A horizontal dust collector for grain storage and transportation equipment

A technology of conveying equipment and dust collector, which is applied in the field of grain processing machinery and equipment, can solve the problems of polluting the surrounding environment, not having dust removal function, endangering the health of workers, etc., and achieving the effect of large dust removal and filtering area, convenient control and good cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

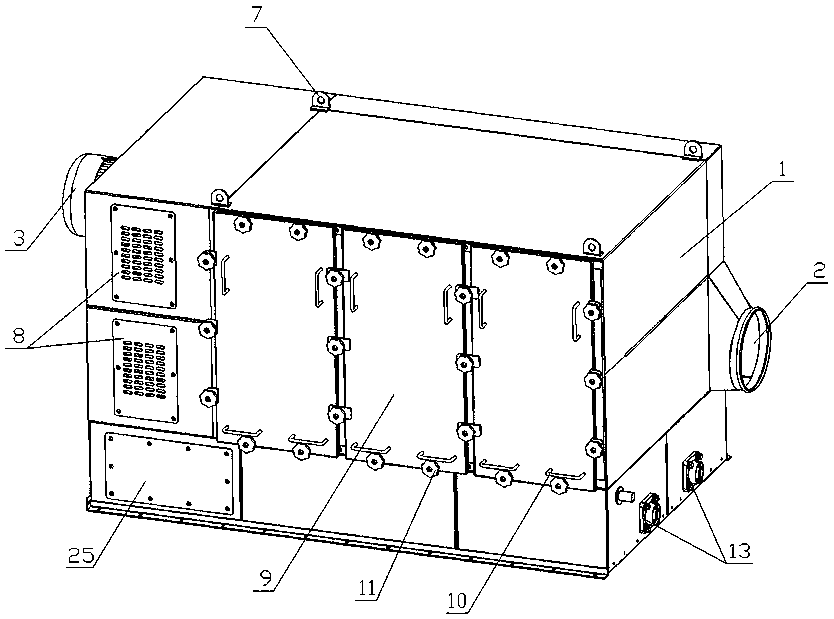

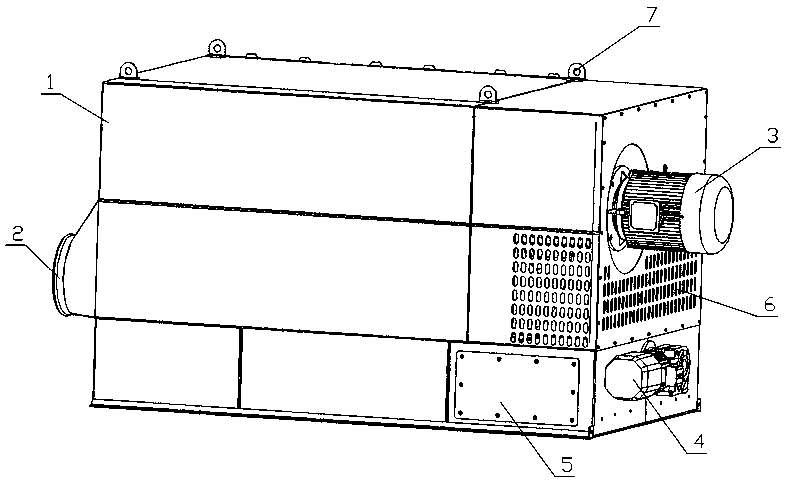

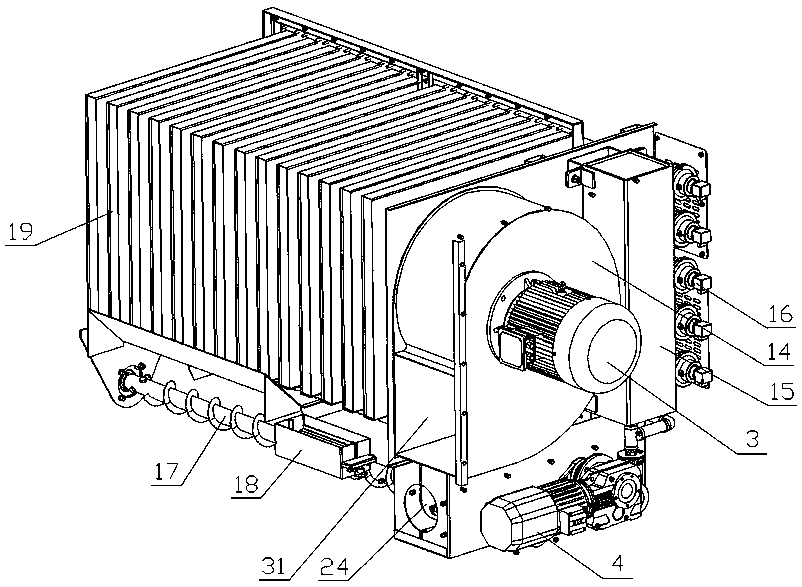

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] as attached Figure 1-12As shown, a horizontal dust collector used for grain storage and transportation equipment includes a casing 1, a dust inlet 2 arranged on the casing 1, a fan 14 arranged on the casing 1, and a fan suction of the fan 14. The suction chamber connected with the tuyere, the dust removal chamber connected to the suction chamber on one side, the dust suction port 18 arranged under the dust removal chamber, the gas blowback chamber arranged on the other side of the dust removal chamber and the dust collection chamber arranged under the dust removal chamber The dust suction port 18 includes a dust suction port body, a track 18-4 arranged on the inner wall of the dust suction port body, and an adjustment baffle 18- 3. According to the size of the dust outlet of the grain storage and transportation equipment and the dust impurity content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com