Compound molecular pump using segmented structure traction level

A composite molecular pump and segmented technology, which is applied to the components of the pumping device for elastic fluids, non-variable volume pumps, non-displacement pumps, etc., can solve the problem of increased gas leakage and decreased performance of composite molecular pumps. , the increase of gap leakage, etc., to achieve the effect of improving the pumping performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

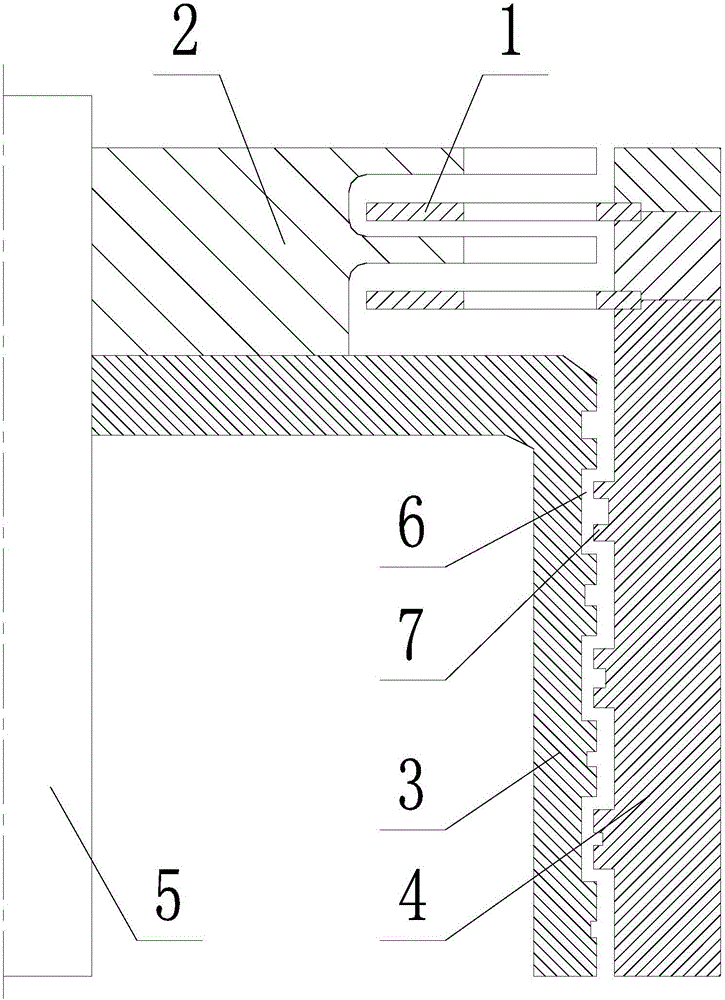

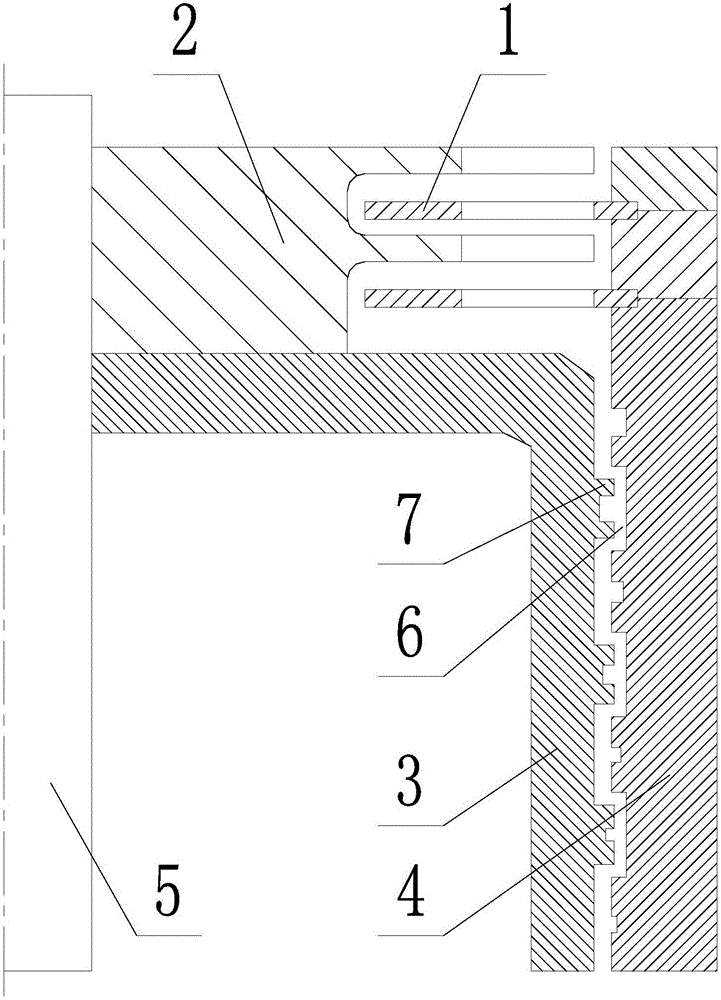

[0020] Such as figure 1 , 2 As shown, a compound molecular pump adopting a segmented traction stage includes a turbine stage, a cylindrical traction stage and a drive main shaft 5, the turbine stage includes a stator blade 1 and a moving impeller 2, and the cylindrical traction stage includes The traction rotor 3 and the stator 4, the moving impeller 2 and the traction rotor 3 are fixedly set on the driving main shaft 5, and the characteristics are: the cylindrical traction stage adopts a segmented structure, and the adjacent sections of the cylindrical traction stage An annular groove 6 and an annular boss 7 are provided, and the annular groove 6 and the annular boss 7 are arranged facing each other, and the axial centerline of the annular groove 6 and the annular boss 7 is aligned with the drive spindle The axial centerlines of 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com