A rotor gap adjustment device for an automobile cooling fan motor

A gap adjustment device and cooling fan technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems that the stability of the motor quality cannot be guaranteed, and the time-consuming adjustment of the axial gap can be solved. Smooth, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below through specific examples.

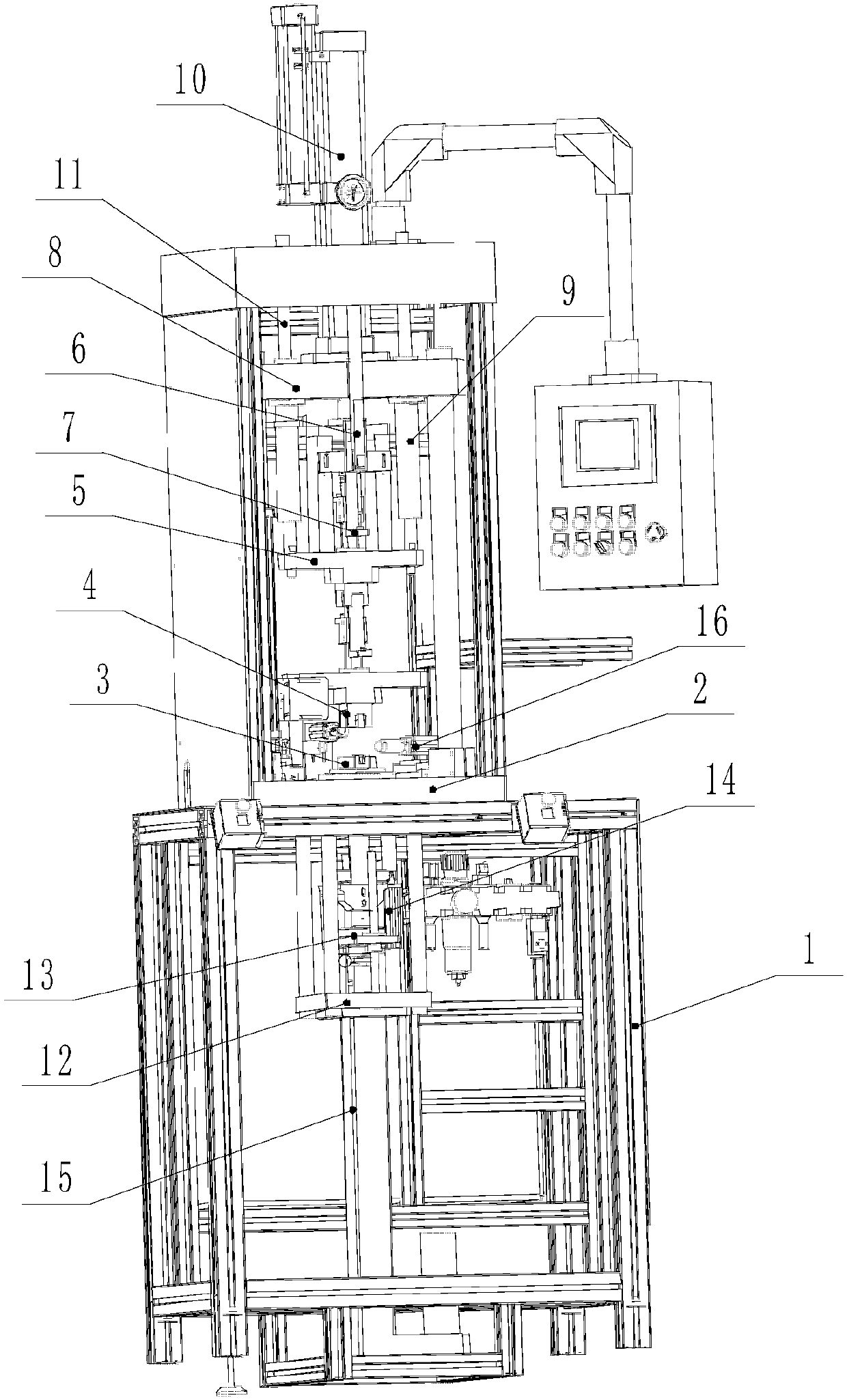

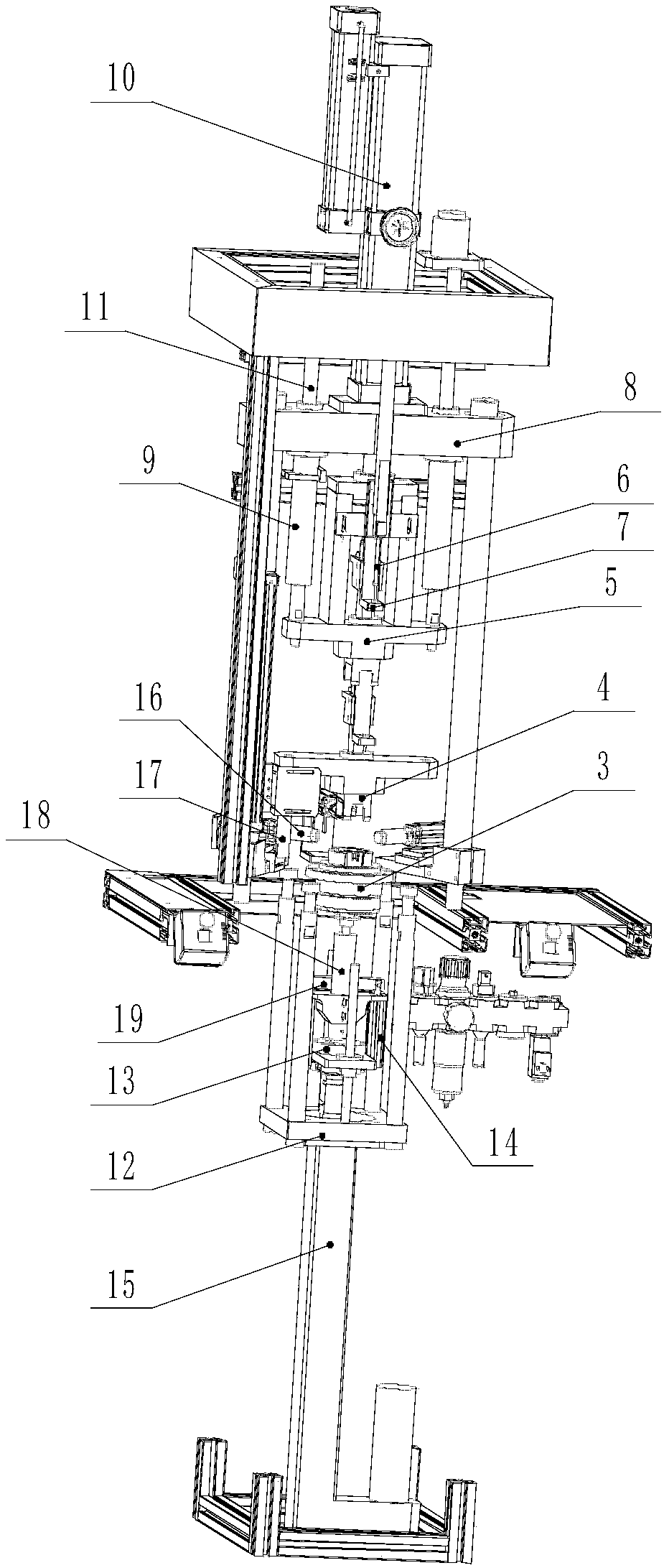

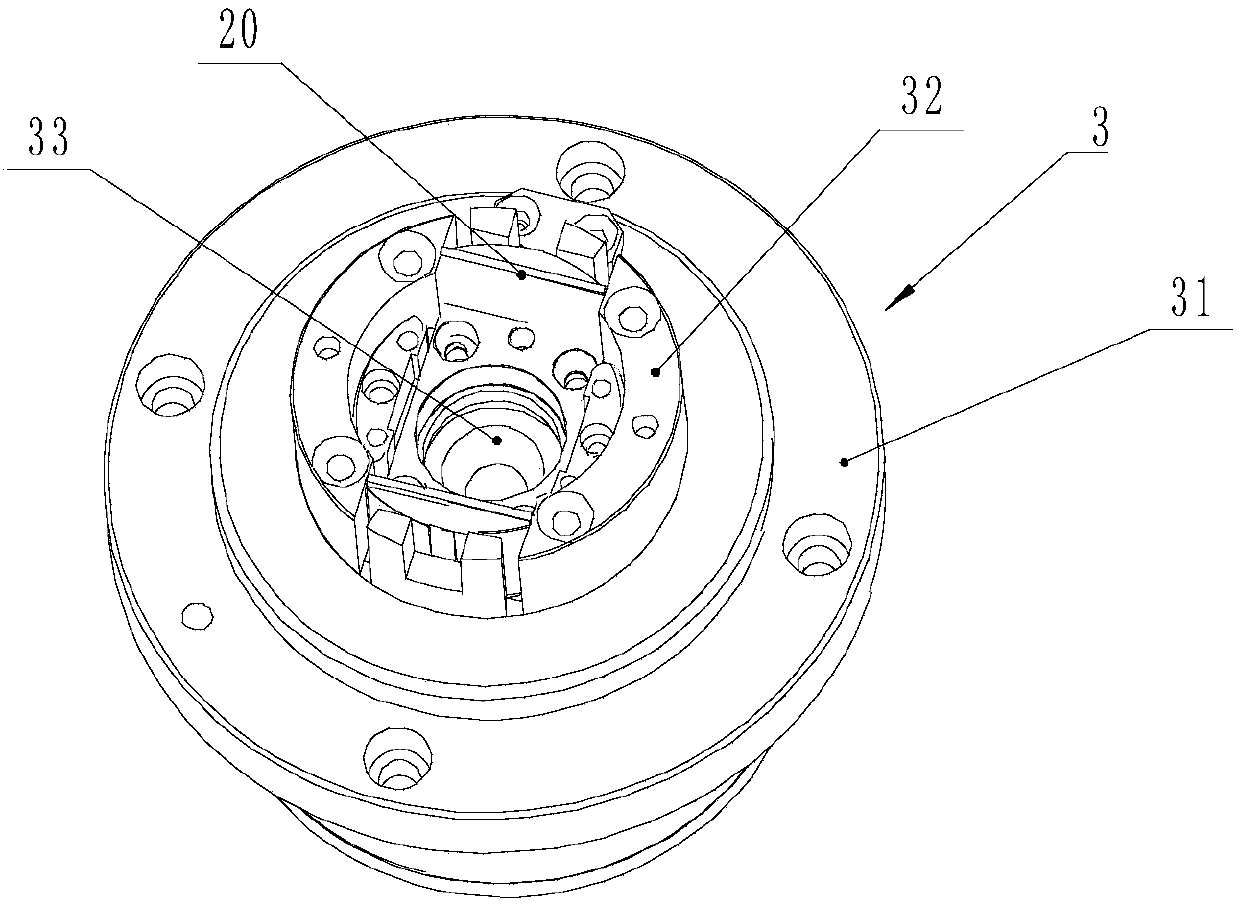

[0026] Such as figure 1 As shown, a rotor gap adjustment device for an automobile cooling fan motor includes a frame 1, an operating platform 2 is arranged on the frame 1, and a concave recess matching the front end cover 22 of the motor is fixed on the operating platform 2. Die 3, described lower die 3 is provided with the jack 33 that facilitates the insertion of the front end of motor rotor shaft 21, vertically slides on the described lower die 3 and is equipped with two front-end covers 22 for symmetrically pressing the motor to make it The top pressure block 20 of axial deformation, the lower end of the operating platform 2 on the frame 1 is vertically slidably equipped with a lower seat 13, and the lower seat 13 is driven by the lower seat lifting power device 15, such as figure 1 and figure 2 Shown, be positioned at the below of operating platform 2 on the frame 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com