Solvent proportioning system and proportioning method for car washing robot

A robot and solvent technology, applied in chemical instruments and methods, mixer accessories, dissolution, etc., can solve the problems of inconvenient operation, waste of water resources, inability to meet cleaning requirements, etc., and achieve the effect of automatic proportioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

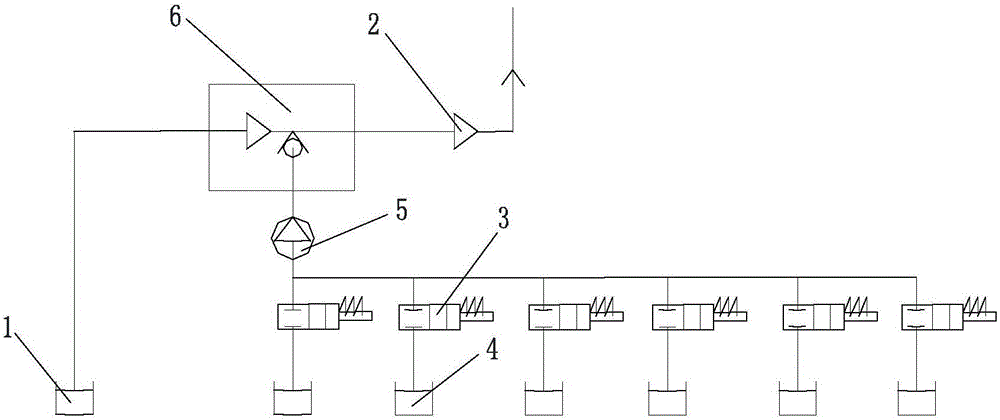

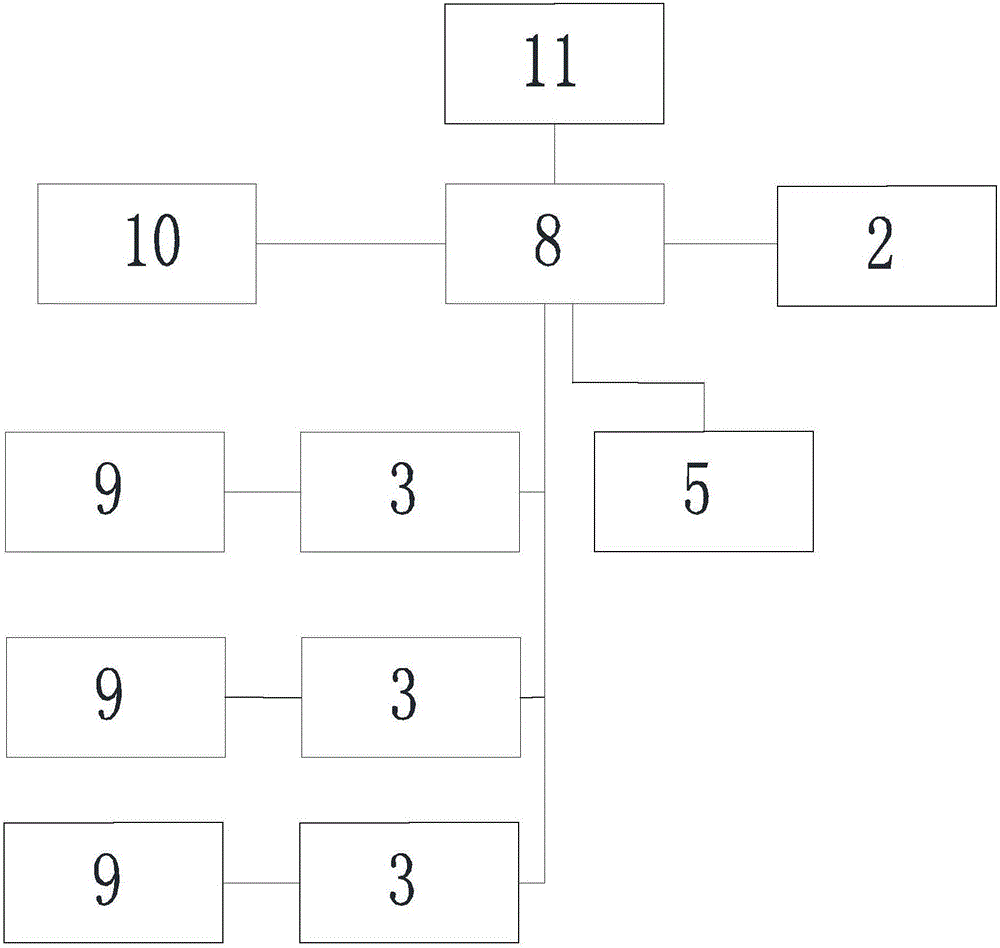

[0019] Such as figure 1 and 2 As shown, a solvent proportioning system for a car washing robot includes a water tank 1, a diaphragm pump 2, a plurality of solenoid valves 3, a plurality of solvent tanks 4, a peristaltic pump 5 and a mixing device 6; An electromagnetic valve 3 is provided, and all the electromagnetic valves 3 are communicated with the peristaltic pump 5, and the peristaltic pump 5 and the diaphragm pump 2 are both communicated with the mixing device 6, and the diaphragm pump 2 is also communicated with the water tank 1 through the mixing device 6 , also includes a control module 8, the control module 8 is electrically connected with the solenoid valve 3, the peristaltic pump 5 and the diaphragm pump 2 respectively; the mixing device 6 is a Venturi tube; it also includes a plurality of control switches, each of which Control switch 9 is all installed on the electromagnetic valve 3, and each control switch 9 is all electrically connected with control module 8; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com