Universal manipulator assembly of light-weight six-axis robot

A manipulator component and robot technology, applied in the field of robotics, can solve the problems of workpiece falling off, grasping the workpiece, and keeping the movement range of multiple claws consistent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

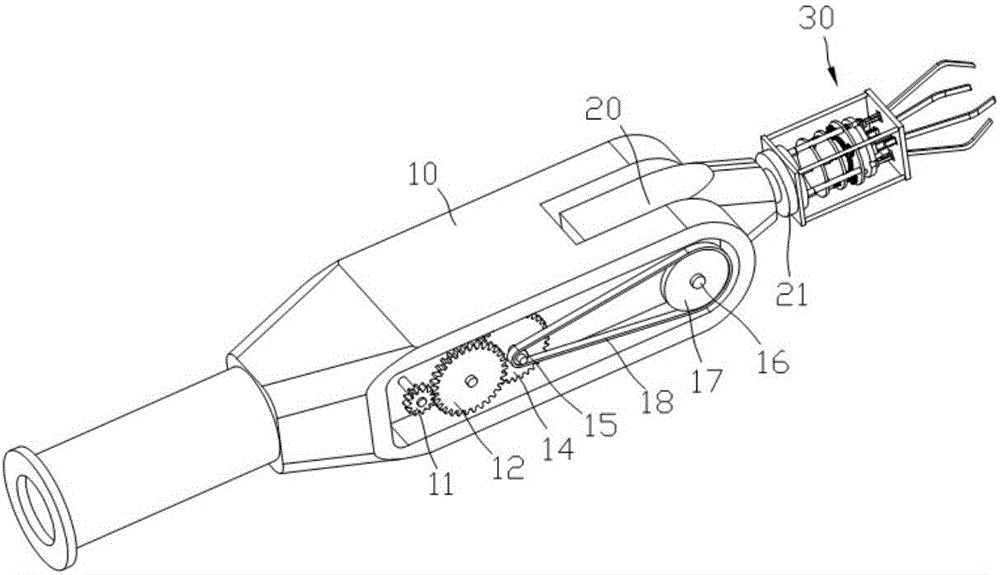

[0034] Such as figure 1 , a manipulator assembly of a light-duty six-axis universal robot, comprising a forearm 10, a swing arm 20 pivotally connected to the front end of the forearm, a first drive unit for driving the swing arm to swing, a mechanical gripper 30 installed at the front end of the swing arm, a drive The second drive unit for the rotation of the gripper; the centerline of the swing arm when swinging is perpendicular to the rotation centerline of the gripper. Wherein, a concave opening is defined at the front end of the small arm 10 , and the swing arm 20 is pivotally connected in the concave opening.

[0035] Such as figure 1 , the first drive unit includes a first motor installed on the forearm 10, a first transmission unit that connects the first motor and the swing arm; the first transmission unit includes a The second gear 12 and the third gear, the fourth gear 14 and the first synchronous pulley 15 that are pivotally connected on the small arm and coaxiall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com