Dental handpiece driller clamping device

A dental handpiece and clamping device technology, which is applied in dentistry, dental drilling, medical science, etc., can solve the problems of not clamping the needle tightly, affecting the user experience, and laborious needle replacement, etc., to achieve increased speed and large clamping force , long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

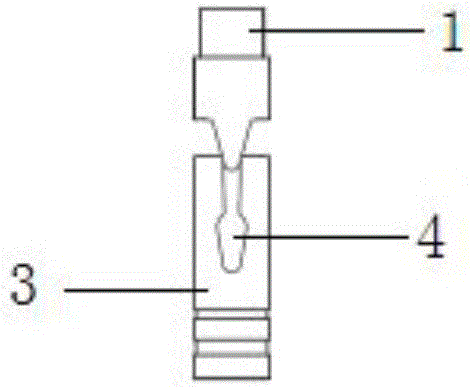

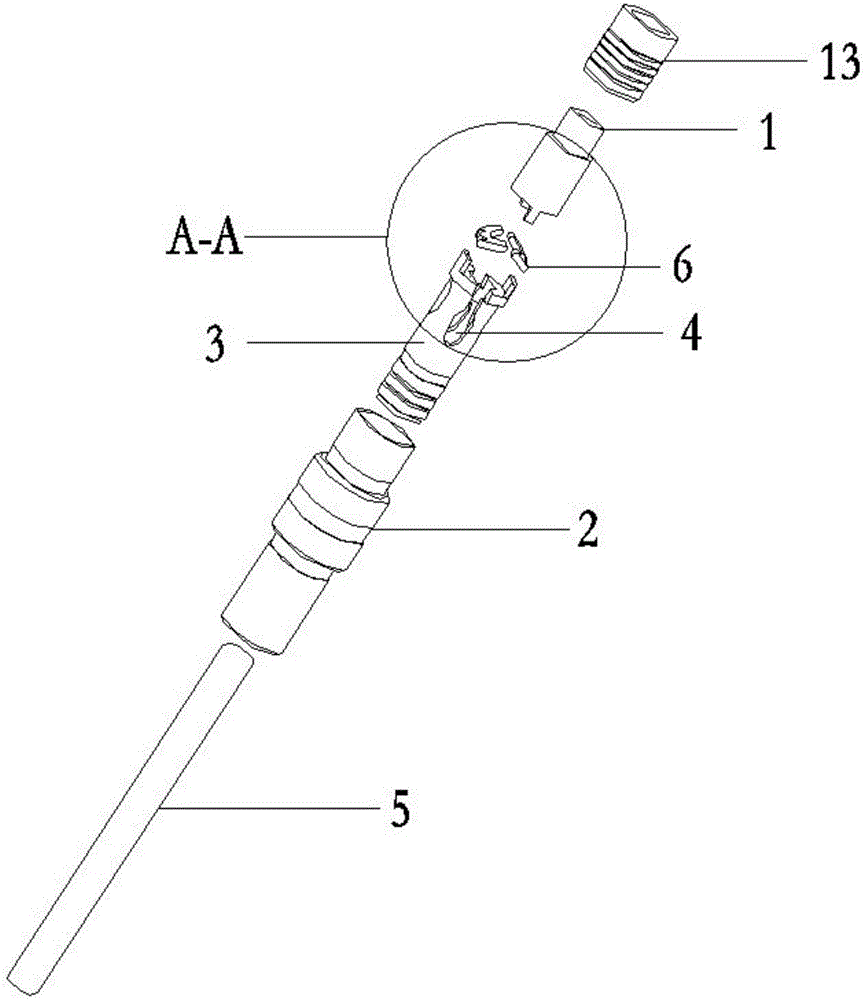

[0031] Such as figure 2 As shown, a dental handpiece bur clamping device includes a pressing member 1 and a bushing 2, the pressing member 1 can slide up and down at the top of the bushing 2, and the upper end of the pressing member 1 extends Out of the top of the shaft sleeve 2 , between the pressing member 1 and the needle clamping member 3 is provided a guide sleeve 13 for guiding the pressing member 1 to slide up and down. A needle holder 3 is provided inside the bushing 2 and corresponding to the position below the pressing member 1, and the side wall of the top of the needle holder 3 is provided with two vertically arranged gaps that can be opened under pressure. 4. Pressing down on the pressing part 1 can squeeze the top of the needle clamping part 3 so that the notch 4 opens and clamps the bur 5 in the needle clamping part 3, and the inside of the bushing 2 corresponds to the pressing An elastic piece is provided between the piece 1 and the needle clamping piece 3 to...

Embodiment 2

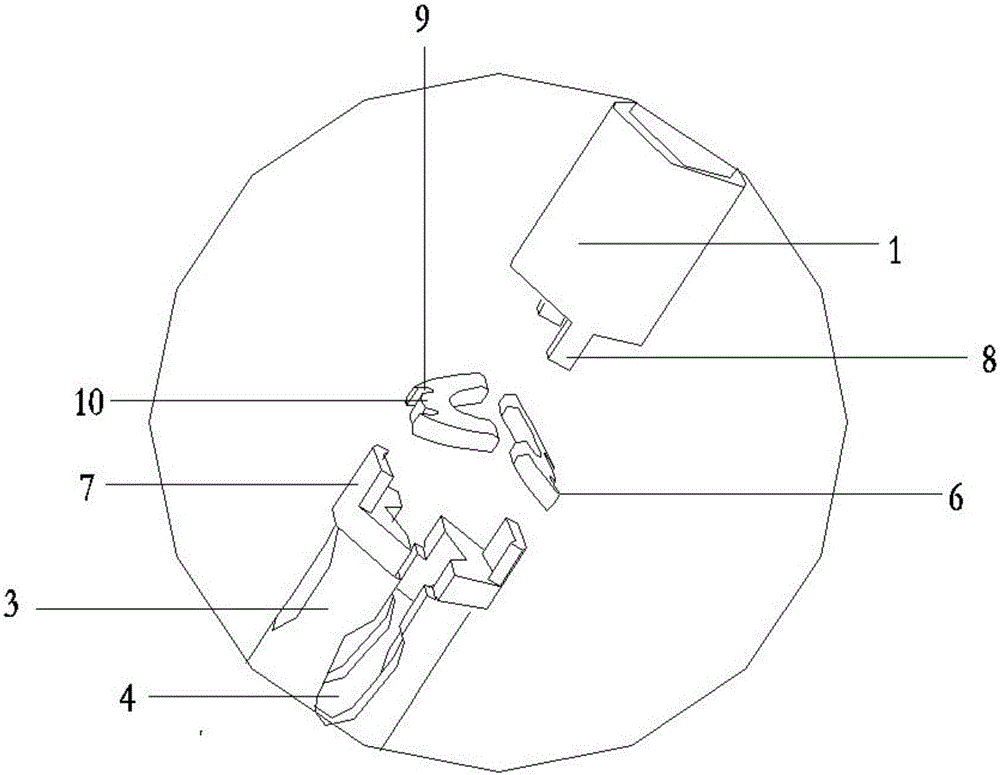

[0035] Figure 4 It is a schematic diagram of the second embodiment of the elastic member, and the structural principle of the other parts of the clamping device is the same as that of the first embodiment except the elastic member. The elastic member is two V-shaped elastic pieces 6 arranged symmetrically with respect to the axis of the pressing member 1. A vertically upward extrusion block 11 is provided at the opening of the V-shaped elastic piece 6. The top of the needle clip 3 The outer periphery is provided with a baffle plate 7 that extends upward and is oppositely arranged. The closed ends of the V-shaped elastic pieces 6 are against the baffle plate 7 respectively, and the top of the extrusion block 11 of the V-shaped elastic piece 6 is against the top of the pressing piece 1. bottom, and the V-shaped shrapnel 6 is arranged obliquely upward in the direction from its closed end to its open end. The clamping device using the above-mentioned elastic member also inherits...

Embodiment 3

[0037] Figure 5 It is a schematic diagram of the third embodiment of the elastic member. The structural principle of the other parts of the clamping device except the elastic member is also the same as that of Embodiment 1. The elastic member is curved upwards, and the needle clamping member 3 An upwardly extending and opposite baffle plate 7 is provided on the outer periphery of the top, the two ends of the elastic member are against the baffle plate 7 respectively, and the highest point of the elastic member is against the bottom of the pressing member 1 . The elastic member is provided with a through hole 12 for the elastic member to be easily deformed under force. The clamping device using the above-mentioned elastic member can also achieve the beneficial effects of the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com