Lifting lug cable clamp

A technology of cable clips and lifting lugs, applied in special structures, building components, etc., can solve the problems of increased weight, increased size of cable clips, and short life, and achieve the effects of prolonging life, avoiding bending moments, and reducing bending-resistant structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Exemplary embodiments of the present invention are described below in conjunction with the accompanying drawings, which include various details of the embodiments of the present invention to facilitate understanding, and they should be regarded as exemplary only. Accordingly, those of ordinary skill in the art will recognize that various changes and modifications of the embodiments described herein can be made without departing from the scope and spirit of the invention. Also, descriptions of well-known functions and constructions are omitted in the following description for clarity and conciseness.

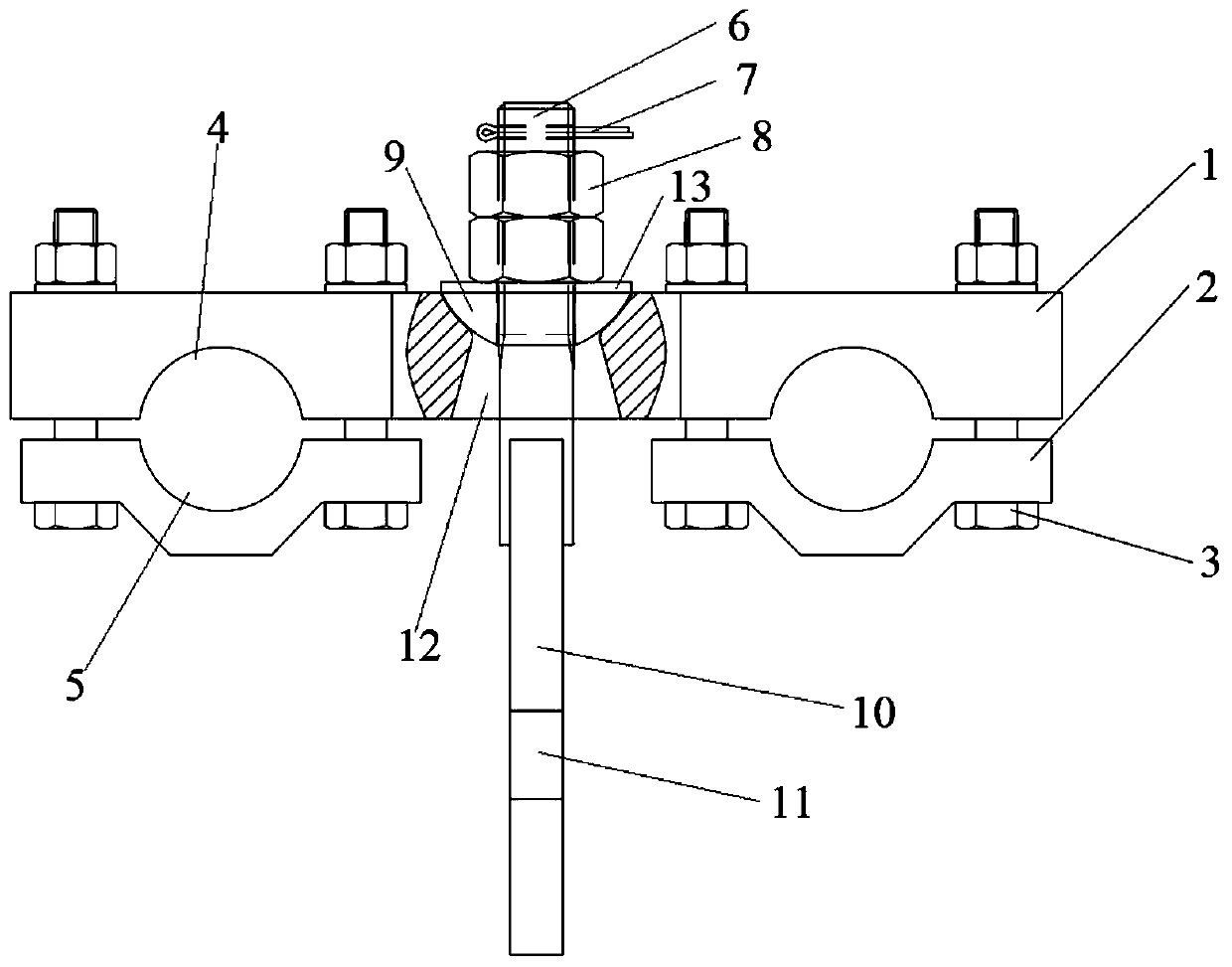

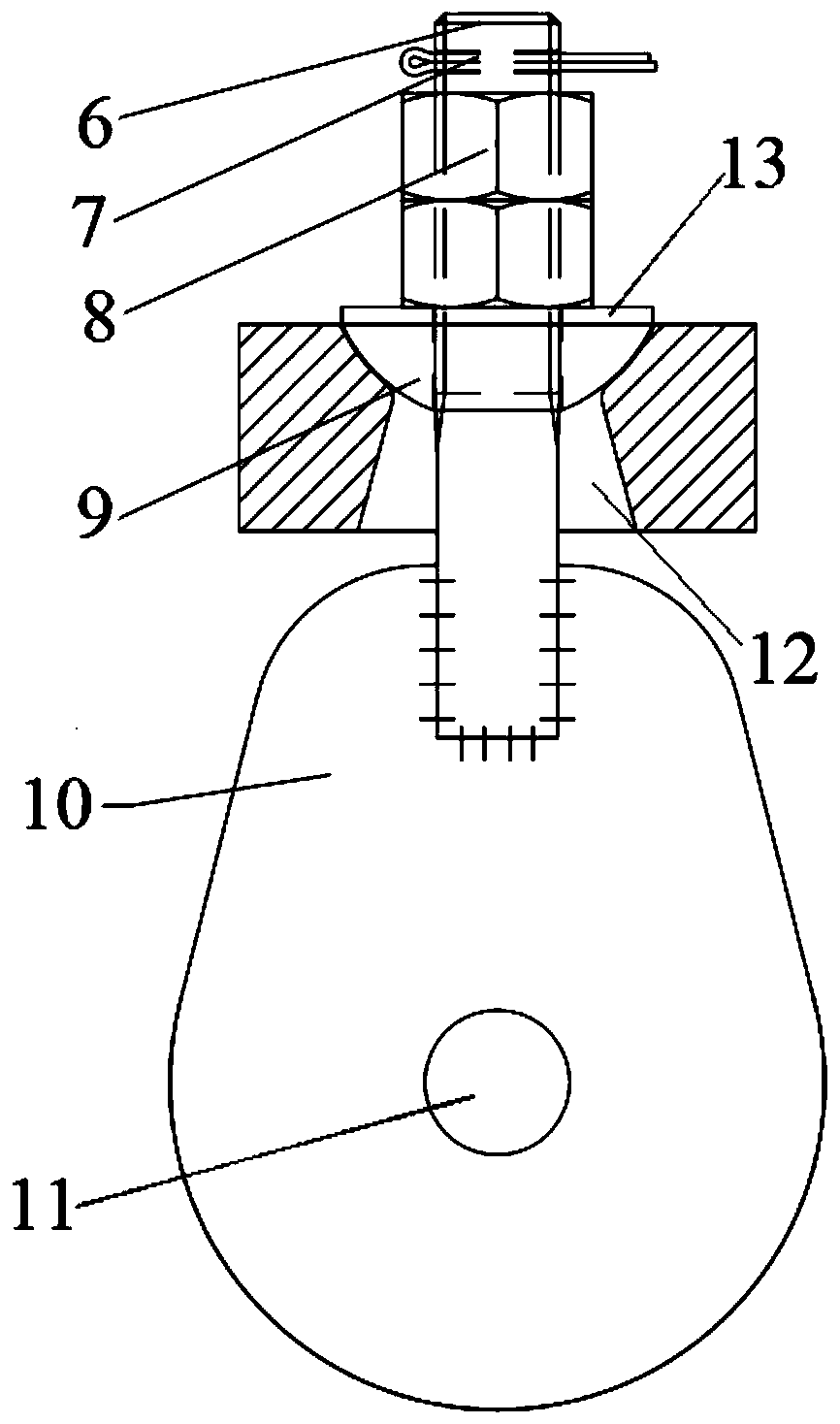

[0023] In this article, the terms "up" and "down" that indicate relative positional relationship are based on figure 1 and figure 2 point of view.

[0024] The lug clip of the present invention includes a main body mechanism, a connecting mechanism and a movable mechanism, wherein the main mechanism is provided with a through hole, and the connecting mechanism passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com