Cross-linked environment-friendly flame-retardant reinforced polyamide-based composite material and preparation method thereof

A polyamide-based, composite material technology, applied in the field of polymer materials, can solve the problems of high cost of flame-retardant glass fiber reinforced nylon, flame-retardant glass fiber reinforced semi-aromatic nylon, and high requirements for flame retardants, and achieves improved weld line strength, The effect of reducing the risk of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

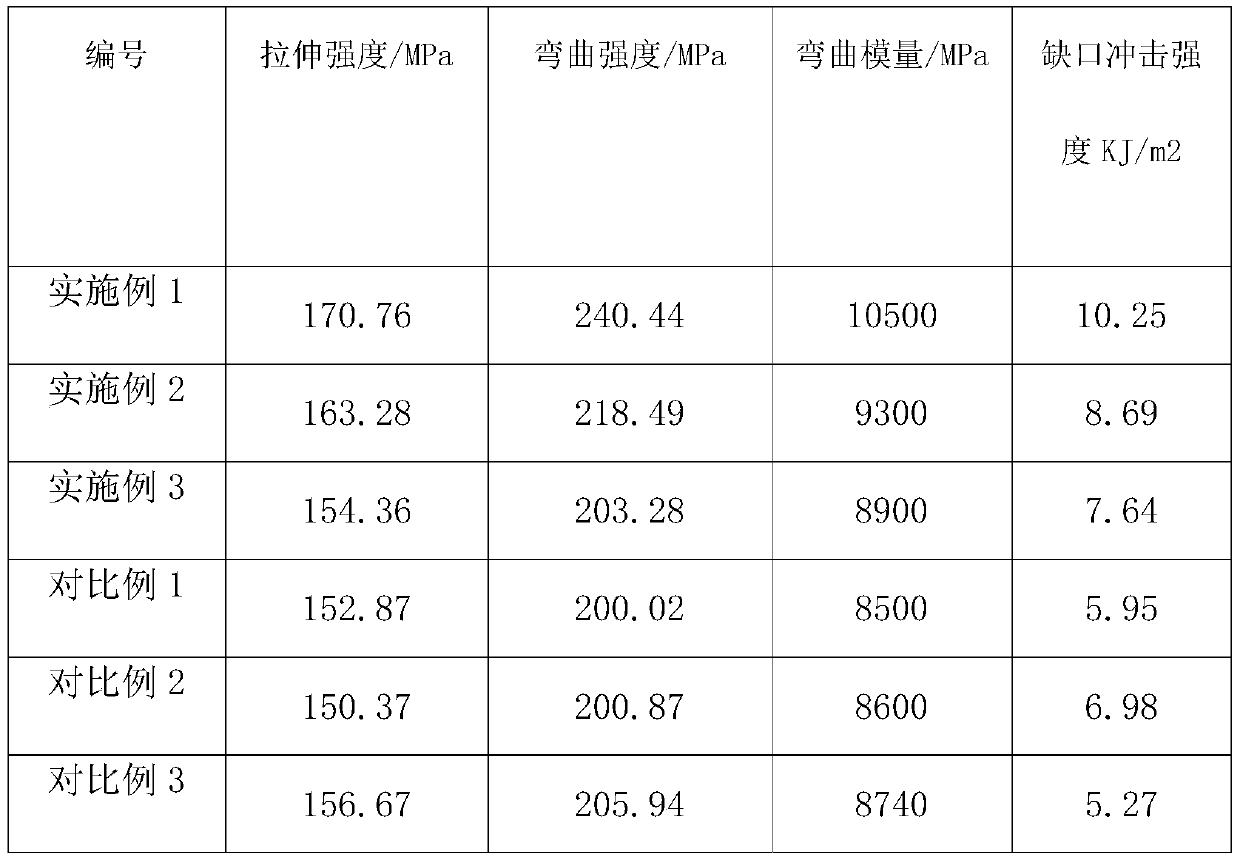

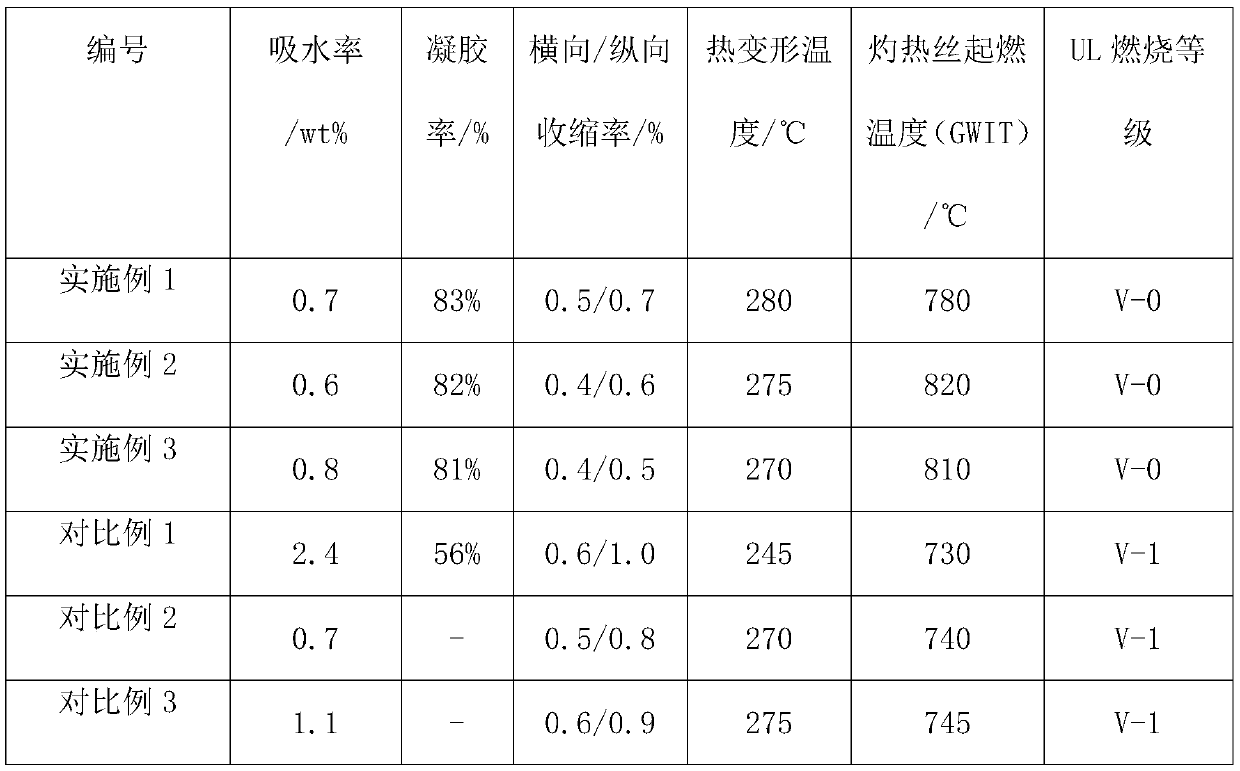

Examples

Embodiment 1

[0043] A cross-linked environment-friendly flame-retardant reinforced polyamide-based composite material, comprising: 52 parts by weight of nylon 66 (PA66), 30 parts by weight of glass fiber, 5 parts by weight of a compatibilizer (maleic anhydride graft copolymer), and a flame retardant 10 parts by weight of aluminum diethyl hypophosphite, 1 part by weight of main crosslinking agent, 1 part by weight of auxiliary crosslinking agent, 0.2 part by weight of antioxidant (model 1098), 0.5 part by weight of coupling agent (KH570), lubricant ( Silicone masterbatch) 0.3 parts by weight.

[0044] The preparation method of the above-mentioned cross-linked environmentally friendly flame-retardant reinforced polyamide-based composite material, the steps are as follows:

[0045] 1) Put the formulated amount of glass fiber and coupling agent into a high-speed mixer, set the speed at 500r / min, and stay for 5 minutes to fully mix and disperse each component.

[0046] 2) Put the formula amoun...

Embodiment 2

[0053] A cross-linked environment-friendly flame-retardant reinforced polyamide-based composite material, comprising: 47 parts by weight of nylon 66 (PA66), 30 parts by weight of glass fiber, 5 parts by weight of a compatibilizer (maleic anhydride graft copolymer), and a flame retardant 15 parts by weight of aluminum diethyl hypophosphite, 1 part by weight of main crosslinking agent, 1 part by weight of auxiliary crosslinking agent, 0.2 part by weight of antioxidant (model 1098), 0.5 part by weight of coupling agent (KH570), lubricant ( Silicone masterbatch) 0.3 parts by weight.

[0054] Its preparation method is identical with the preparation method of embodiment 1.

Embodiment 3

[0056] A cross-linked environment-friendly flame-retardant reinforced polyamide-based composite material, comprising: 47 parts by weight of nylon 66 (PA66), 30 parts by weight of glass fiber, 5 parts by weight of a compatibilizer (maleic anhydride graft copolymer), and a flame retardant 15 parts by weight of melamine cyanurate, 1 part by weight of main crosslinking agent, 1 part by weight of auxiliary crosslinking agent, 0.2 part by weight of antioxidant (model 1098), 0.5 part by weight of coupling agent (KH570), lubricant (silicon Ketone masterbatch) 0.3 parts by weight.

[0057] Its preparation method is identical with the preparation method of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com