Heating plaster

A heating paste and heating layer technology, which is applied in the field of daily necessities, can solve the problems of inconvenient stretching and bending of joint parts, and the powder of the heating layer is easy to fall to the bottom, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

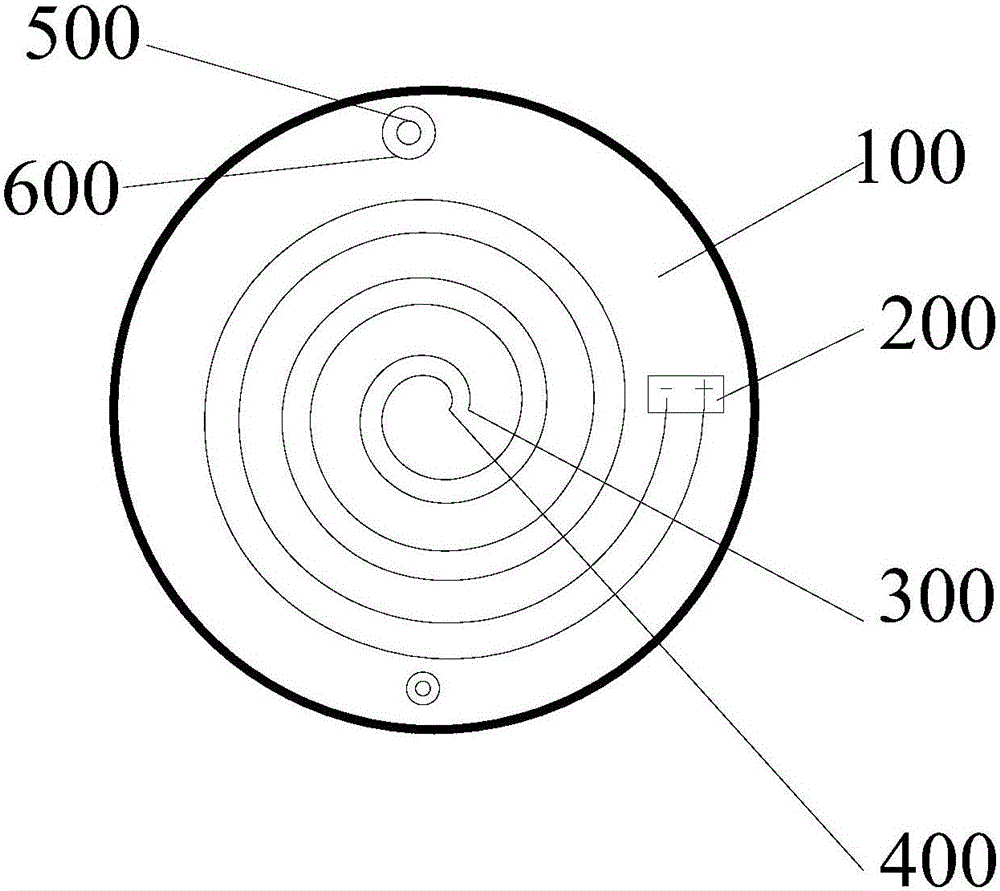

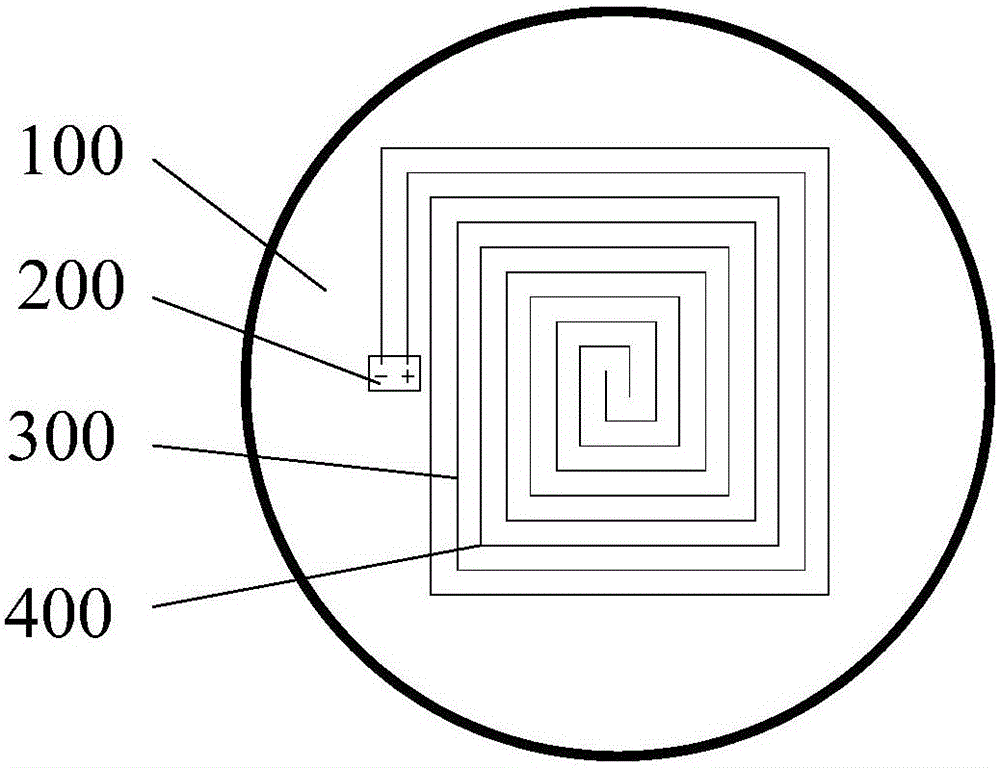

[0090] A heating paste, including a heating layer 7, a microcurrent layer 10, and an insulating protective layer 8; the microcurrent layer 10 includes a flexible conductive base layer 100 and a microcurrent power supply 200, and the insulating protective layer 8 is wrapped outside the heating layer 7, and is flexible and conductive The base is arranged on the wrapped heating layer 7, and the micro-current layer 10 is in direct contact with human skin.

[0091] The positive electrode of the micro-current power supply 200 is connected to the positive electrode conductive strip 300, and the negative electrode of the micro-current power supply 200 is connected to the negative electrode conductive strip 400; the positive electrode conductive strip 300 is arranged around the first set point in turn around the outer periphery of the first set point The negative electrode conductive strip 400 is arranged around the second set point in turn around the outer periphery of the second set p...

Embodiment 2

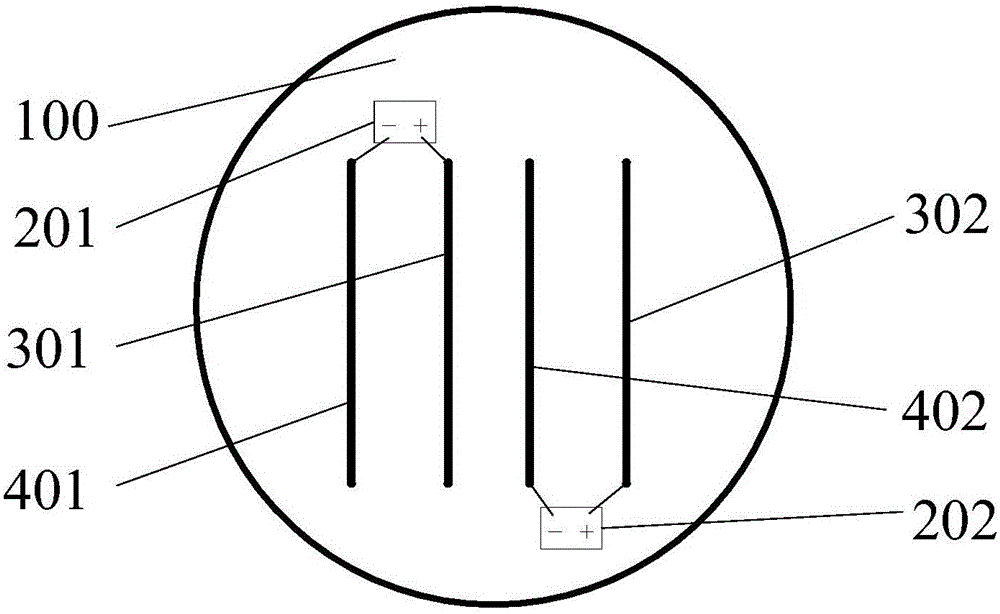

[0096] A kind of heating paste, comprises heating layer 7, micro current layer 10 and insulation protective layer 8; The current power source 202 and the insulating protection layer 8 are arranged between the flexible conductive base layer 100 and the heating layer 7, and the microcurrent layer 10 is in direct contact with human skin.

[0097] The positive pole of the first microcurrent power supply 201 connects the first positive pole conductive strip 301, and the negative pole of the first microcurrent power supply 201 connects the first negative pole conductive strip 401; The positive pole of the second microcurrent power supply 202 connects the second positive pole conductive strip 302, the second The negative electrode of the microcurrent power supply 202 is connected to the second negative electrode conductive strip 402 . The positive and negative conductive strips are distributed on the flexible conductive base layer 100 at positive and negative intervals, such as the f...

Embodiment 3

[0101] A kind of heating paste, comprises heating layer 7, micro current layer 10 and insulation protective layer 8; The current power source 202 and the insulating protection layer 8 are arranged between the flexible conductive base layer 100 and the heating layer 7, and the microcurrent layer 10 is in direct contact with human skin.

[0102] The positive pole of the first microcurrent power supply 201 connects the first positive pole conductive strip 301, and the negative pole of the first microcurrent power supply 201 connects the first negative pole conductive strip 401; The positive pole of the second microcurrent power supply 202 connects the second positive pole conductive strip 302, the second The negative electrode of the microcurrent power supply 202 is connected to the second negative electrode conductive strip 402 . The positive and negative intervals of the suspended ends of the conductive strips are arranged on the flexible conductive base layer 100, and the incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com