Connecting and load transferring structure for launch canister

A technology of a launch tube and a connecting plate, applied in the field of connecting devices, can solve the problems of difficult control of initial defects, easy occurrence of partial load, low load transmission efficiency, etc., and achieve the effect of improving the load transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

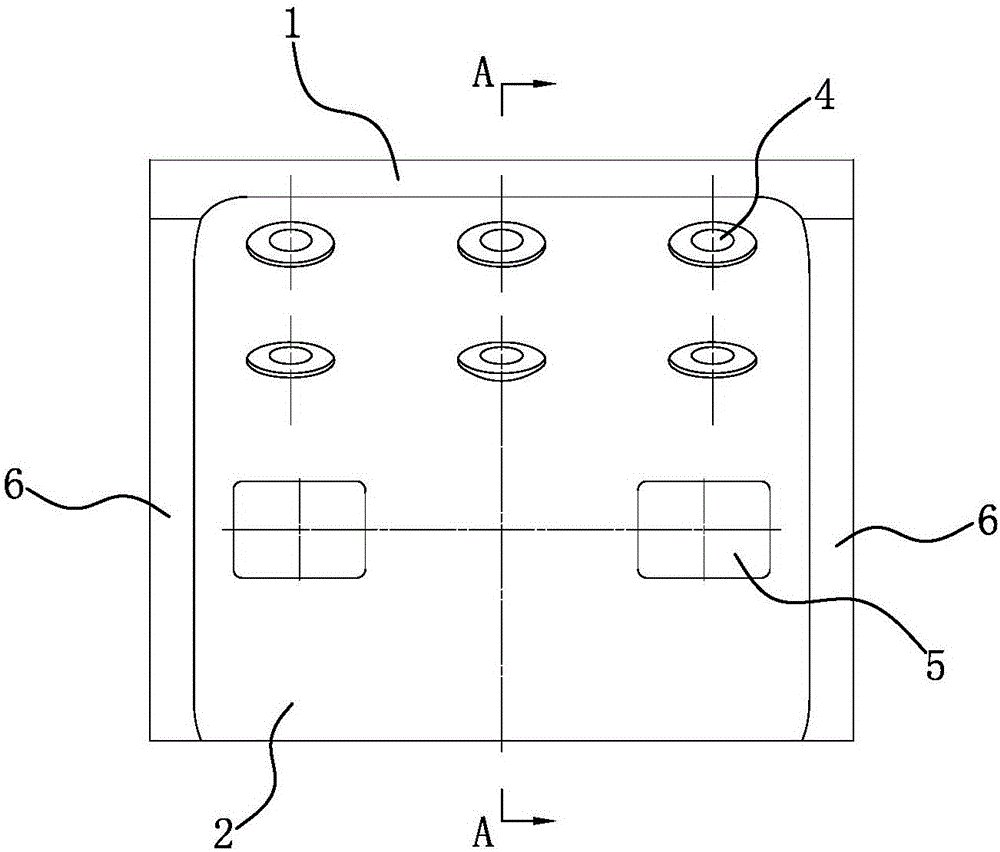

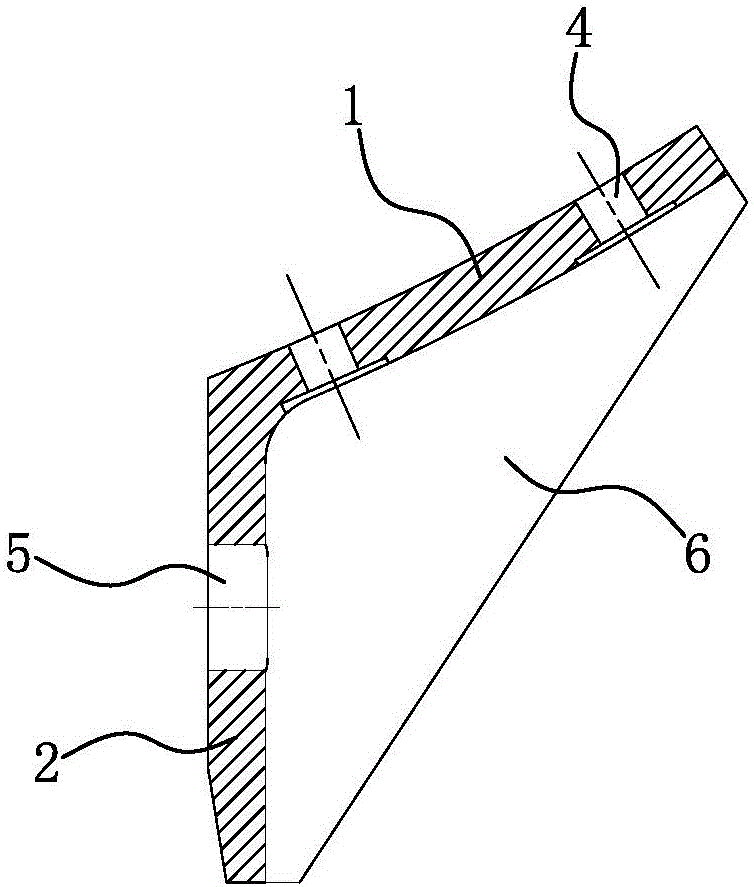

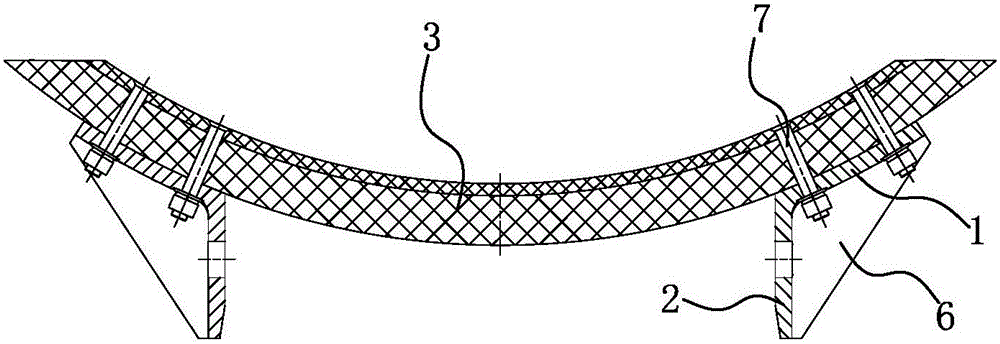

[0017] Such as figure 1 shown, combined with figure 2 As shown, the connecting and carrying structure for the launching tube of the present invention includes a first connecting plate 1 and a second connecting plate 2 fixed to each other, the first connecting plate 1 and the second connecting plate 2 are integrally formed, and the first connecting plate 1 and the second connecting plate The connecting plate 2 is arranged in an approximate L shape. The first connecting plate 1 is used for connecting with the launching tube 3, the first connecting plate 1 is arc-shaped to match the profile of the launching tube 3, the first connecting plate 1 is provided with a connecting hole 4, and the second connecting plate 1 is provided with a connecting hole 4. The connecting plate 2 is provided with a loading interface 5 , and the connecting holes 4 are arranged towards the center of the first connecting plate 1 .

[0018] The connecting carrying structure for the launching tube of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com