High-precision molding machine for molding medical ultrathin blowpipe

A molding machine, high-precision technology, applied in applications, household appliances, tubular items, etc., can solve the problems of unsuitable precision medical bellows, mold and rail collision, increase maintenance costs, etc., to save raw materials and reduce camber resistance. , the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

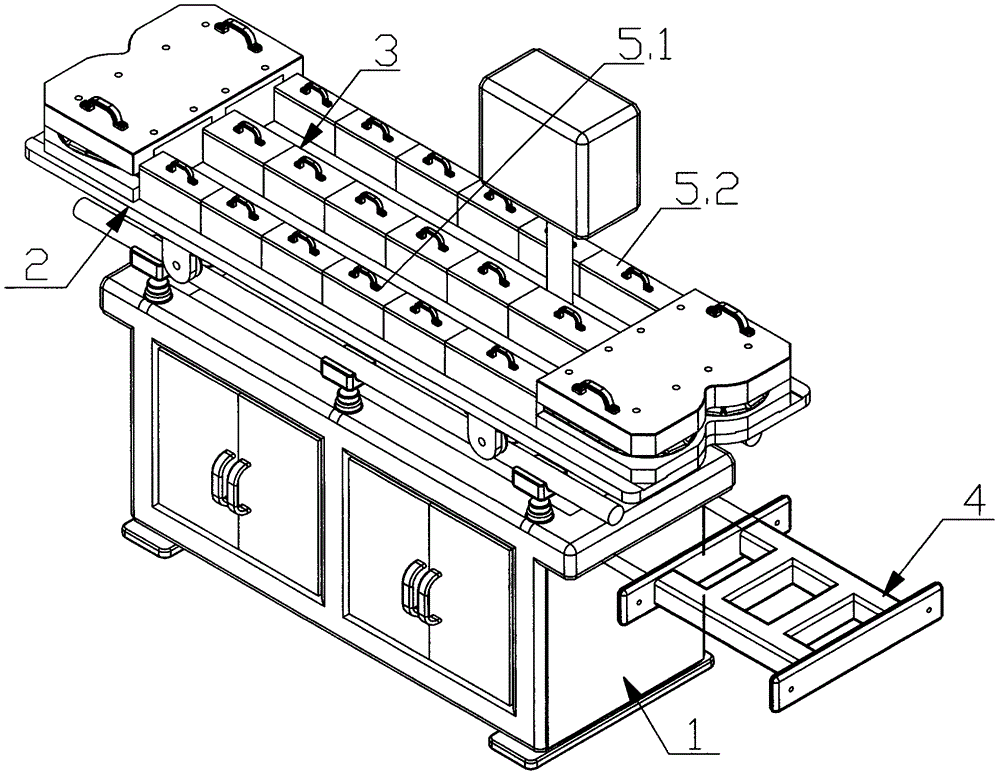

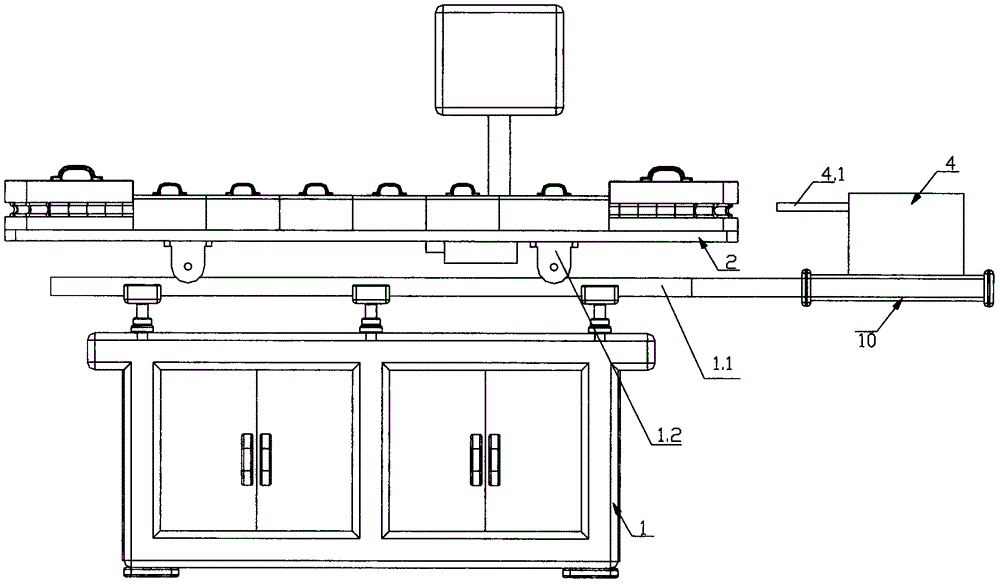

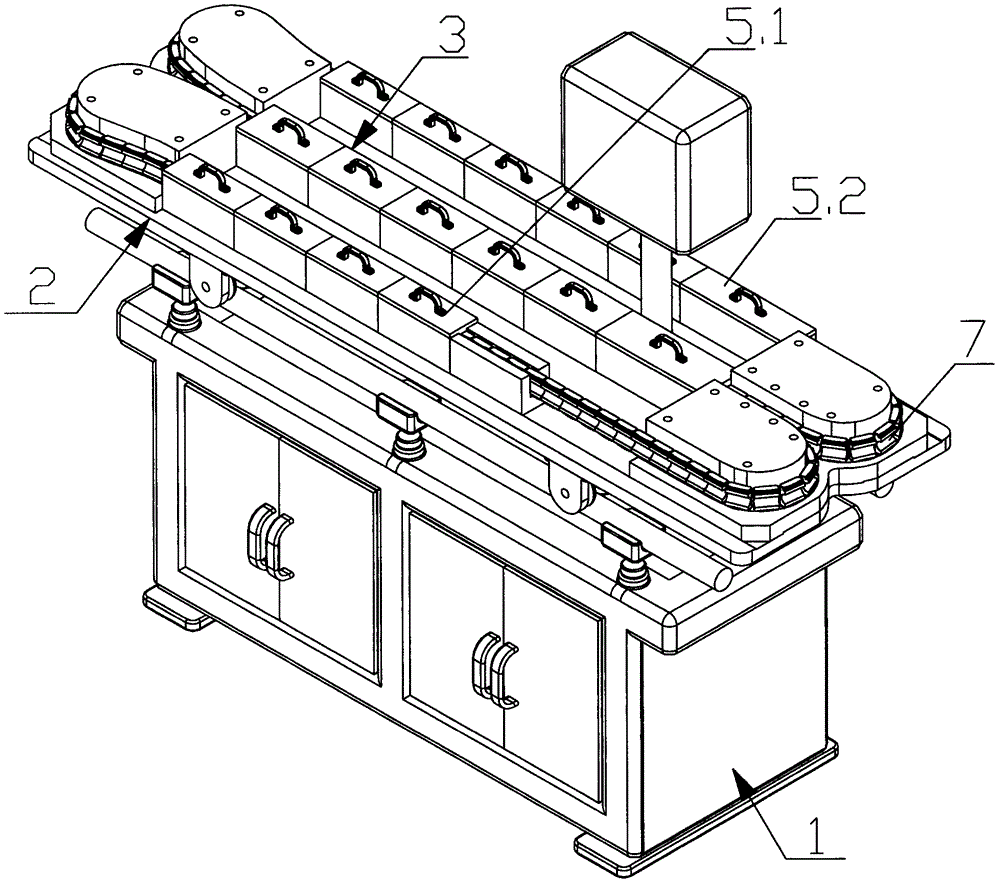

[0024] refer to Figure 1-Figure 7 Shown is a high-precision molding machine for forming medical ultra-thin blowpipes, including a base 1 and a support platform 2, the support platform 2 is located above the base 1, and the support platform 2 is provided with a tube body forming assembly 3 and a power Assemblies, the front end of the tube body forming component 3 is provided with a blow molding device host 4, and the host die head 4.1 of the blow molding device host 4 is placed in the front end of the tube body forming component 3; the tube body forming component 3 includes a guide rail component 5 1. A plurality of molds 6 for forming the shape of the pipe body and assembled in the guide rail assembly 5 , the power assembly drives the mold 6 to circulate in the guide rail assembly 5 .

[0025] The guide rail assembly 5 includes a first closed guide rail 5.1 and a second closed guide rail 5.2 placed in a mirror image, and the first closed guide rail 5.1 includes a first front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com