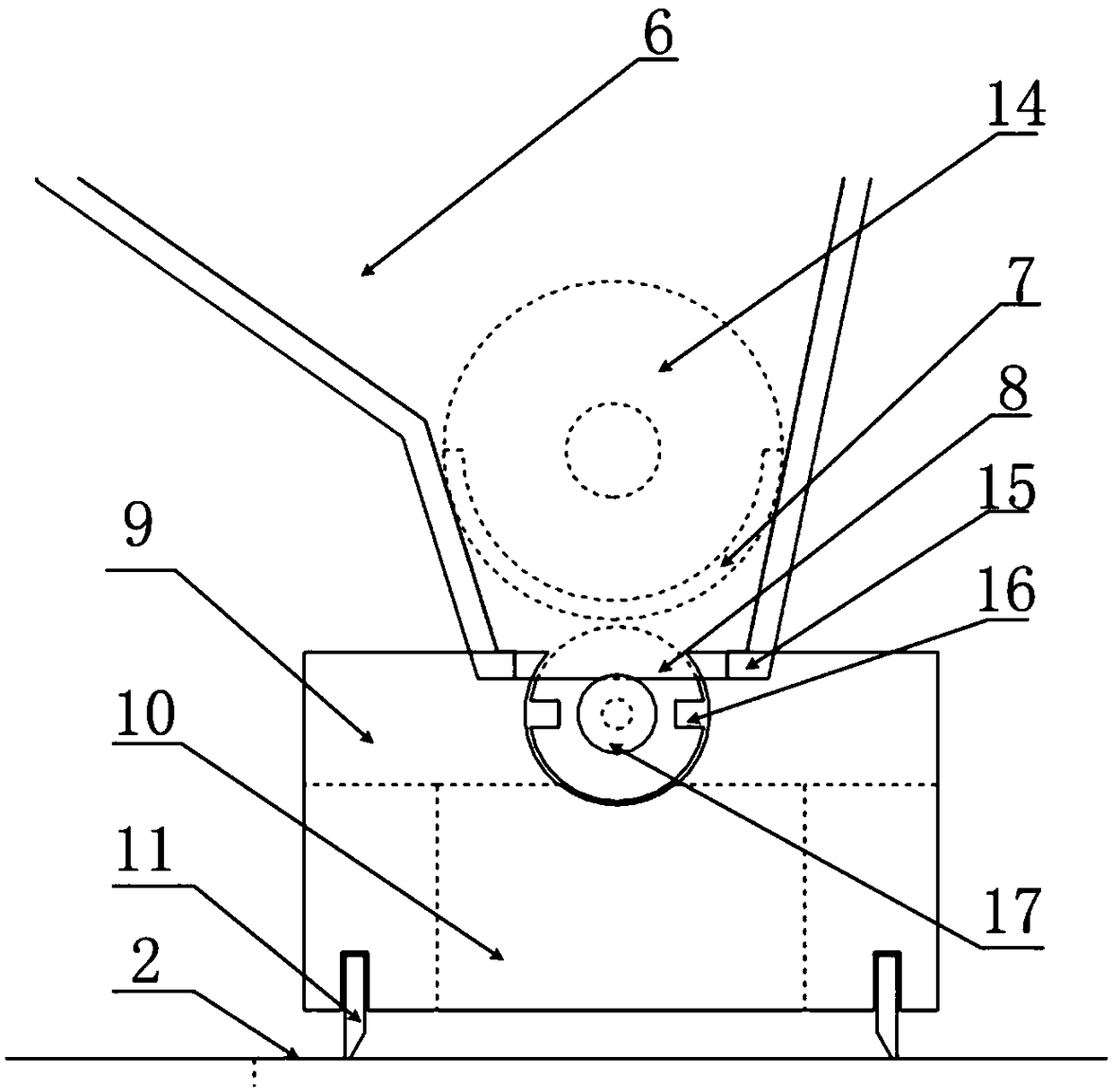

[0031] Such as Figures 1 to 3 shown. The invention discloses a built-in automatic coating device based on precious metal 3D printing, which includes a molding chamber 1, a powder spreading mechanism placed in the molding chamber 1, a reference level plate 2 placed in the molding room 1, a reference level plate placed Forming cylinder 4 below 2; the powder spreading mechanism includes a powder material box body 6; the top of the material box body 6 is provided with a powder inlet 5 (in a sealed state during processing); below the powder material outlet of the powder material box body 6 A powder closed storage box 9 is provided, and a quantitative delivery mechanism is provided between the powder material outlet of the powder material box body 6 and the powder closed storage box 9;

[0032] The surrounding side walls of the powder sealing storage box 9 are enclosed, and the lower opening forms a back-shaped structure, and two powder coating scrapers 11 are respectively install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com