A valley-type tailings pond flood drainage system

A technology for tailings ponds and valleys, applied in the field of tailings ponds, can solve problems such as incompatibility and environmental pollution, and achieve the effects of saving investment, reducing costs, and facilitating collection and diversion of backwater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

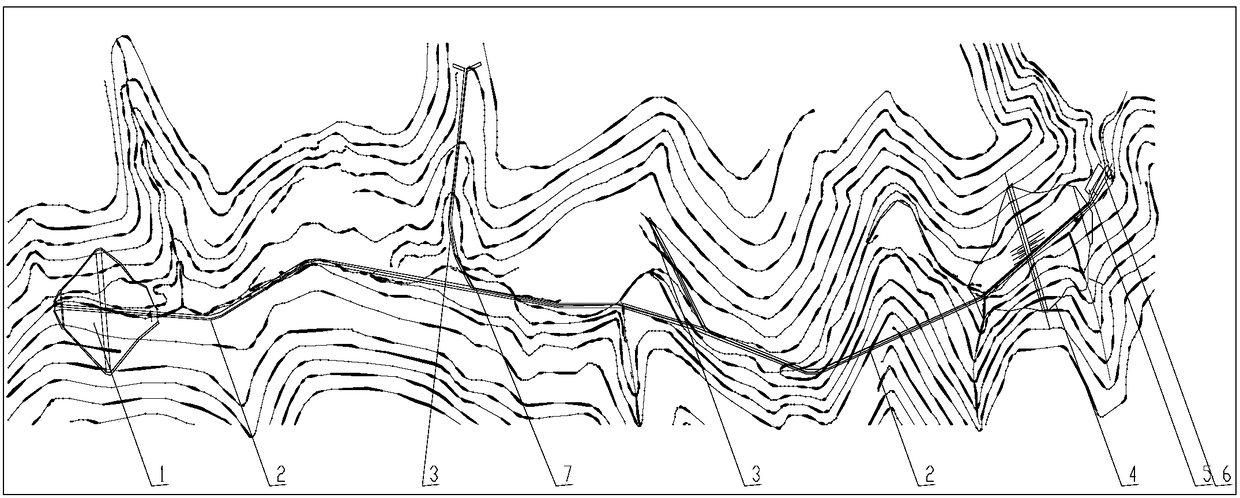

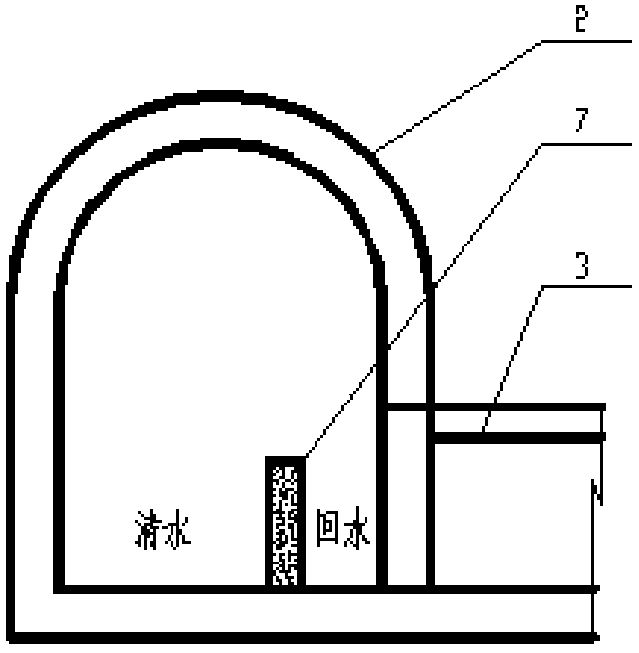

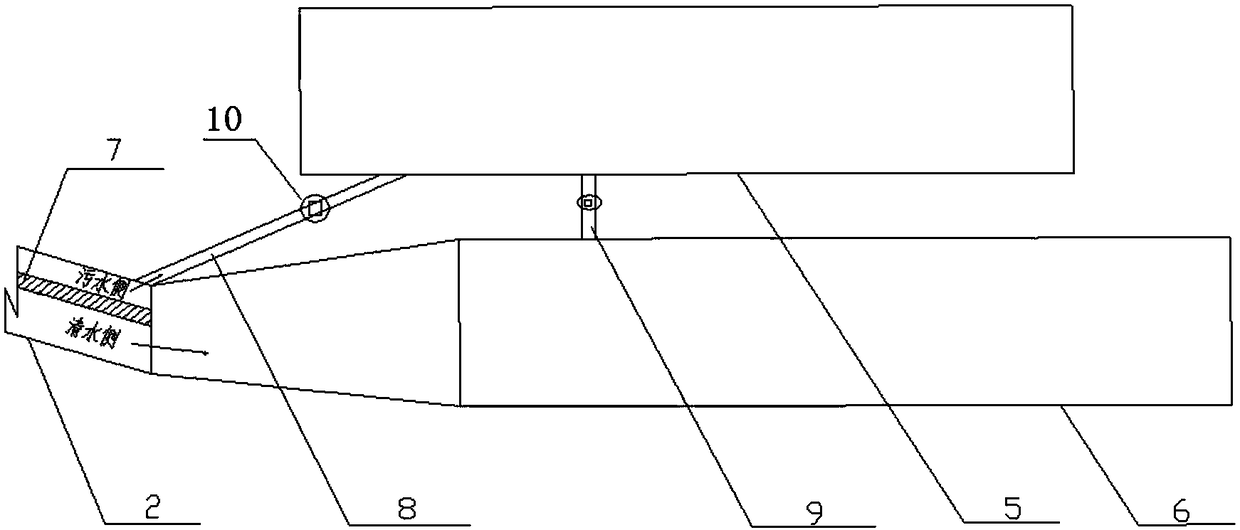

[0022] see figure 1 , the system provided by the present invention includes: an initial dam 4 arranged downstream of the tailings dam and a flood dam 1 arranged upstream of the initial dam 4, and a return pool 5 for collecting backwater from the tailings dam is arranged downstream of the initial dam 4 and a stilling pool 6; between the initial dam 4 and the flood dam 1, a main flood discharge tunnel 2 is arranged along one side of the valley; the main flood discharge tunnel 2 is provided with a retaining wall 7, and the retaining wall 7 will mainly The flood discharge tunnel 2 is divided into a clear water side and a sewage side. The upstream of the clear water side of the main flood discharge tunnel 2 is connected to the flood dam 1 , the downstream is connected to the stilling tank 6 , and the sewage side is connected to the backwater tank 5 . The sewage s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com