An automatic production line for bolt hot forging diameter reduction

An automatic production line and diameter reduction technology, which is applied in the fields of bolt hot forging and bolt hot forging diameter reduction automatic production line, can solve the problems of low safety, inconsistent chamfer size, and low production efficiency, so as to improve production efficiency and quality, avoid The influence of human factors and the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

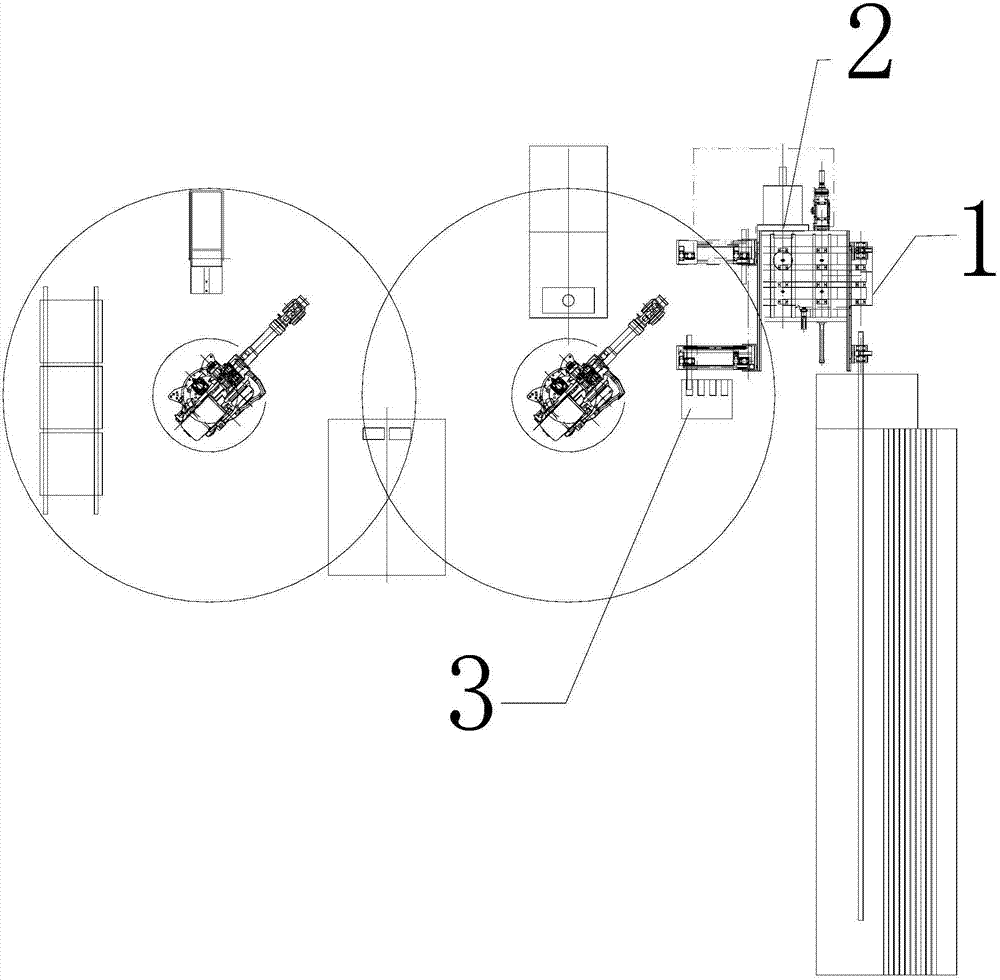

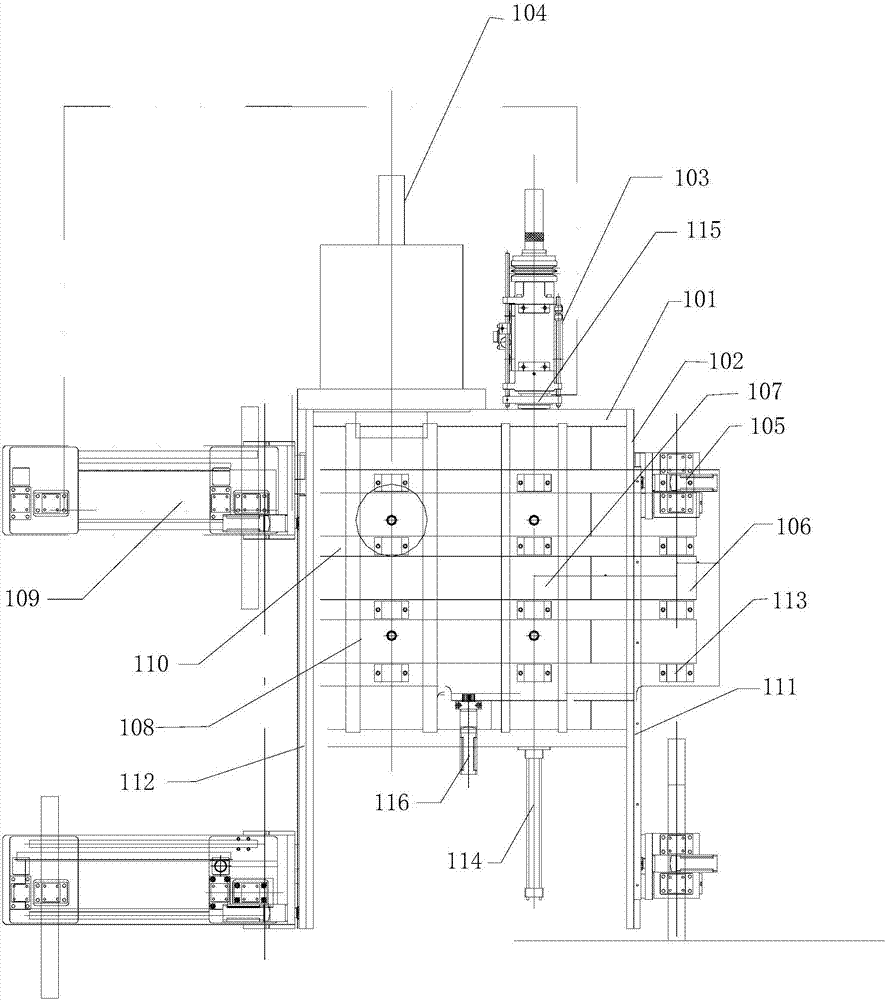

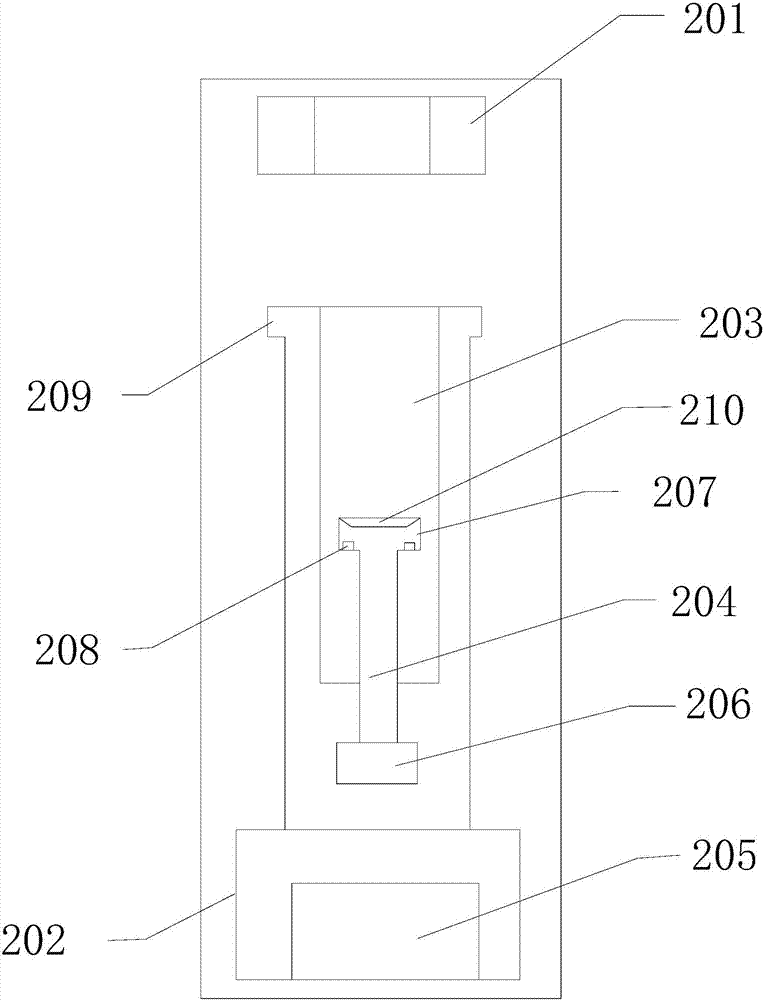

[0015] refer to figure 1 , figure 2 , image 3 and Figure 4, an automatic production line for bolt hot forging diameter reduction in the present invention, comprising a chamfering and diameter reduction integrated machine 1, a diameter reduction cylinder 2, and a temperature-controlled feeding device 3, and the chamfering and diameter reduction integrated machine 1 includes a frame 101, a conveying device 102, chamfering device 103, diameter reducing device 104, described conveying device 102, chamfering device 103, diameter reducing device 104 are all arranged on the frame 101, and described conveying device 102 comprises feeding mechanical clip 105, feeding slide 106 , chamfering slide plate 107, reducing slide plate 108, discharging mechanical clip 109, first guide rail 110, second guide rail 111, third guide rail 112, the quantity of described first guide rail 110 has at least two, and described first guide rail 110 are arranged in parallel, and the feeding slide 106,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com