Accurate-positioning injection mould with self-lubricating guiding column

A guide column and fine positioning technology, which is applied in the field of parts for mold blanks, can solve the problems of lower product yield, easy wear, and poor movement, so as to prolong the service life, improve hardness and wear resistance, and have a simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing.

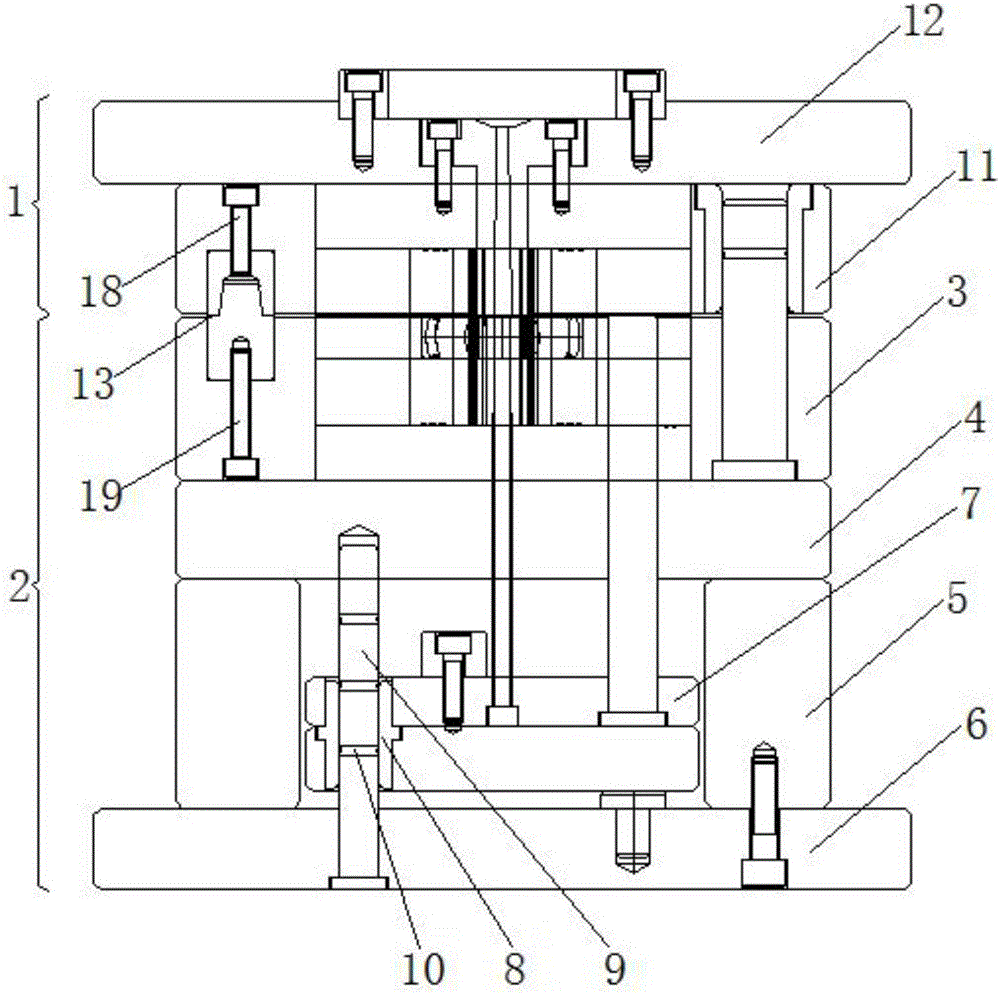

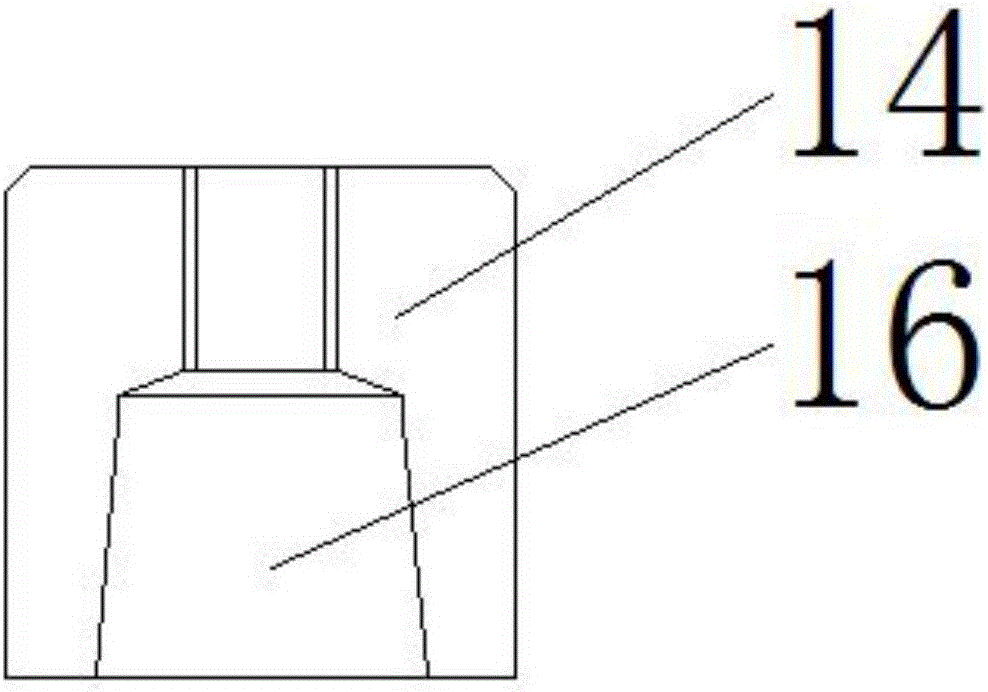

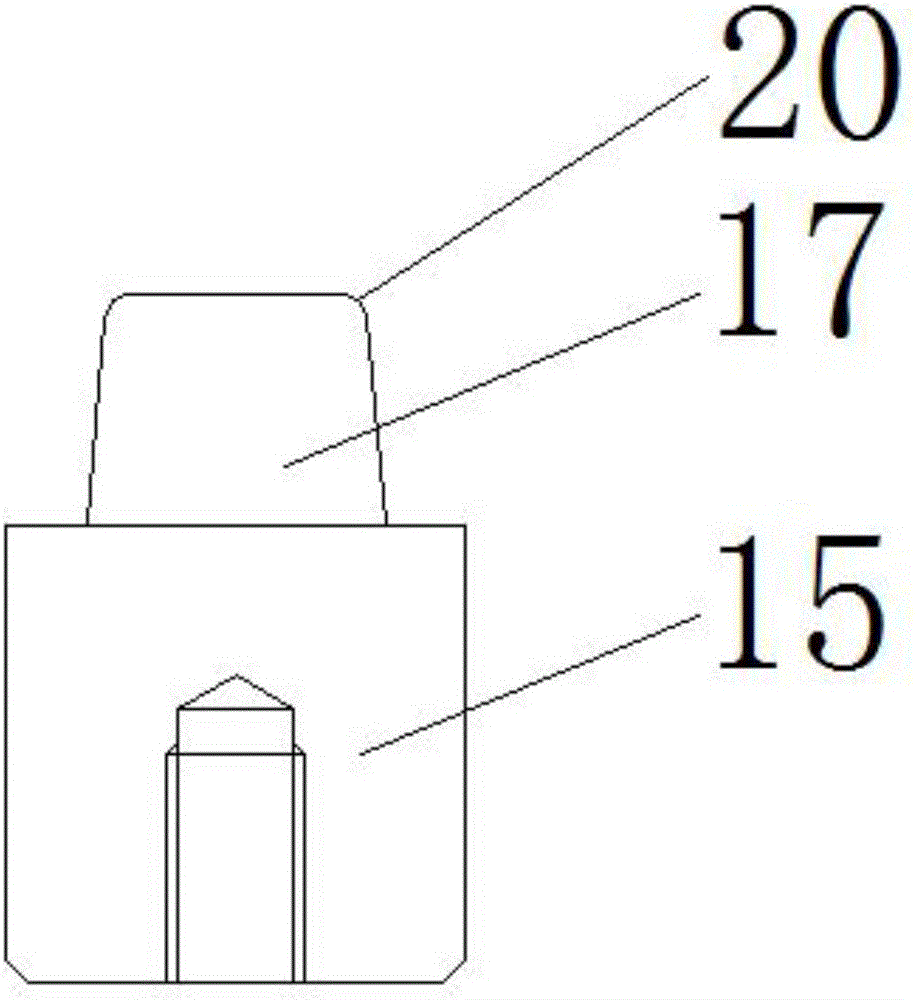

[0019] The fine positioning of the present invention and the injection mold with self-lubricating guide posts, as attached Figure 1-3 As shown, it includes a front mold 1 and a rear mold 2; the front mold 1 includes a front template 11 and a front mold fixing plate 12; the rear mold 3 includes a rear template 3, a rear mold fixing plate 4, a rear mold support 5 and Mold base 6; a thimble plate 7 is movable between the back mold fixing plate 4 and the back mold base 6; a guide sleeve 8 is fixed in the thimble plate 7; the back mold fixing plate 4 and the back mold base 6 is fixedly connected with a thimble plate guide column 9; the thimble plate guide column 9 is arranged in the guide sleeve 8; a plurality of annular grooves 10 are opened on the outer circumference of the thimble plate guide column 9; A solid lubricant is embedded in the groove 10; the solid lubricant is graphite; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com