Bucketless water purifier control system

A technology of control system and pure water machine, which is applied in the direction of control/manipulation system, water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as needing to wait, not conforming to user habits, and not being able to set as required. To achieve a wide range of water quality adaptation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

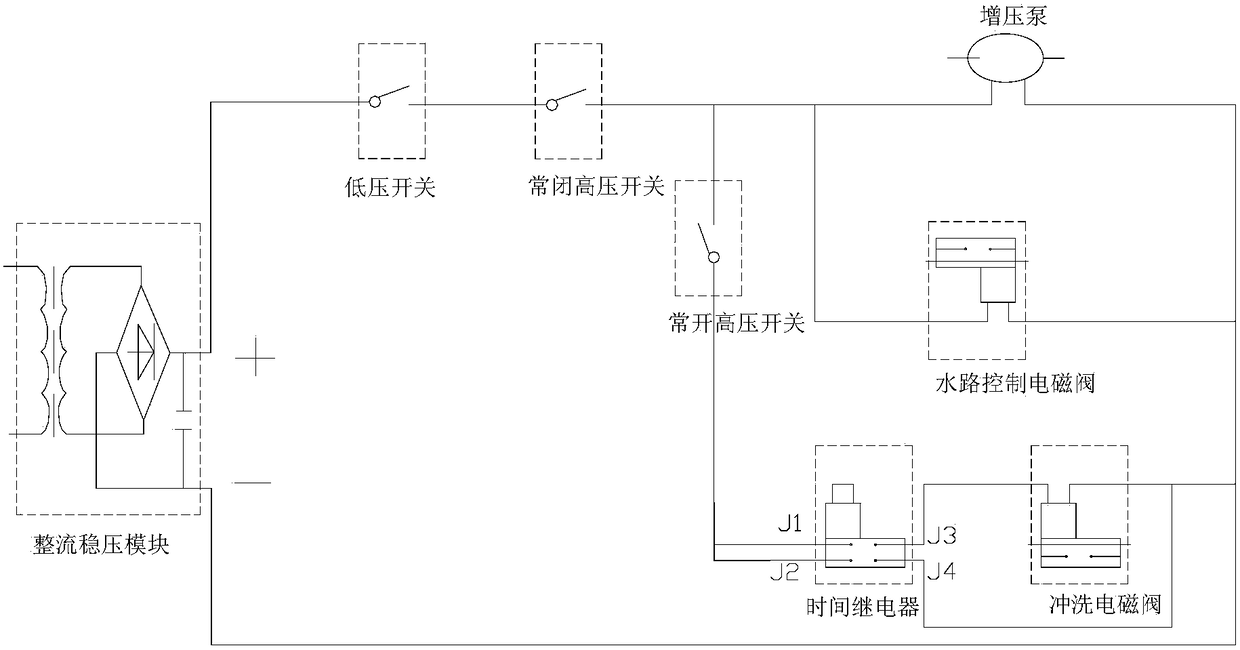

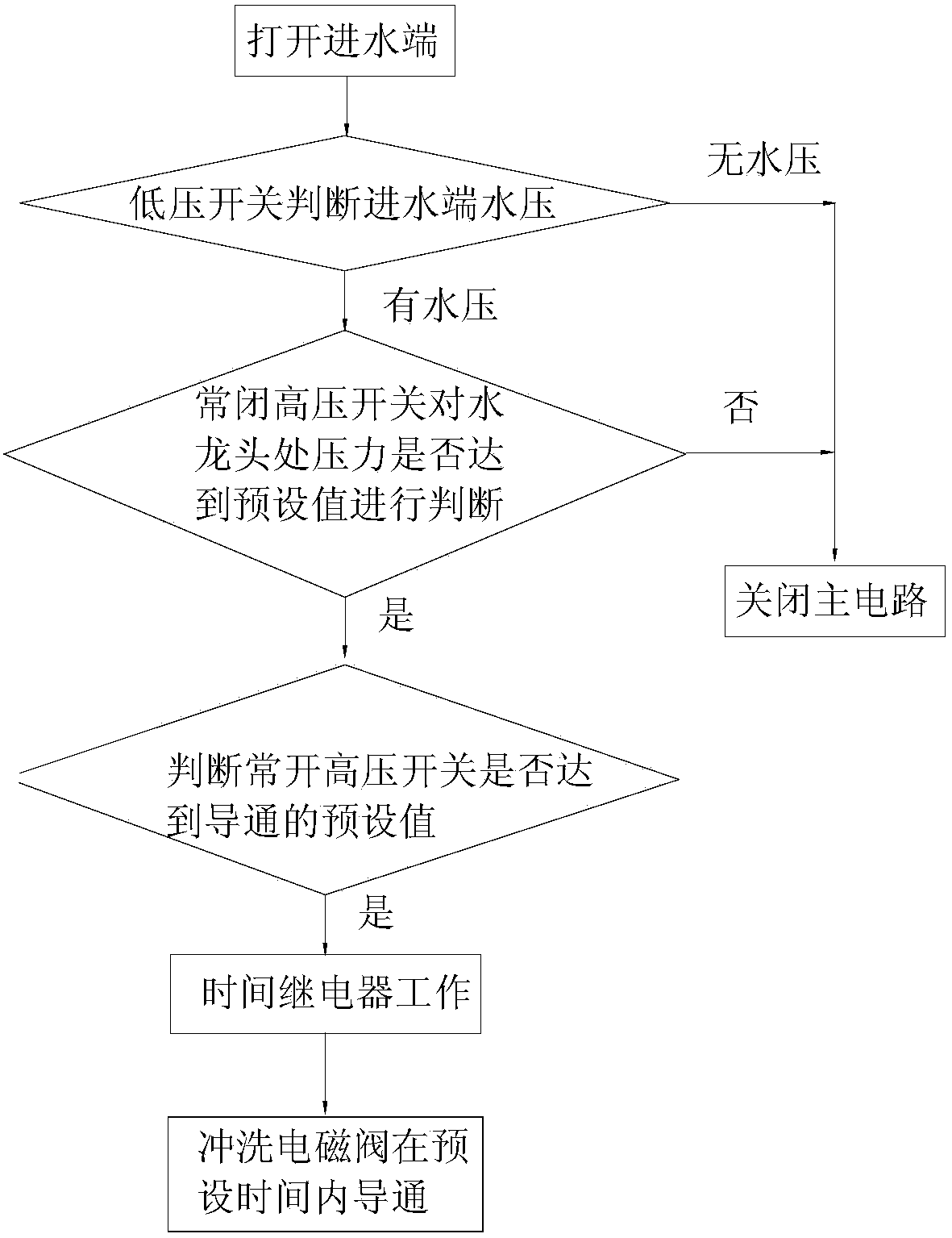

[0016] Such as figure 1 As shown, the bucket-less pure water machine control system of the present invention includes a rectification and voltage stabilization module, and the positive output terminal of the rectification and voltage stabilization module is connected with a low-voltage switch, a normally closed high-pressure switch and a booster pump in sequence; it also includes a waterway control solenoid valve and The flushing solenoid valve, the waterway control solenoid valve is connected in parallel with the booster pump; it also includes a time relay and a normally open high-voltage switch, and the time relay includes four ports J1~J4, of which J1 and J2 are input t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com