3D printing system incorporating solid build inks containing colorants

A printing system and ink technology used in 3D printing. field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

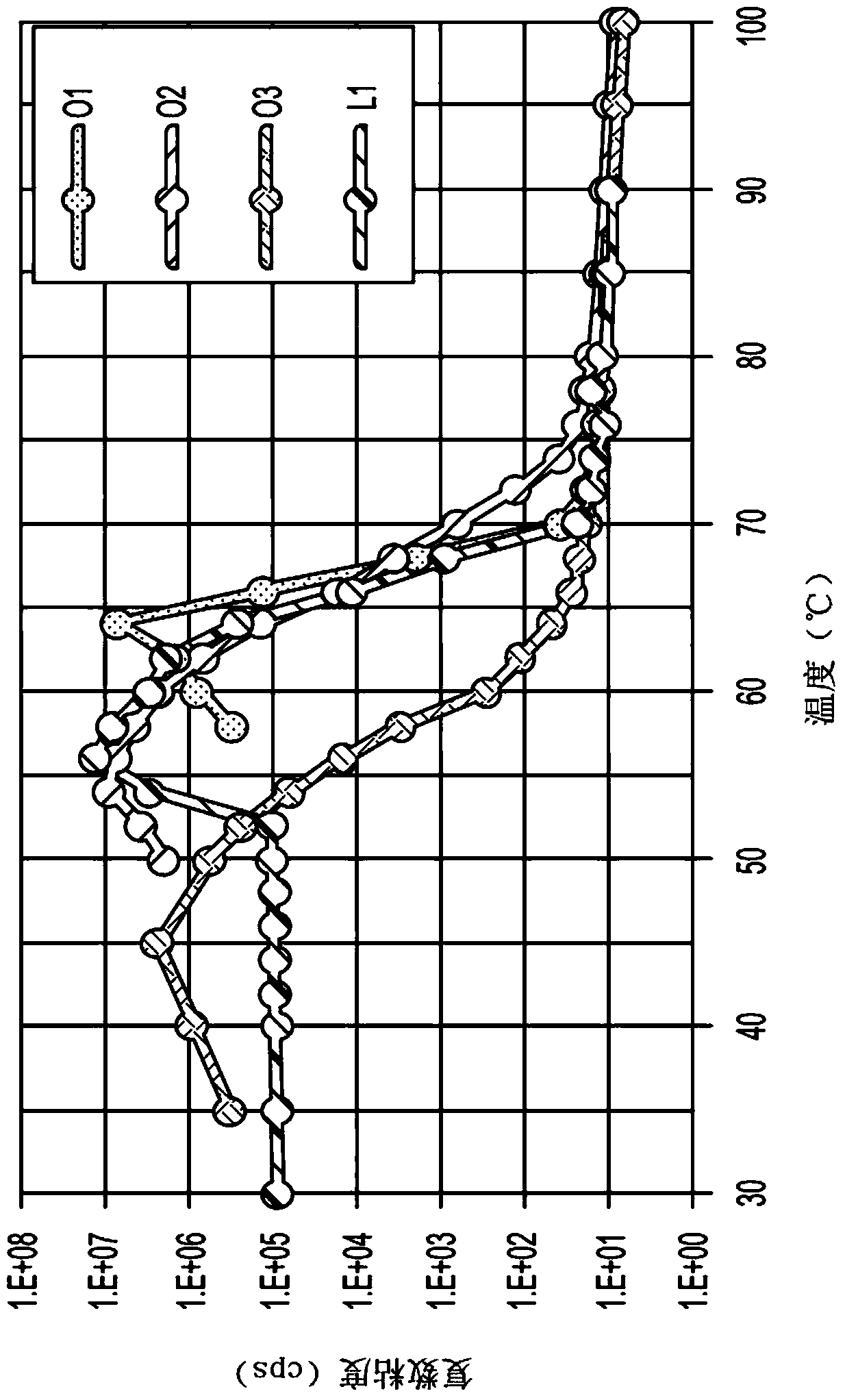

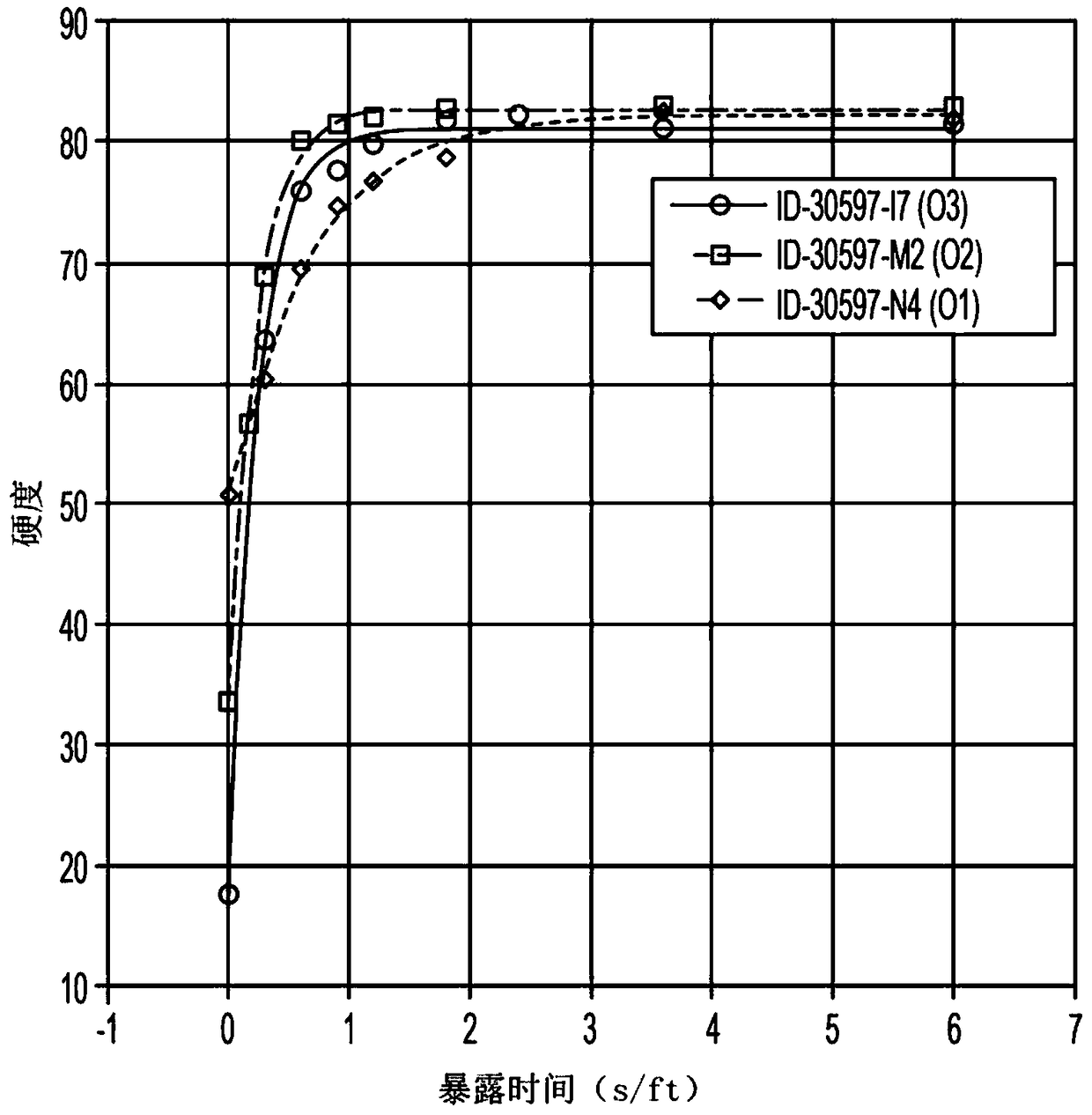

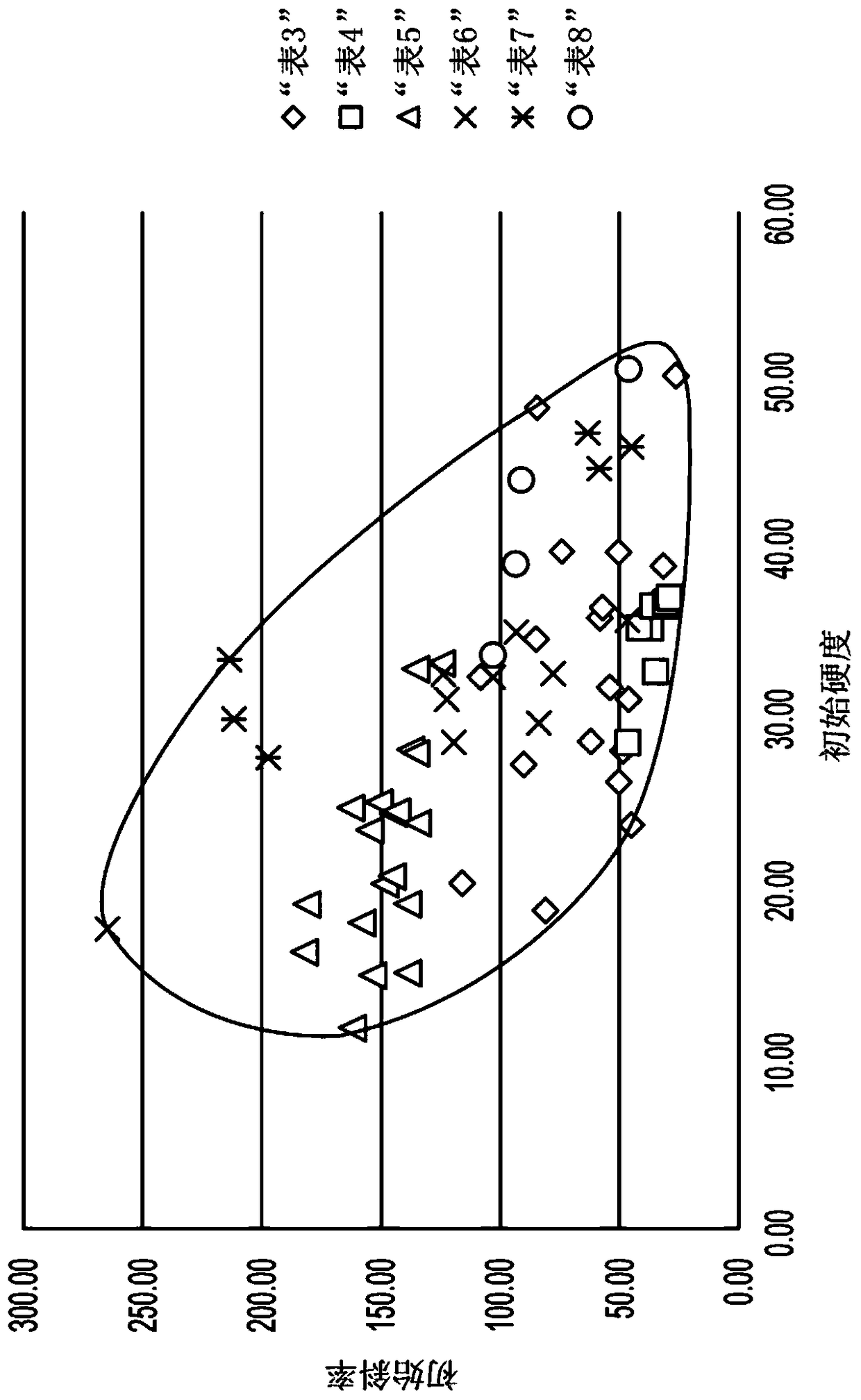

[0121] This example describes the formation of an exemplary solid structuring ink and the characterization of some of its physical properties.

[0122] A dye-based ink formulation was prepared as follows: To a 30 mL amber glass bottle was added 2.019 g CD406, 1.007 g SR368, 2.843 g CD587 (all from Sartomer Company Inc.), 0.825 g Unilin 350 Acrylate (Acrylate Curable Monofunctional Acrylic Ester wax C22, C23, C24 mixture, melting point between 50 and 60 ° C), 2.528 g Licowax KFO (an ester wax, available from Clariant), 0.155 g Irgacure 819, 0.224 g Irgacure 184 and 0.100 g Irgacure 907 ( Both are available from Ciba Specialty Chemicals). A stir bar was added to this mixture and the mixture was placed in a Variomag reaction block. The ink mixture was heated and stirred separately at 90°C and 300 RPM for at least 20 minutes or until the mixture appeared homogeneous. The temperature was increased to 100°C, held for five minutes, and then 0.300 g of BlueOlefin dye was added. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com