A High Linearity Electromagnetic Semi-Active Vibration Absorber

A highly linear, electromagnetic technology, applied in the direction of shock absorbers, magnetic springs, springs/shock absorbers, etc., to achieve the effect of wide linear area and reduced possibility of fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

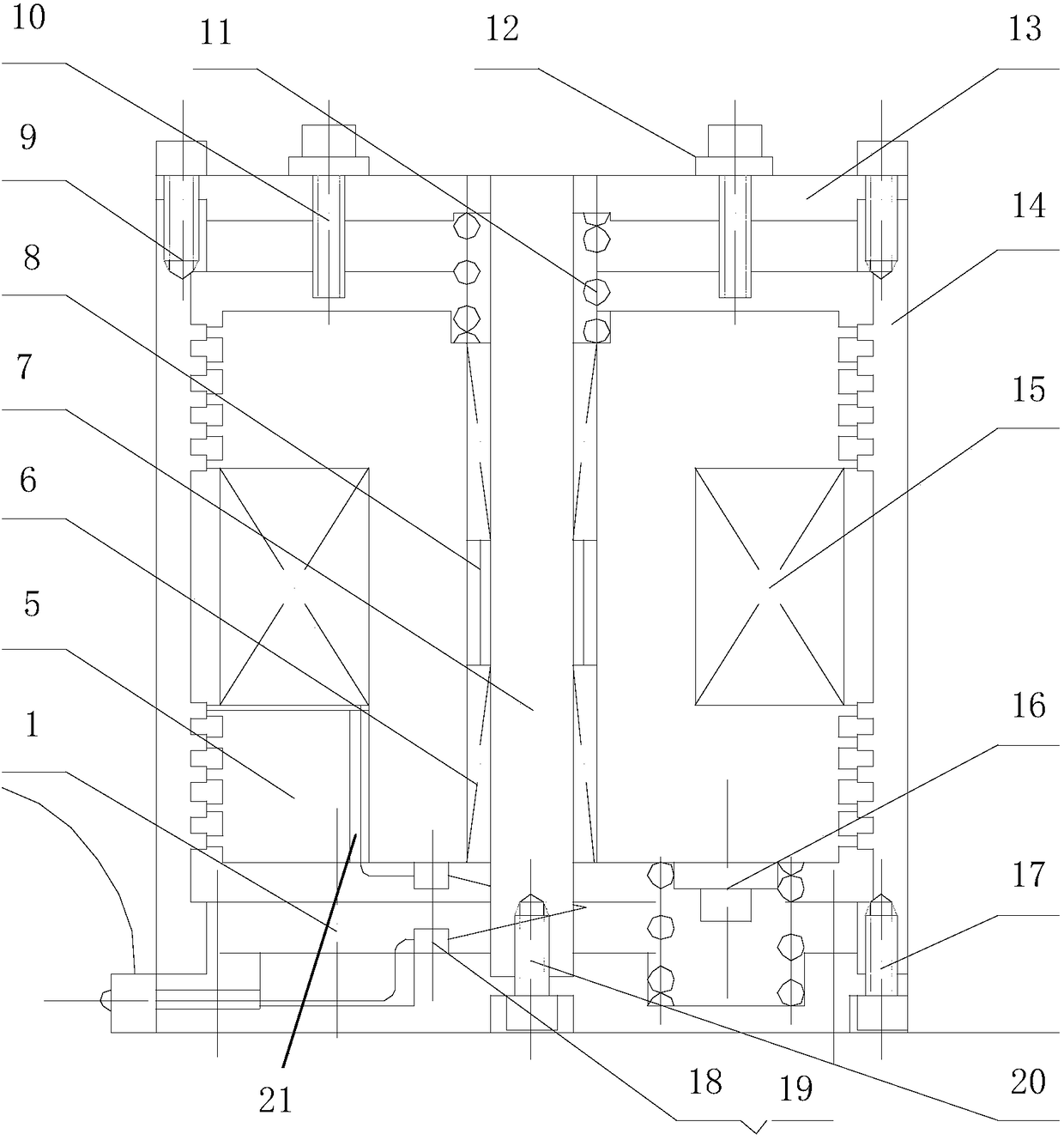

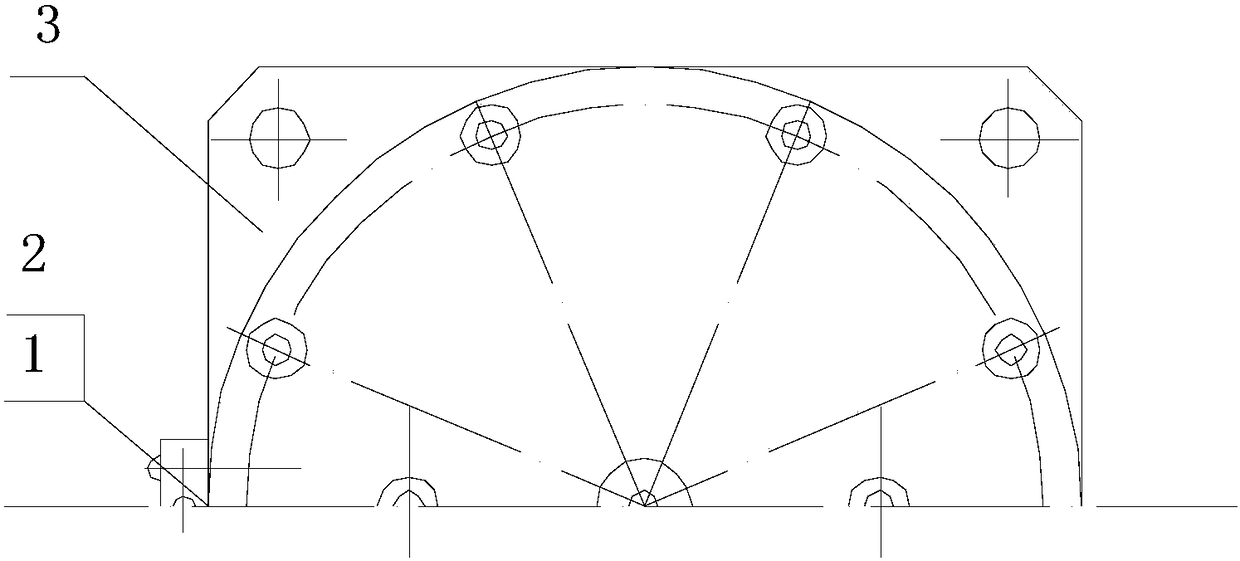

[0018] Example 1: Combining Figure 1~2 , The electromagnetic semi-active vibration absorber of the present invention mainly includes an upper end cover 13, a magnetically conductive outer cylinder 14, an armature 05, a central shaft 07, a lower end cover 03 and the like. The magnetically conductive outer cylinder 14 is respectively connected with the upper end cover 13 and the lower end cover 03 through the hexagon socket bolt 09 and the hexagon socket bolt 17 to form the outer shell of the vibration absorber of the present invention. As a vibration-absorbing mass, the armature 05 is connected to the upper end cover 13 and the lower end cover 03 through the first mechanical spring 11 and the second mechanical spring 04 respectively, and the connecting parts of the armature and the springs are designed with installation grooves or positioning discs 16 . The central shaft 07 passes through the upper end cover 13 and the armature 05 successively from top to bottom, and finally i...

Embodiment 2

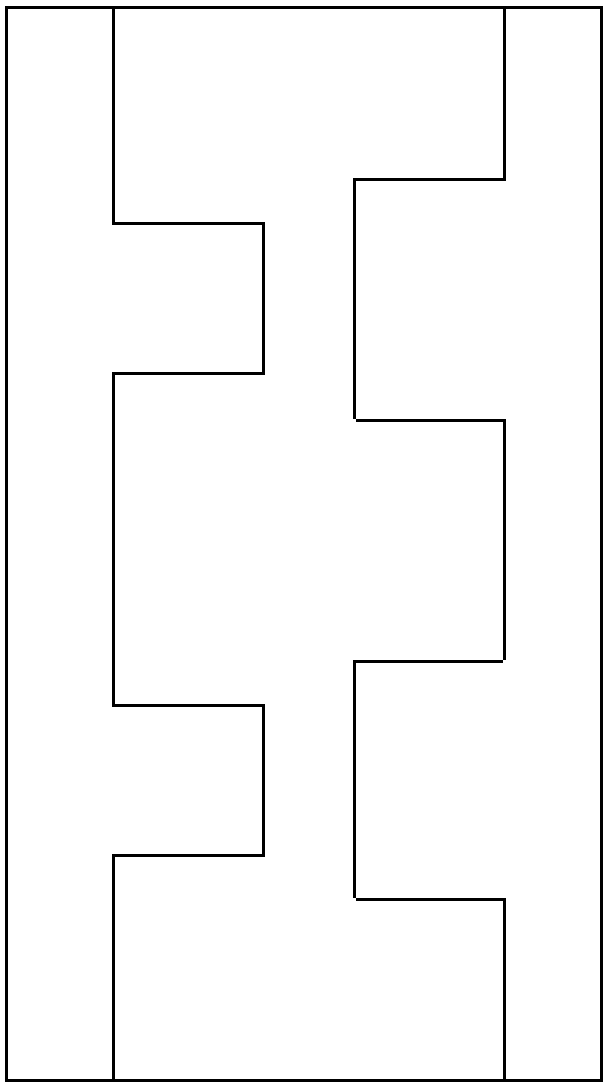

[0020] Embodiment 2: Based on the implementation case 1: the tooth width of the armature ring gear of the present invention is not equal to the tooth width of the magnetically permeable outer cylinder, but satisfies a specific proportional relationship, which is the key to the realization of high linearity in the present invention .

[0021] Figure 3(a) and Figure 3(b) are comparison diagrams between the magnetic tooth structure of the present invention and the traditional magnetic tooth structure, wherein Figure 3(a) and Figure 3(b) respectively represent the unequal width magnetic teeth proposed by the present invention structure and the traditional equal-width magnetic tooth structure. It can be seen from the figure that in the present invention, the tooth width of the ring gear of the magnetically conductive outer cylinder 14 is not equal to the tooth width of the ring gear of the armature 05, but the former is larger than the latter and satisfies a certain proportional re...

Embodiment 3

[0028] Embodiment 3: Based on the above embodiment, the present invention can also be: a second mechanical spring is installed between the armature and the lower end cover, and the number of the second mechanical springs is four.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com