Veneer back face grooving method

A slotting method and decorative panel technology, which is applied in the direction of construction and building construction, can solve the problems of fire hazards, high cost of steel keel production, and tile falling off, so as to achieve standardized operations, reduce the risk of damage, and improve construction. speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the drawings.

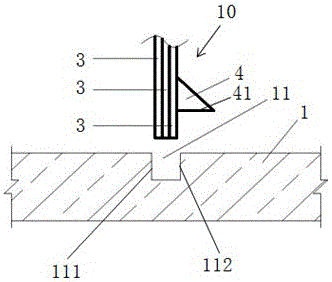

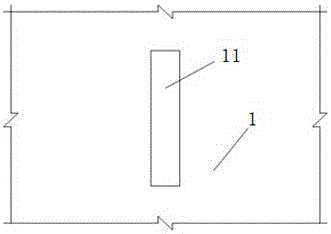

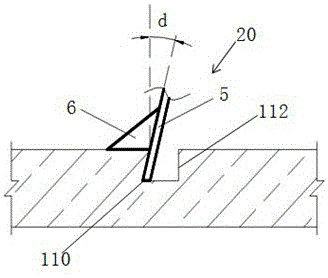

[0021] Such as Figure 1 to Figure 6 As shown, the method for grooving the back of the veneer panel of this embodiment includes the following steps: 1) mark the position of the groove on the back of the veneer 1 according to the design drawings; 2) design the depth of the trapezoidal groove according to the thickness of the veneer 1, The depth of the trapezoidal groove is less than the thickness of the veneer, so that the bottom surface of the groove after the slot has a certain protective thickness to the smooth surface of the veneer, so that the veneer has a certain strength at the slot position. The specific data can be based on different veneer materials Obtained through experimental tests; 3) Use the slotting device 10 to make a U-shaped groove 11 at the marked position on the back of the veneer 1 to make the U-shaped groove 11 reach the design depth and length; 4) Use the wideni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com