The tunneling method of coal roadway shielding in the advance area of the directional hole in the upward penetration layer on the floor of the outburst coal seam

A technology of protruding coal seams and directional holes, applied in earthwork drilling, gas discharge, safety devices, etc., can solve the problems of restricting coal mining speed, large number of construction drilling holes, and short detection distance, so as to ensure safe and efficient operation, The effect of reducing the amount of geophysical prospecting and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

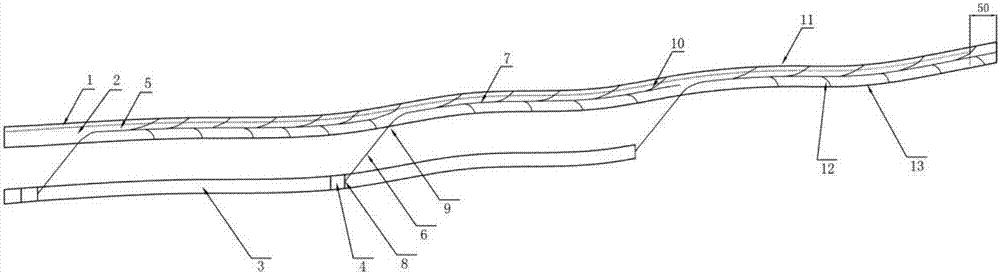

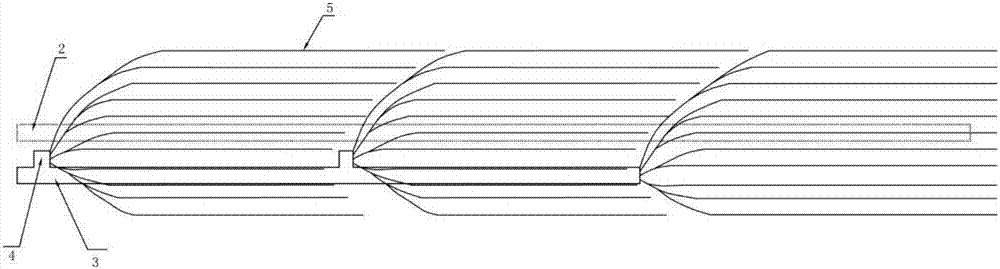

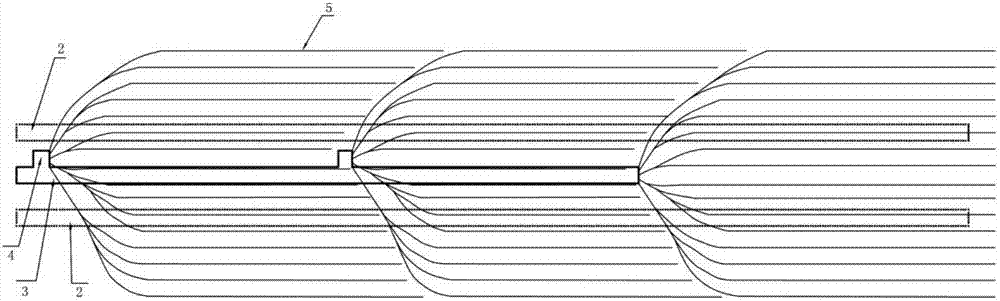

[0029] see Figure 1 to Figure 3 , showing the method for tunneling the coal roadway in the advanced area of the overhanging layer directional hole on the floor of the outburst coal seam of the present invention.

[0030] The tunneling method for protecting the coal roadway in the advanced area of the upward penetration layer directional hole on the floor of the outburst coal seam includes the following steps:

[0031] Step 1: Prepare a plurality of drilling sites 4 in the bottom roadway 3 below the side of the coal seam 1 to be excavated. Optionally, the direction of the bottom roadway 3 is the same as that of the coal roadway 2 to be excavated. In the stable coal stratum with a vertical distance of 10-20m from the bottom plate of the coal mining roadway 2, its height changes with the undulation of the coal seam 1, and the relative balance between the two is kept. The length of the bottom roadway 3 is equal to the length of the coal mining roadway 2 minus the floor plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com