Aluminum electrolyzer electrode (variants)

An electrolytic cell and electrode technology, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of cathode weight, high brittleness, poor resistance, etc., achieve reduction of electrode weight, fire resistance and heat resistance, and improve durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

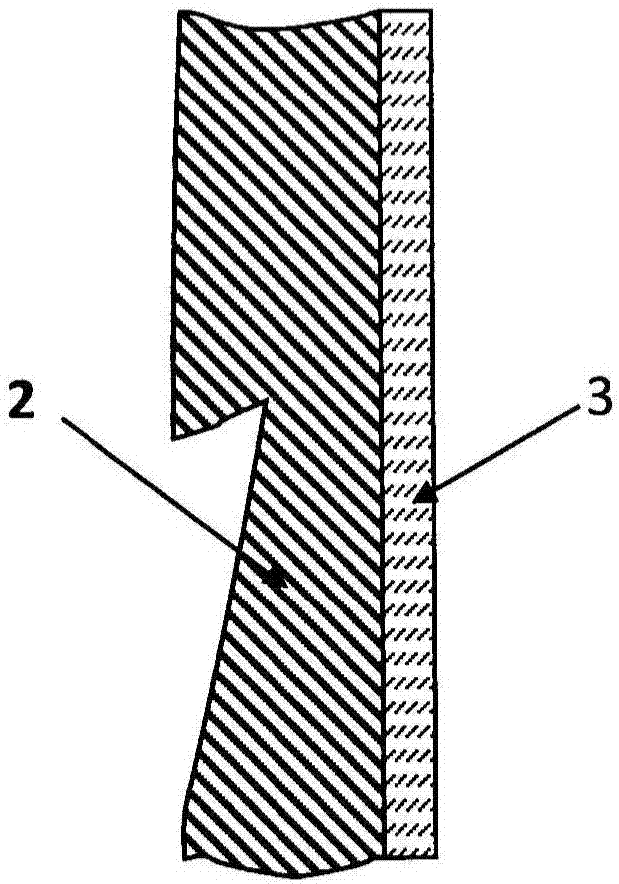

[0059] Example 1 illustrates a first embodiment of the invention. For the manufacture of aluminum wetted electrodes, 80 mass% Fe-20 mass% TiB with dimensions 94*77*10mm is used 2 A plate of composite material serves as the matrix 2 workpiece. A stainless steel rod used as a current collector was arc welded to the plate. Next, wet the surface of the workpiece with electrodes in a phenol-formaldehyde resin solution with ceramic particles TiB 2 The suspension is covered to produce a surface coating. The covered coating was dried at room temperature for 1 hour, then at 150°C for 1 hour. In this way, a surface coating 3 having a thickness of 1.5 mm and consisting of titanium diboride (93% by mass) and phenolic resin (7% by mass) was formed on the surface of the aluminum wetted electrode.

[0060] FIG. 1(A) schematically illustrates a cross-section of an electrode prepared according to Example 1.

[0061] The samples prepared by this method were tested as vertical cathodes elec...

Embodiment 2

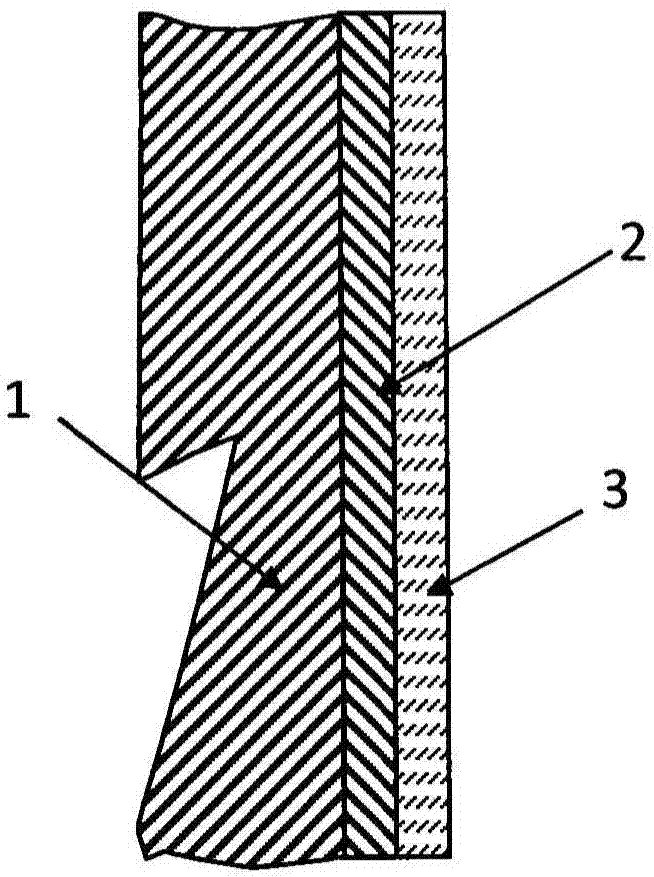

[0063] Example 2 shows a second embodiment of the present invention. For the manufacture of aluminum wetting electrodes, a metal matrix of structural steel St3 with dimensions 100*70*5 mm is used. The metal (steel) base has a shank for welding the metal current collector to it. In a first step, a nickel-iron foam plate with a thickness of 3 mm was brazed to the base body 1 to form an intermediate layer. The specific porosity of nickel-iron foam is 60PPI. In the phenol-formaldehyde resin solution, the porous metal matrix on the surface of the substrate was impregnated with ceramic particles TiB 2 suspension to produce a composite interlayer. In the next step, a layer of the suspension with a thickness of about 1 mm is applied to form a surface coating. In addition, the electrode workpiece having the surface coating applied thereon was dried at room temperature for 1 hour, and then at 150° C. for 1 hour. For coating sintering, samples were fired at 800 °C for 3 h in an acti...

Embodiment 3

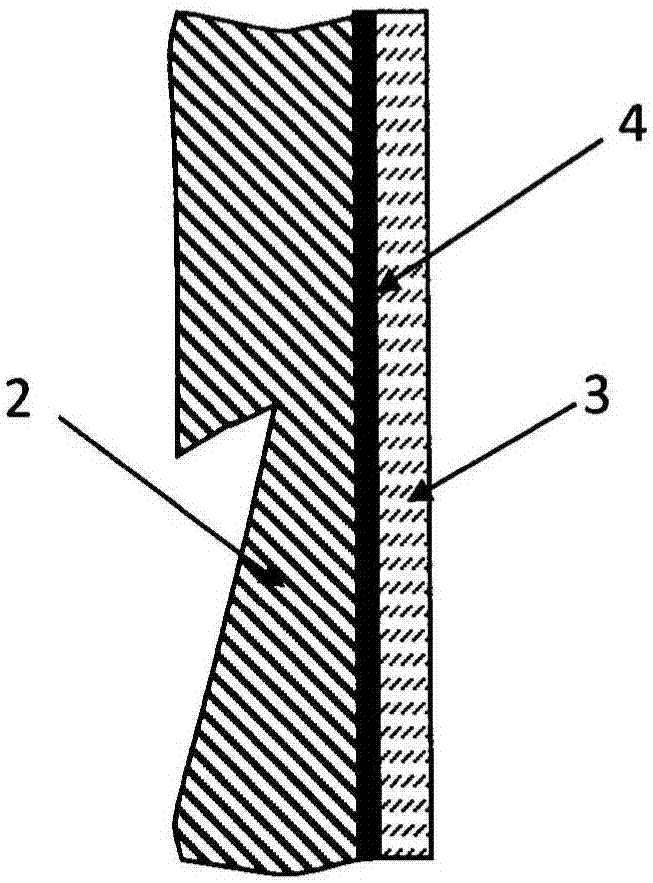

[0068] Example 3 is an illustration of a specific variant of the first embodiment according to the invention with surface carburization of a matrix of composite material. For the manufacture of aluminum wetted electrodes, 80 mass% Fe-20 mass% TiB with dimensions 96*81*10mm is used 2 The composite material plate serves as the matrix 2 workpiece. In order to saturate the surface layer 4 of the sample with carbon diffusion, the plate was solid-phase carburized. As carburizing agent, a mixture consisting of 80% charcoal and 20% sodium carbonate was used. The carburizing process lasted 10 hours in a sealed corundum container at 900°C. Then, a stainless steel rod serving as a current collector was arc welded to the composite plate. Next, wet the surface of the workpiece with electrodes in a phenol-formaldehyde resin solution with ceramic particles TiB 2 suspension coverage. The electrode base 2 was dried at room temperature for 1 hour, and then at 150° C. for 1 hour. In this w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com