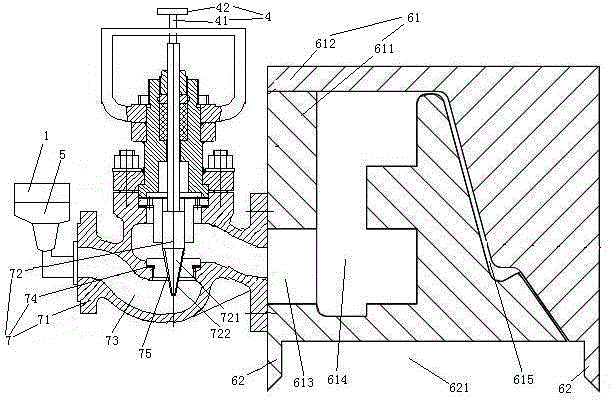

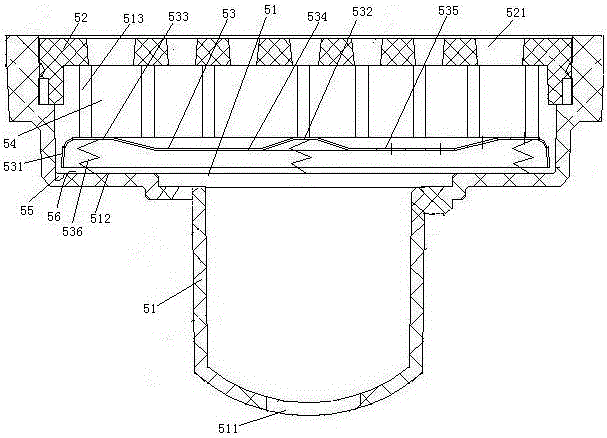

3D printer spray head structure

A technology of 3D printers and nozzles, applied in the direction of additive processing, etc., can solve the problems of fluidity decline, one-way spraying of nozzles, etc., and achieve the effect of convenient internal cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

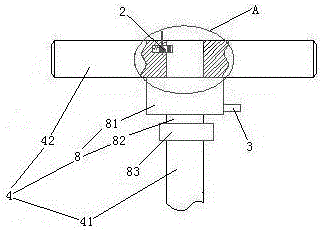

Embodiment 2

[0041] Embodiment two, the difference with embodiment one is:

[0042] see image 3 , The opening and closing valve mechanism 4 also includes a motor 8 and a power switching mechanism 2 . The motor 8 includes a motor housing 81 and a motor shaft 82 . The motor housing 81 is fixedly connected with the grip bar 42 . The motor casing 81 is provided with the connection terminal 3 . The drive shaft 41 is connected to one end of the motor shaft 82 through a speed reducer 83 . The other end of the motor shaft 82 passes through the handle bar 42 .

[0043] see Figure 4 , The power switching mechanism 2 includes a switch 21 , a pressing rod 22 , a latch 23 and an insertion spring 24 . The switch 21 and the pressing rod 22 are located on both sides of the latch 23 . The switch 21 is fixed in the handle bar 42 . Switch 21 is a push switch, because the control motor 8 starts and stops. The pressing rod 22 passes through the grip rod 42 . The latch 23 is slidably connected in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com