Thermal transfer ribbon and thermal transfer ribbon recycling device

A technology for recycling devices and carbon ribbons, which is applied in the direction of inking devices, ink ribbons, printing, etc., can solve the problems of difficult recycling and reuse of carbon ribbons, pollute the environment, waste resources, etc., achieve better stripping effects, reduce environmental impact, The effect of improving the peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

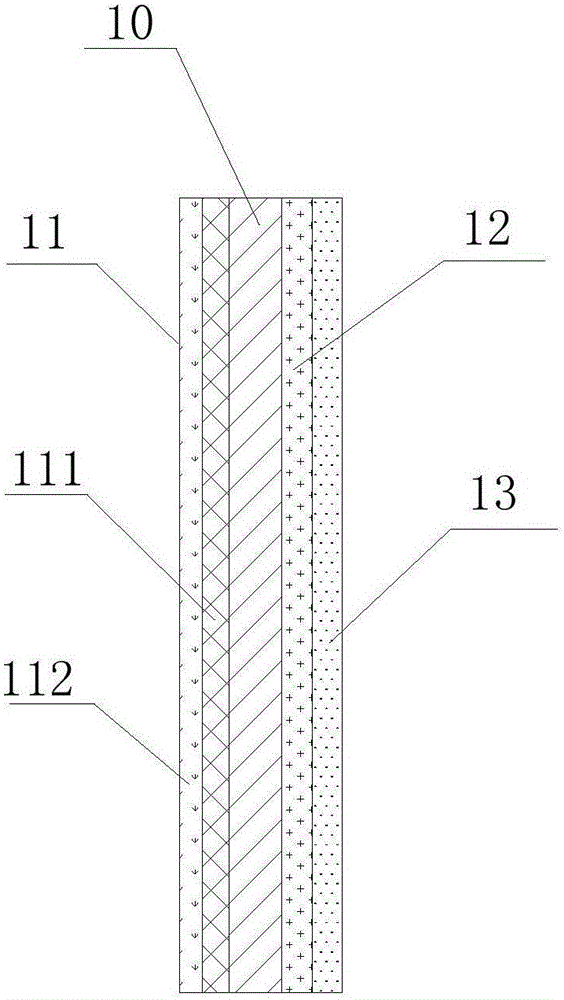

[0069] The carbon ribbon provided by the present invention includes a tape base 10, and the two surfaces of the tape base 10 are covered with an ink layer 13 and a back coat layer 11 respectively;

[0070] The ink layer 13 comprises the following weight ratio components:

[0071] 55% carbon powder, 20% resin, 15% paraffin, 8% silicone oil and 2% additives.

[0072] The auxiliary agent is a mixture of anti-offset agent, heat-resisting agent and slip agent, and the volume ratio of anti-offset agent, heat-resisting agent and slip agent is 0.8:0.8:0.6.

Embodiment 2

[0074] The carbon ribbon provided by the present invention includes a tape base 10, and the two surfaces of the tape base 10 are covered with an ink layer 13 and a back coat layer 11 respectively;

[0075] The ink layer 13 comprises the following weight ratio components:

[0076] 60% carbon powder, 18% resin, 10% paraffin, 10% silicone oil and 2% additives.

[0077] The auxiliary agent is a mixture of anti-offset agent, heat-resisting agent and slip agent, and the volume ratio of the anti-offset agent, heat-resisting agent and slip agent when mixed is: 0.8:0.8:0.7.

Embodiment 3

[0079] The carbon ribbon provided by the present invention includes a tape base 10, and the two surfaces of the tape base 10 are covered with an ink layer 13 and a back coat layer 11 respectively;

[0080] The ink layer 13 comprises the following weight ratio components:

[0081] 62% carbon powder, 17% resin, 13% paraffin, 7% silicone oil and 1% additives.

[0082] The auxiliary agent is a mixture of anti-offset agent, heat-resisting agent and slip agent, and the volume ratio of anti-offset agent, heat-resisting agent and slip agent is 0.9:0.9:0.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com