Integrated flood discharging system for tailing pond flood-sewage diversion and ore pulp conveying

A technology of tailings storage and slurry, which is applied in the field of tailings storage, and can solve problems such as poor separation of engineering floods and sewage, and difficulties in the maintenance of tailings transportation pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

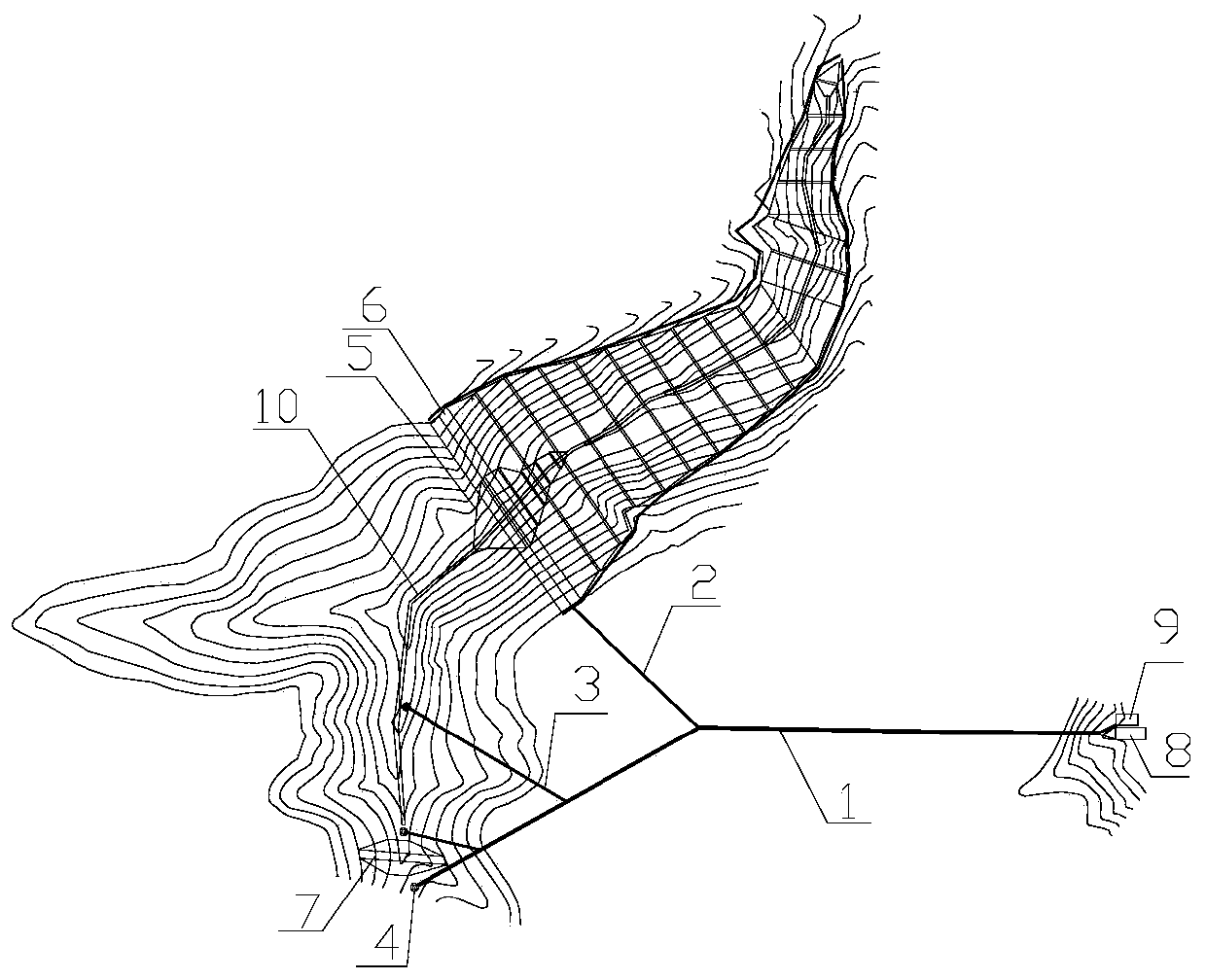

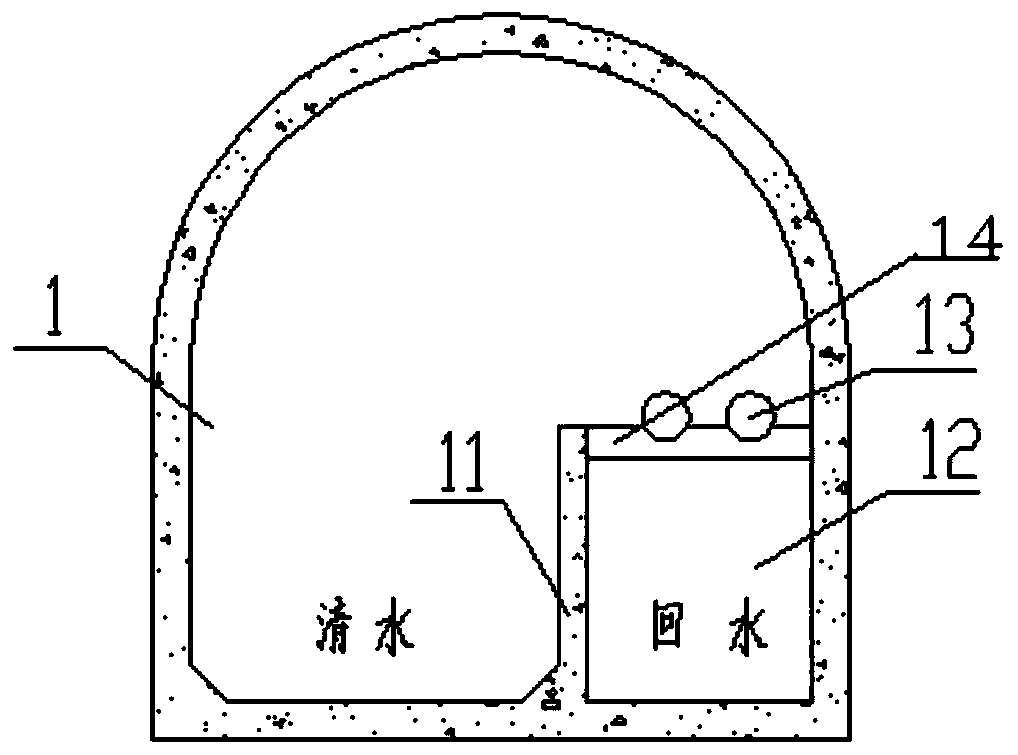

[0024] An integrated flood drainage system for flood and sewage diversion and slurry transportation in tailings ponds, including a main flood drainage tunnel, the upstream side of the main flood drainage tunnel is respectively connected with a flood drainage branch tunnel and a tailings conveying branch tunnel, and the main flood drainage tunnel along the drainage A water partition wall is set along the length of the main flood tunnel, and the water wall and the side wall of the main flood discharge tunnel form a return channel. The return channel is arranged along the length direction of the main flood discharge tunnel and the branch tunnels. A cover plate is set above the inner return channel between the top of the water partition wall and the main flood discharge tunnel, and a tailings conveying pipeline is arranged on the cover plate, and the tailings conveying pipeline is arranged along the length direction of the main flood discharge tunnel and the tailings conveying branc...

Embodiment 2

[0026] On the basis of Embodiment 1, the flood discharge branch tunnel is also communicated with an overflow well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com