Central wing of horizontal tail of civil airplane

A technology for horizontal tail and civil aircraft, applied in aircraft parts, aircraft control, aircraft stability, etc., can solve problems such as poor fatigue performance and pivot 5 failure, and achieve the effect of reducing mass, light weight and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

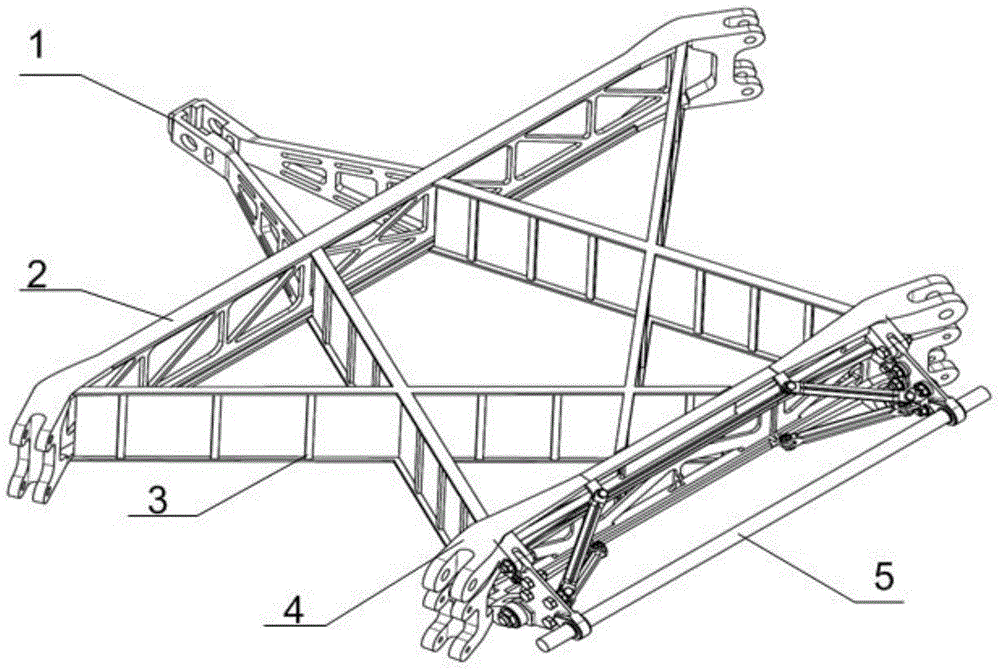

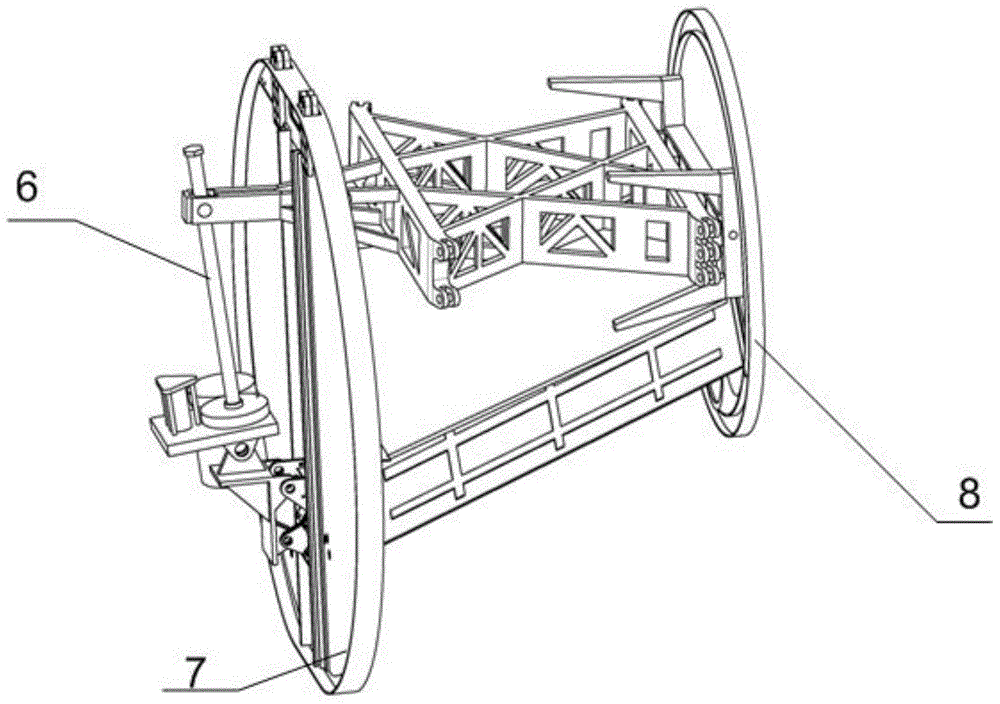

[0022] A kind of civil aircraft horizontal tail center wing of the present invention is described in detail below in conjunction with accompanying drawing.

[0023] (a), for attached figure 2 The working principle of the Boeing B737 horizontal tail adjustment installation angle mechanism shown is: the rear fuselage frame A is connected to the lower support of the screw, generally a little in front of the front beam of the horizontal stabilizer, and the specific position needs to be obtained after coordination. The screw rod 6 is driven by a servo motor or a hydraulic motor to rotate, and drives the screw support 1 connected to the screw rod 6 to move in the vertical direction. Since the rear beam 4 and the rear fuselage frame B8 are hinged by the pivot shaft 5, the actual horizontal tail center wing The movement is the change of the angle, and the movement mechanism of the adjustable horizontal tail installation angle;

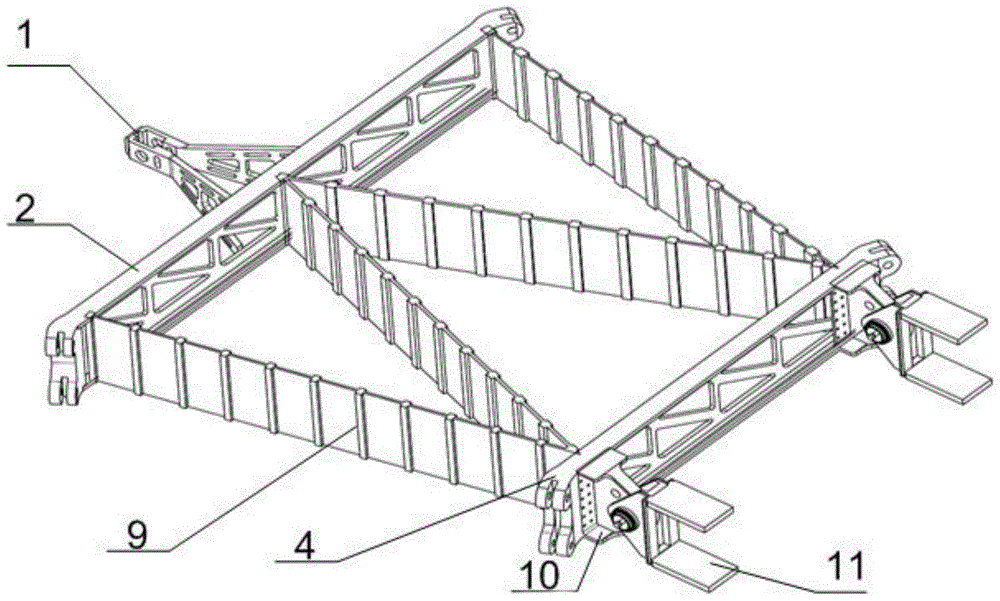

[0024] (b), for attached image 3 Shown is a schemati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com