Aging equipment and aging method for electric welding mask

A technology for aging equipment and face shields, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., and can solve the problems of high failure rate of automatic dimming welding mask production, loss of users and factories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

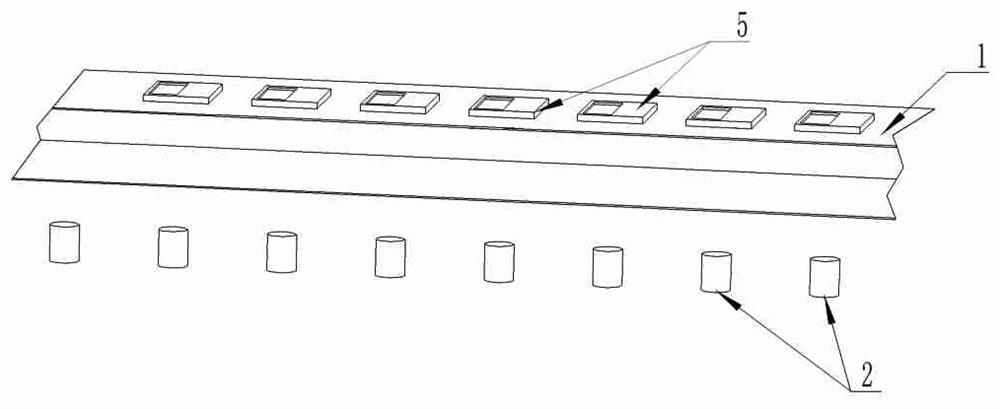

[0018] Such as figure 1 As shown, the moving part 1 is an assembly line conveying equipment, and a transparent pure polyurethane PU conveyor belt can be used. The triggering part 2 uses a radiation light source, such as an infrared bulb or an infrared LED. The automatic darkening filter 5 of the welding mask is placed on the moving part 1. The moving part 1 can move at a constant speed according to the set direction and speed, and drive the automatic darkening filter 5 of the electric welding mask placed on it to move accordingly, and the triggering part 2 can send out changing infrared light according to the set mode, Its on-time (that is, the time when the power is turned on and emits infrared light) can be set arbitrarily between 1ms and normally open, and its off-time (that is, the time when the power is turned off without infrared light) can be set arbitrarily between 1ms and normally closed; In this way, the automatic darkening filter 5 of the welding mask that completed...

no. 2 approach )

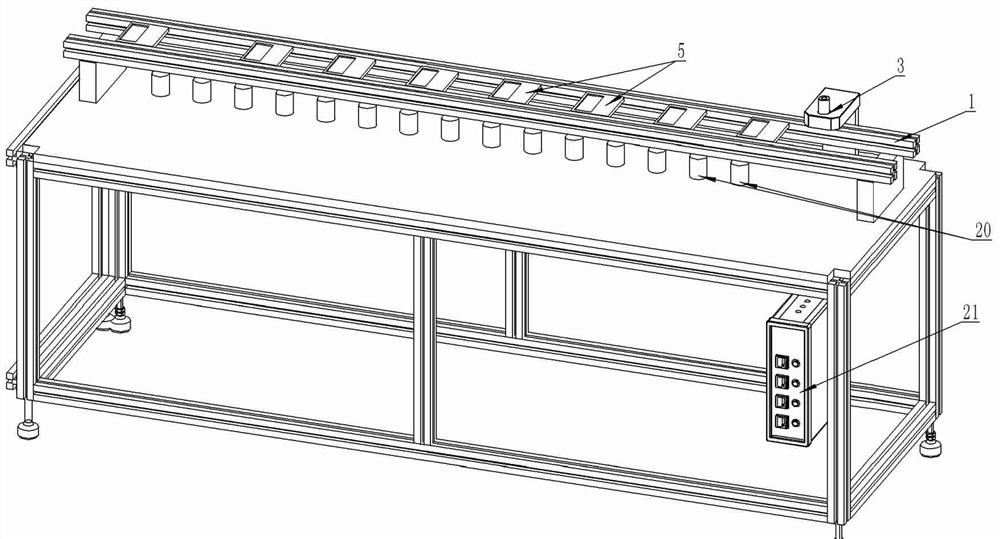

[0020] Such as figure 2 As shown, the moving part 1 is an assembly line conveying equipment, and a chain conveying line with adjustable width can be used. The light source part 20 and the light source control part 21 form the trigger part 2 (not shown in the figure), and the automatic darkening filter 5 of the welding mask is placed On the moving part 1; the moving part 1 can do intermittent movement according to the set direction and speed, and drive the automatic darkening filter 5 of the electric welding mask placed on it to move accordingly. The infrared LEDs of the segment, the light source control part 21 can respectively control the above-mentioned infrared LEDs that are connected into several segments to emit changing infrared light according to the set mode; For the various working parameters of the optical filter 5, if any product is damaged in the aging process, it can be picked out through this step to ensure the pass rate of the product.

no. 3 approach )

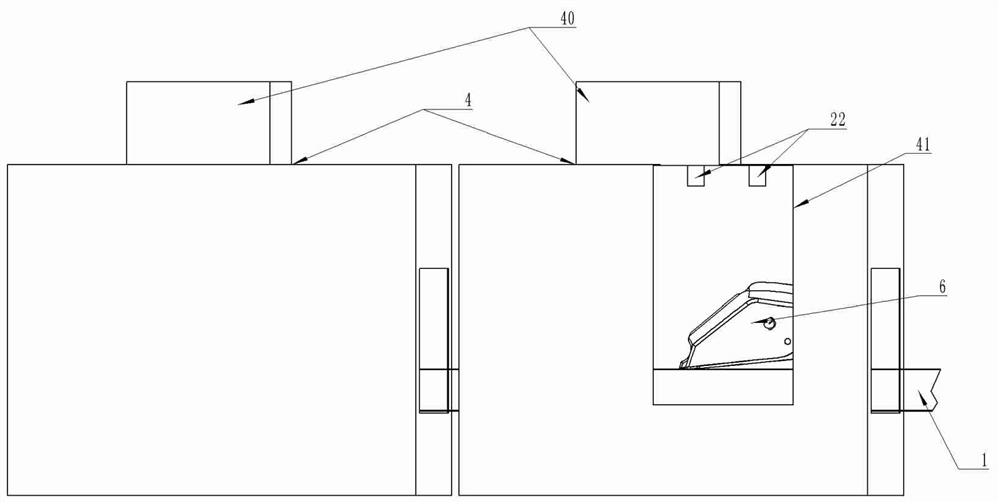

[0022] Such as image 3 As shown, the moving part 1 is an assembly line conveying device, and a Teflon conveyor belt can be used. The temperature-controllable blowing device 40 is installed on the casing 41 to form a temperature control part 4. Each welding mask aging equipment includes at least one temperature control part 4 , the moving part 1 passes through the temperature control part 4, the light source 22 can adopt an illumination source, such as an incandescent lamp, and the temperature-controllable blower 40 can adopt a temperature-adjustable hot air blower or a cold air blower for controlling the temperature in the temperature control part 4. Temperature: the automatic darkening welding mask 6 is placed on the moving part 1, and the aging process is carried out during the movement therewith, and at the same time, because the ambient temperatures flowing through different temperature control parts 4 are different, better aging can be achieved Effect.

[0023] In the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com