Double-side-coated release film

A technology of double-sided coating and release film, which is applied in coating and other directions, can solve the problems of release film adhesion and difficult separation, and achieve strong antistatic ability, wide application range and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

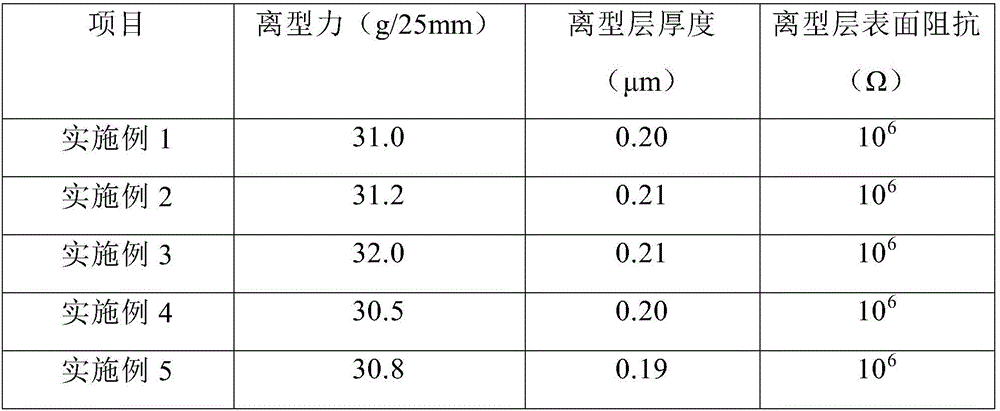

Examples

Embodiment 1

[0018] A double-sided coated release film, comprising a base film layer, both sides of the base film layer are provided with a release layer, the release layer is coated with a release agent, and the release agent contains Each component of the following mass parts: vinyl silicone resin: 10 parts; polyethylene terephthalate: 15 parts; polyethylene glycol: 6 parts; nano silicon dioxide: 3 parts; Material: 3 parts; Low surface tension additive: 0.1 part; Toughening agent: 1 part; Defoamer: 0.5 part; Solvent: 18 parts.

[0019] Wherein, the material of the base film layer is PE, the particle size of the nano silicon dioxide is 20nm, the conductive polymer is polyacetylene, and the low surface tension additive is polysiloxane polyether copolymer; The toughening agent is polybutadiene rubber; the defoamer is ethylene glycol distearate.

Embodiment 2

[0021] A double-sided coated release film, comprising a base film layer, both sides of the base film layer are provided with a release layer, the release layer is coated with a release agent, and the release agent contains Each component of the following mass parts: vinyl silicone resin: 12 parts; polyethylene terephthalate: 18 parts; polyethylene glycol: 5 parts; nano silicon dioxide: 1 part; Substance: 5 parts; Low surface tension additive: 0.3 parts; Toughening agent: 1.5 parts; Defoamer: 1 part; Solvent: 20 parts.

[0022] Wherein, the material of the base film layer is PMMA, the particle diameter of the nano silicon dioxide is 50nm, the conductive polymer is polyacetylene, and the low surface tension additive is polysiloxane polyether copolymer; The toughening agent is polybutadiene rubber; the defoamer is polyoxypropylene polyoxyethylene glyceryl ether.

Embodiment 3

[0024] A double-sided coated release film, comprising a base film layer, both sides of the base film layer are provided with a release layer, the release layer is coated with a release agent, and the release agent contains Each component of the following mass parts: vinyl silicone resin: 17 parts; polyethylene terephthalate: 23 parts; polyethylene glycol: 6 parts; nano silicon dioxide: 5.5 parts; Substance: 6 parts; Low surface tension additive: 0.5 parts; Toughening agent: 2.3 parts; Defoamer: 1.1 parts; Solvent: 23 parts.

[0025] Wherein, the material of the base film layer is PET, the particle size of the nano silicon dioxide is 40nm, the conductive polymer is polypyrrole, and the low surface tension additive is polysiloxane polyether copolymer; The toughening agent is nitrile rubber; the defoamer is ethylene glycol distearate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap