Production method of high-tear-strength printed crepe and printed crepe

A production method and technology of crepe cloth, which are applied in the production method of high tear strength printed crepe cloth and the field of printed crepe cloth, can solve the problems of low tear strength of printed crepe cloth, improve the serious drop of tear strength, improve tear resistance, The effect of balancing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1~5

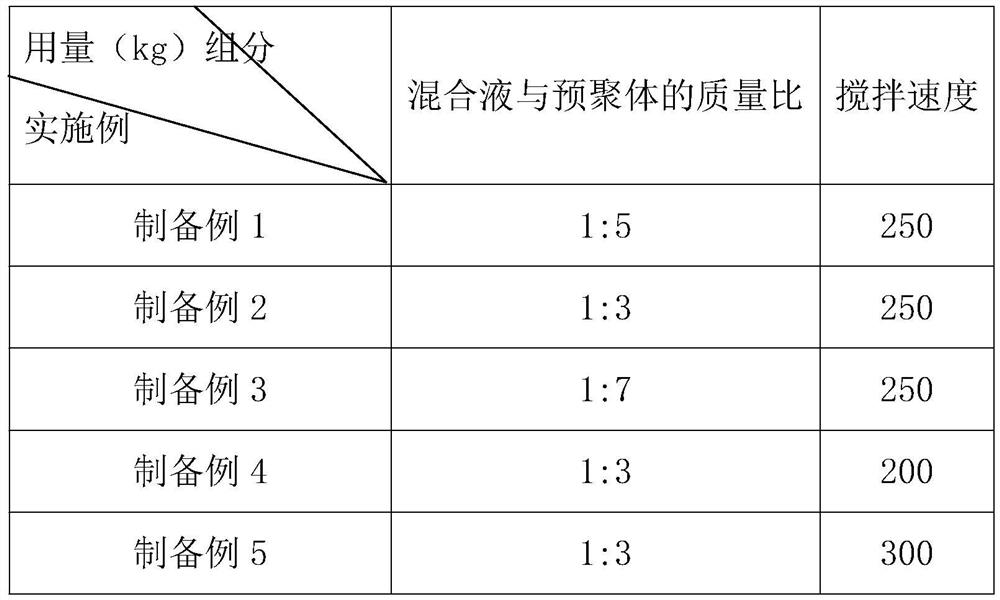

[0041] As shown in Table 1, the main difference of Preparation Examples 1-3 lies in the mass ratio of the mixed solution to the prepolymer; the main difference of Preparation Examples 1, 4, and 5 lies in the different stirring speeds.

[0042] Taking Preparation Example 1 as an example below,

[0043] The preparation method of microcapsules:

[0044] Preparation of oil phase solvent: Weigh 20g of simethicone in container A, stir evenly, and set aside;

[0045] Preparation of aqueous phase emulsion: weigh 9g of epoxy resin in container B, add epoxy resin curing agent 593, the mass ratio of epoxy resin to epoxy resin curing agent 593 is 4:1, stir and mix evenly, and pre-cure for 5 minutes , to obtain a prepolymer; add 20ml carbon tetrachloride and 3ml sorbitan oleate to the prepolymer, stir well; then add the mixed solution of ethylenediamine and alkali-resistant penetrating agent TF-107B, The mass ratio of the liquid to the prepolymer is 1:5, and it is stirred evenly at a spe...

Embodiment 1~4

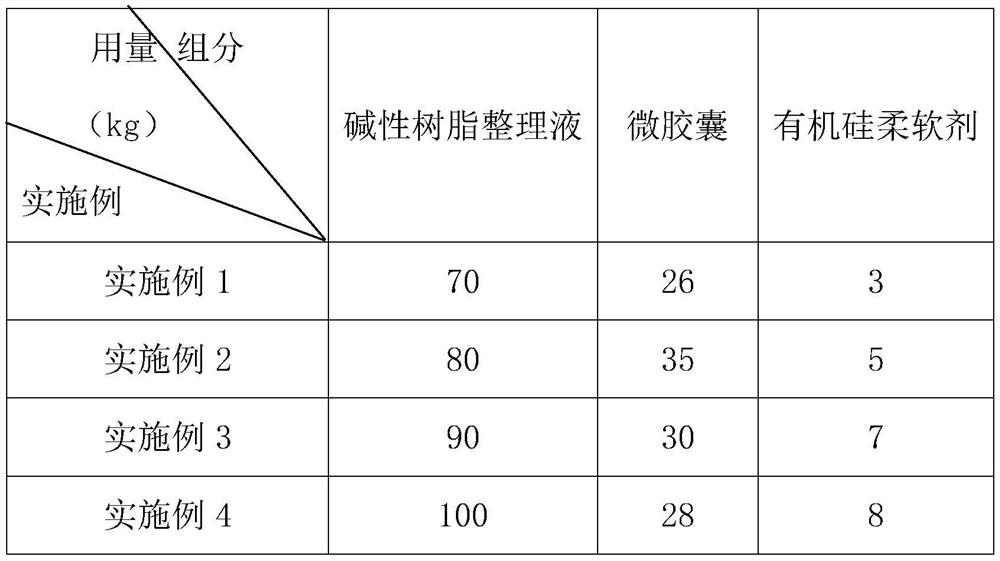

[0051] As shown in Table 2, the main difference of Examples 1-4 is that the proportioning of raw materials is different.

[0052] The following is described by taking Example 1 as an example, wherein the microcapsules prepared in Preparation Example 1 are used. Silicone softener was purchased from Dongguan Jiahong Silicone Technology Co., Ltd. The amine swelling agent is ethylenediamine, and the alkali-resistant penetrating agent is alkali-resistant penetrating agent TF-107B. The primary product of printed crepe is to first use all cotton yarns to form strands, and then weave the strands into gray fabrics. The twist of the entire cotton yarns is 180 twists / m.

[0053] The production method of the high tear strength printed crepe that embodiment 1 provides specifically comprises the following steps:

[0054] Padding: padding the primary printed crepe cloth in the anti-wrinkle finishing solution, two dipping and two rolling, the liquid retention rate is controlled above 90%, a...

Embodiment 5

[0060] Embodiment 5, the difference between this embodiment and embodiment 3 is:

[0061] The mass ratio of amine swelling agent to alkali-resistant penetrating agent is 2.5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com