Plate connecting structure and plate connecting method

A technology for connecting structures and panels, applied in the direction of connecting components, thin-plate connections, mechanical equipment, etc., can solve problems that affect product quality and aesthetics, uneven adjacent panels, reduce production costs, etc., to improve product quality, assembly The effect of easy operation and reduced process difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

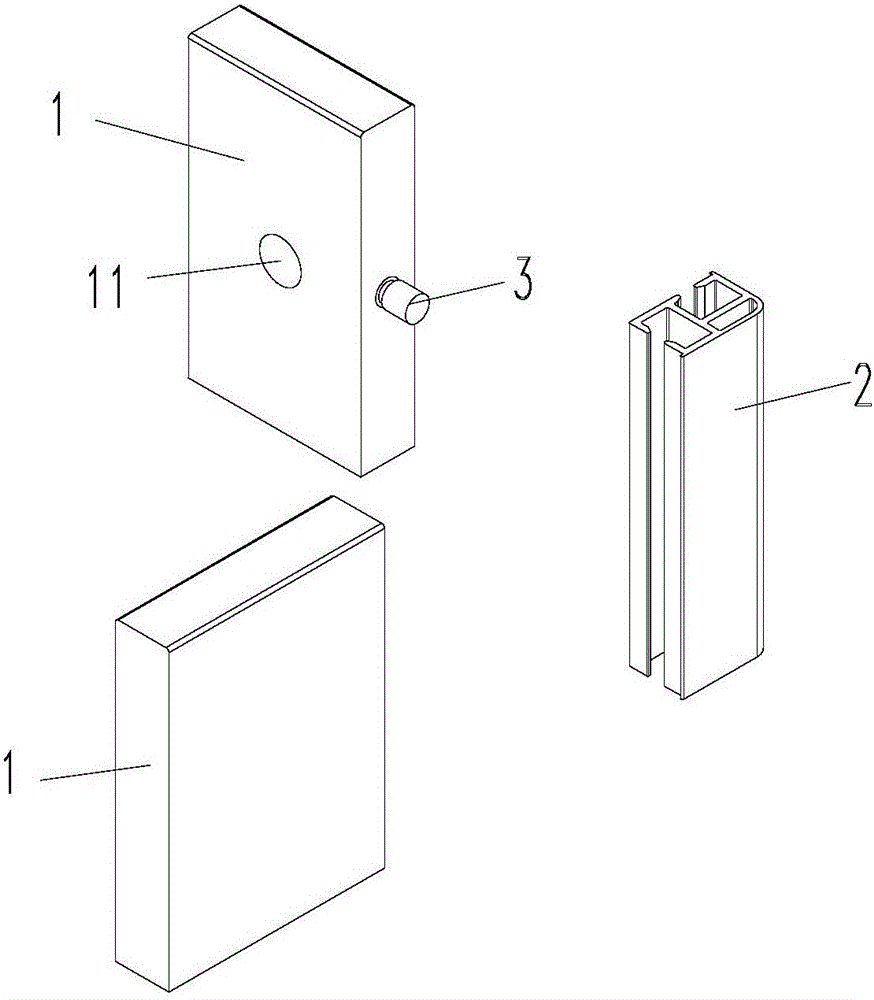

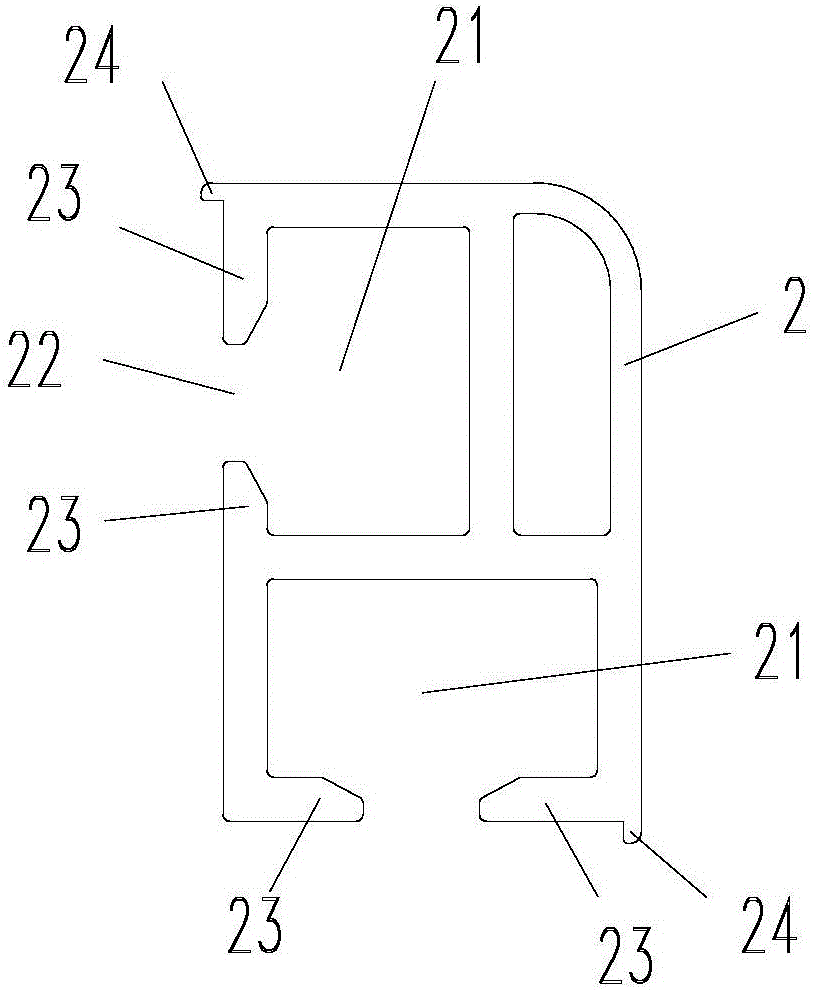

[0038] In this embodiment, the board connection structure is described by taking the connection of two boards as an example. The structure is as follows Figure 1 ~ Figure 4 As shown; including a cylinder 2, a connecting rod 3 and two plates 1; two sides in the cylinder 2 are respectively provided with positioning grooves 21 along the length direction; each positioning groove notch 22 sides are respectively provided with positioning edges twenty three.

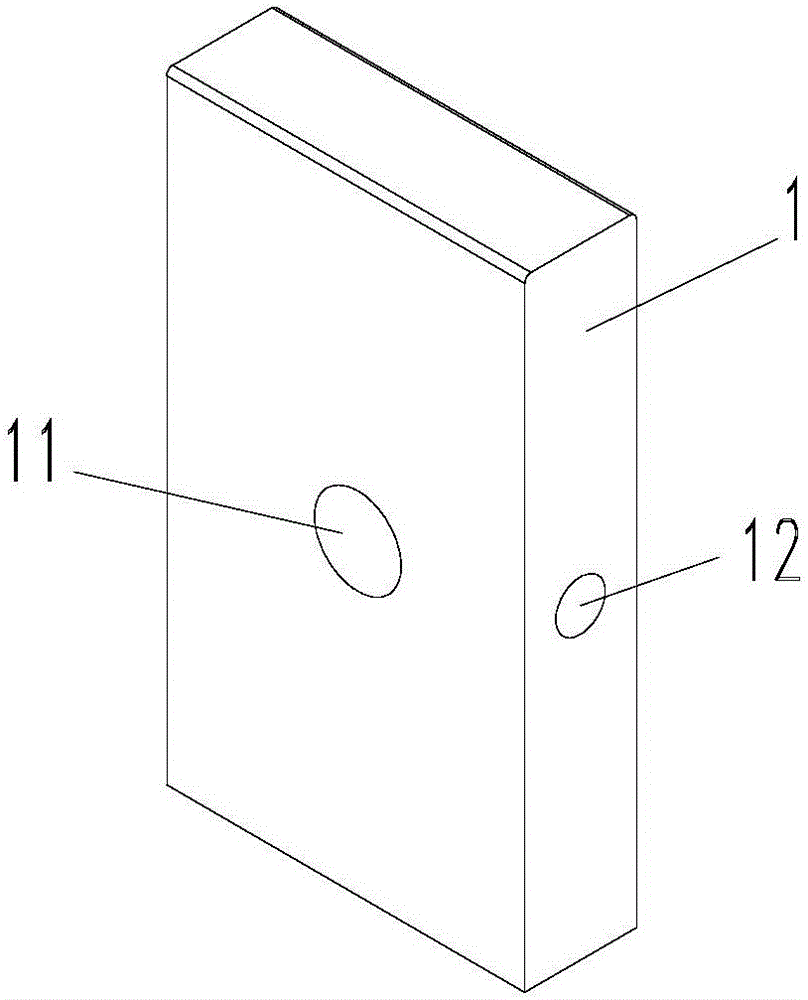

[0039]Each plate 1 is provided with accommodating cavity 11 respectively; the cavity wall of accommodating cavity 11 is provided with positioning hole 12; accommodating cavity 11 is provided with connecting auxiliary parts; in this embodiment, connecting auxiliary parts adopt eccentric wheel 4; accommodating cavity 11 and eccentric The wheel 4 matches; the eccentric wheel 4 can adopt the eccentric wheel in the existing three-in-one connector. One end of the connecting rod 3 is arranged in the positioning groove 21 and fits wi...

Embodiment 2

[0046] The plate connection structure of this embodiment, its structure is as follows Figure 5 and Figure 6 Shown; The difference with Embodiment 1 is: In this embodiment, the upper end and / or lower end of the cylinder 2 is provided with a cover body 5 . The cover body 5 includes a base plate 51 and at least one protrusion 52 clamped in the positioning groove 21 ; the protrusion 52 is connected with the base plate 51 . The advantage of this design is that the structure is simple, and it is convenient to cover the cover body 5 on the column body 2 . The cover body 5 can prevent foreign matter such as dust from accumulating inside the cylinder body 2, which is convenient for cleaning, keeps the product clean, and can also enhance the aesthetic feeling. The rest of the structure of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0048] The difference between the plate connection structure of this embodiment and Embodiment 1 is that: in this embodiment, the connecting rod includes a connecting rod body and a positioning piece sleeved on the connecting rod body; one end of the connecting rod body is offset against the positioning edge through the positioning piece , the other end of the connecting rod body passes through the positioning hole and is engaged with the eccentric wheel. The positioning piece and the main body of the connecting rod are set independently, and the positioning piece can be made of a material with certain elasticity, such as plastic, silica gel, etc., which is conducive to further strengthening the stability of the connection between the connecting rod and the column.

[0049] One end of the connecting rod body is provided with a limiting part, the limiting part fits with the positioning part, and the positioning part fits with the positioning edge, so that when the eccentric whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com