High-precision variable air volume venturi valve

A variable air volume and Venturi technology, which is applied in the field of high-precision variable air volume Venturi valves, can solve the problems that the Venturi valve cannot accurately control the air volume adjustment process, the Venturi valve air volume adjustment structure is complex, and the adjustment accuracy is low, and the structure is simple. , Occupy small production space, compact volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

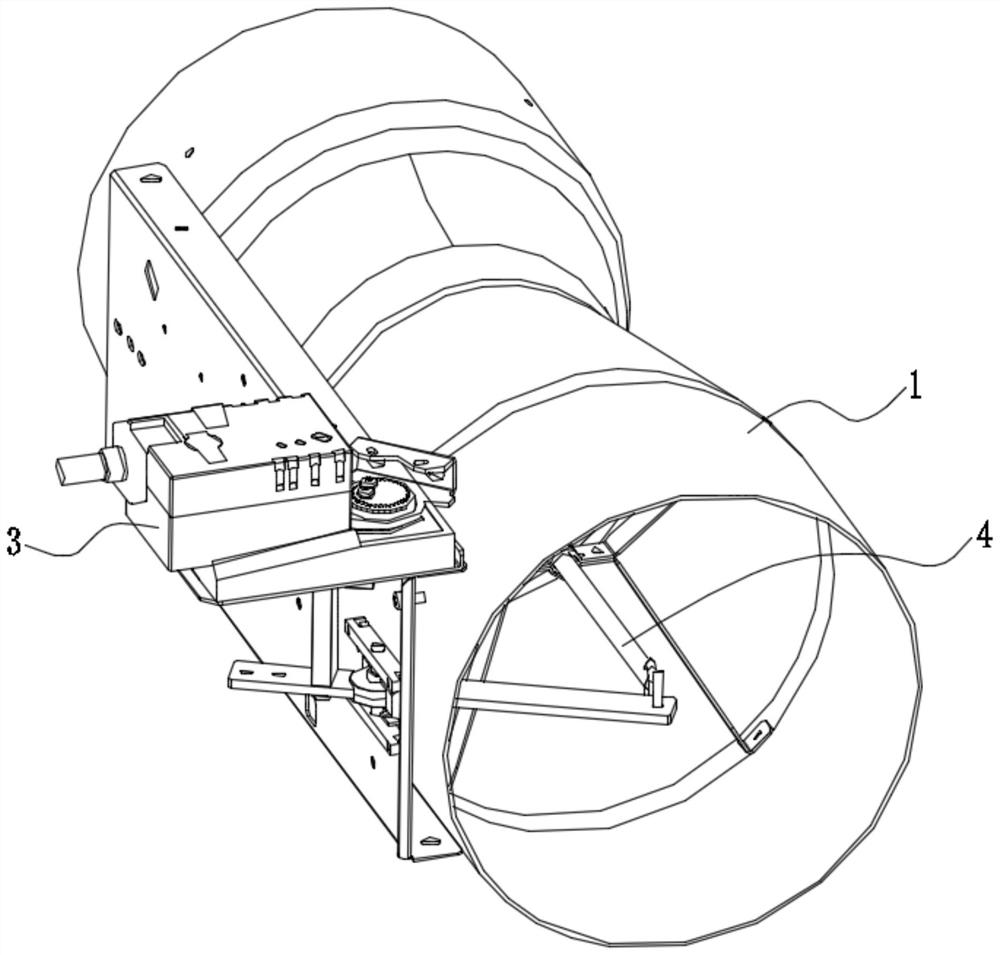

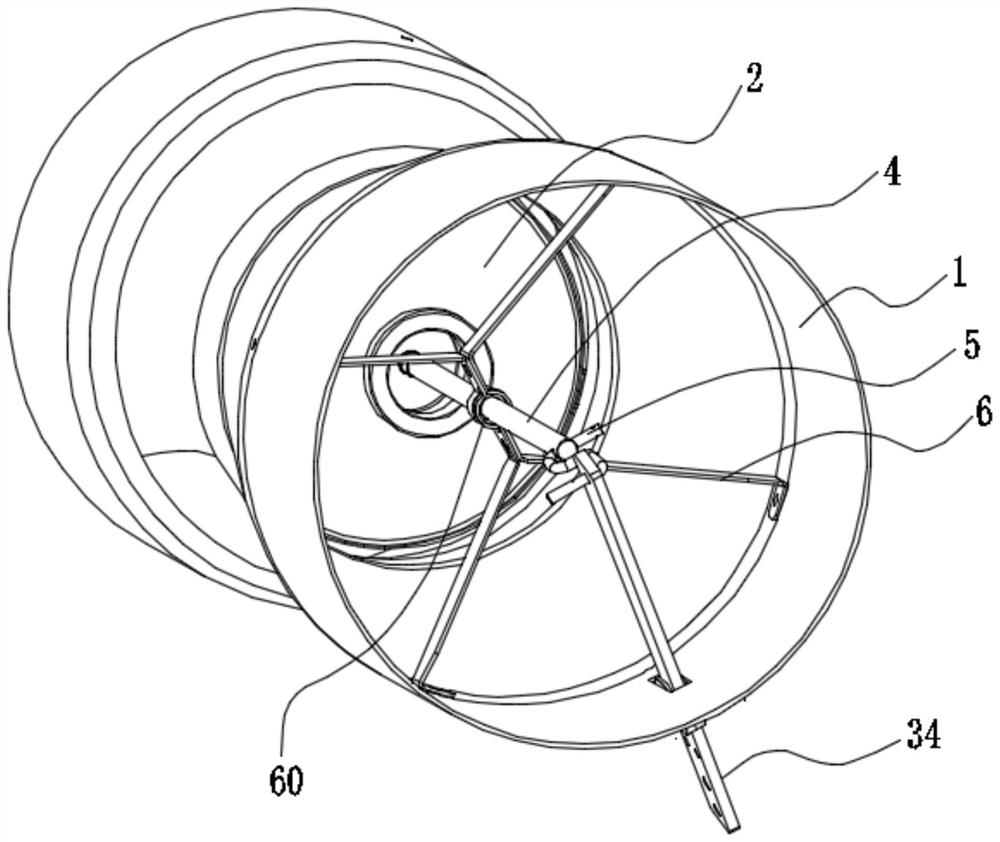

[0028] Please refer to Figure 1-Figure 6 , the present invention provides a high-precision variable air volume Venturi valve, including: a valve body shell 1, a valve core 2 arranged in the valve body shell 1, an air volume adjustment mechanism 3, and a mobile valve connected to the air volume adjustment mechanism 3 Rod 4, the valve core 2 is sleeved on the moving rod 4; the air volume adjustment mechanism 3 is used to drive the moving rod 4 and the valve core 2 to move up and down, thereby changing a high-precision variable air volume in the present invention The cross-sectional area of the valve bore of the Venturi valve changes the ventilation volume.

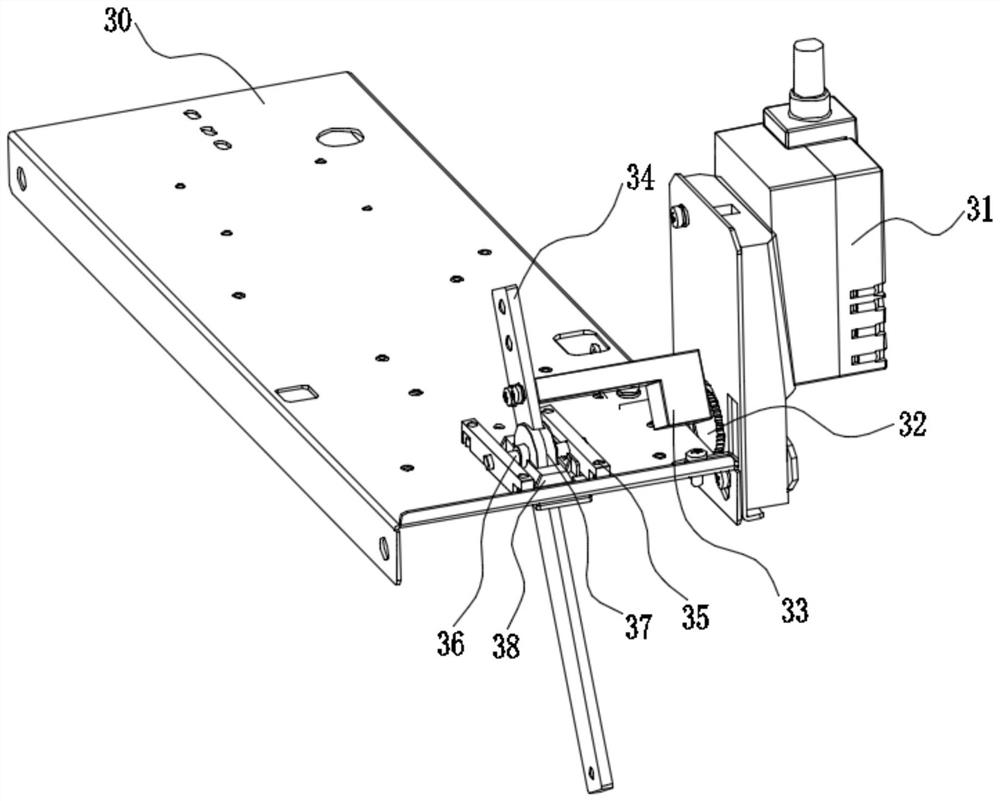

[0029] Specifically, in this embodiment, the air volume adjustment mechanism 3 includes: a mounting plate 30 fixed on the valve housing 1 , a damper actuator 31 mounted on the mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com