Absorbent preparation method

An absorbent and equation technology, applied in the field of absorbent preparation, can solve the problems of complex system and high cost of system equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] This specific embodiment adopts the following technical scheme: it contains a functional module, which is characterized in that, according to the chemical reaction equation, the mixing amount of the reacting substance and water is calculated to realize the automatic ratio; the module includes the ratio calculation, the normal ratio Process control and reset; also includes the following:

[0036] A. According to the normal operation mode, set the lime concentration to 13%, and calculate the mixing amount of water and lime based on the weight ratio and the following formula:

[0037] The total amount of water in the preparation tank: X% = W1 + W2,

[0038] among them,

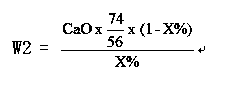

[0039] W1: The amount of water required for the maturation reaction

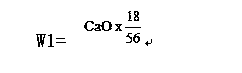

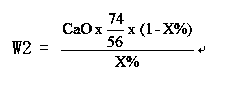

[0040] W2: The amount of water needed to reach the required concentration

[0041]

[0042] Among them, CaO is the required dosage;

[0043]

[0044] Among them, CaO is the required dosage;

[0045] Then the total water volume W3 required to dilute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com