Connecting rod clamping mechanism

The technology of a clamping mechanism and a connecting rod mechanism, which is applied in the field of clamping mechanism equipment, can solve the problems of increasing production cost, low clamping efficiency, time-consuming and labor-intensive, etc., and achieves the effects of high space utilization, simple and flexible structure, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

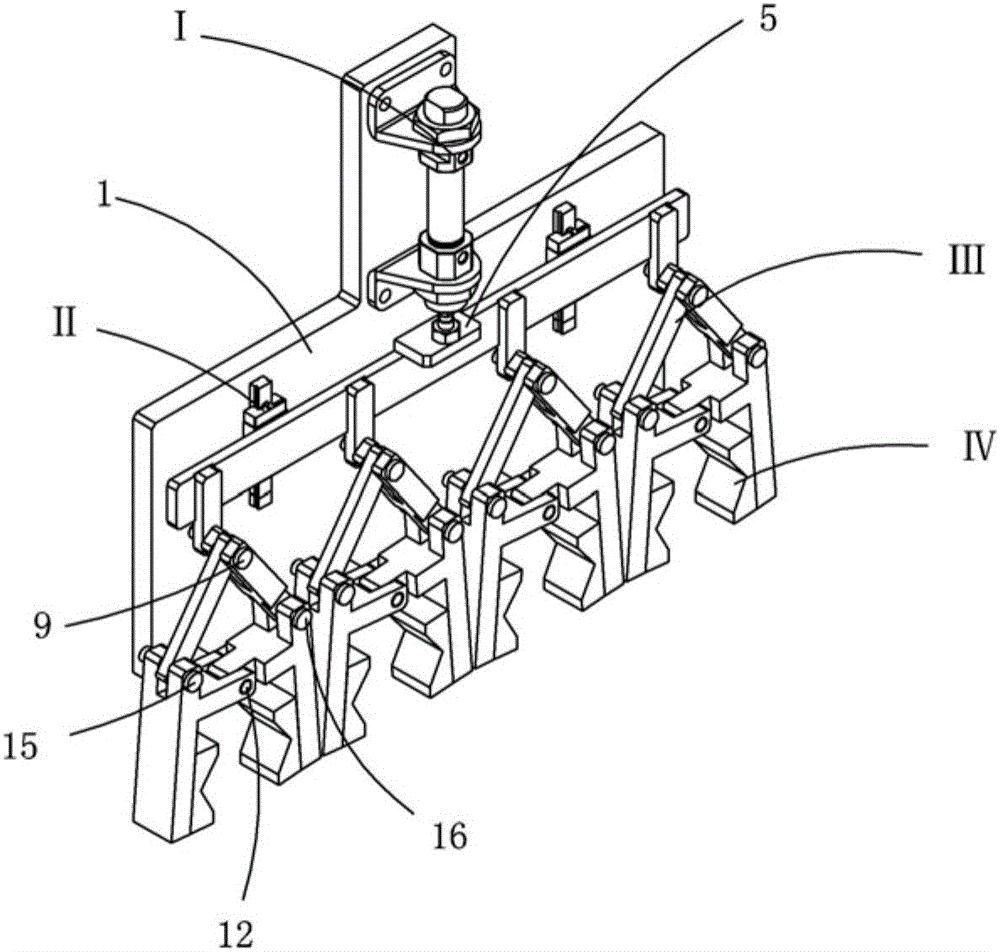

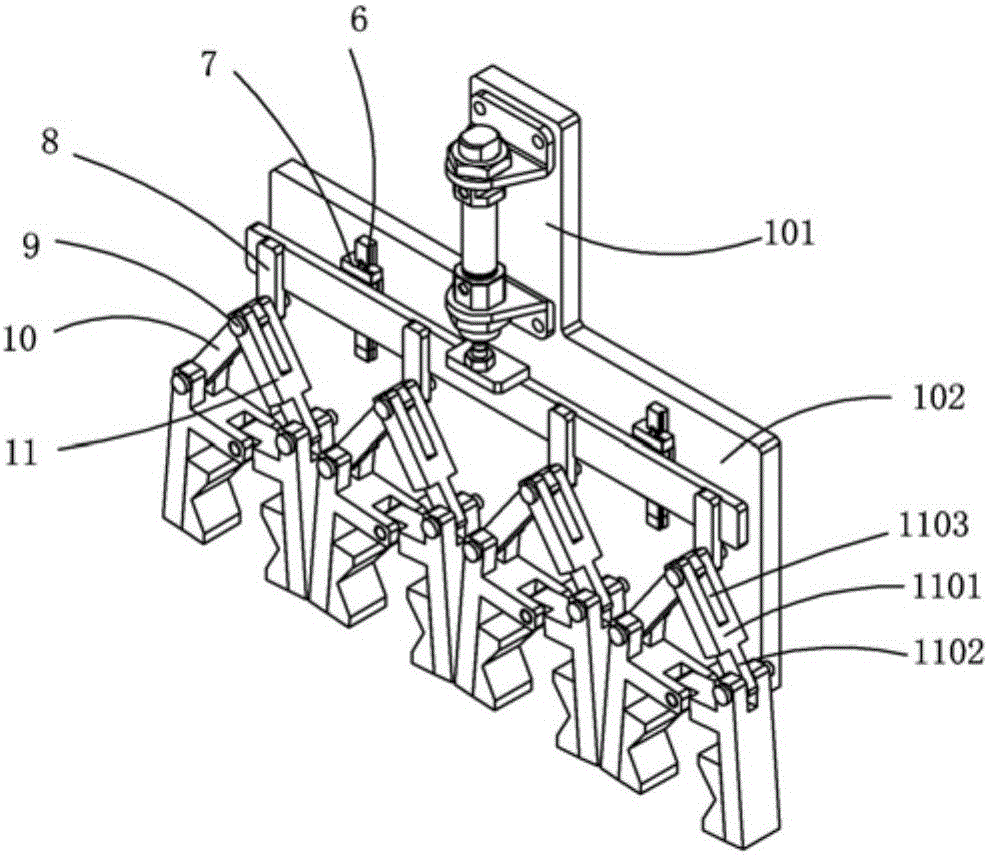

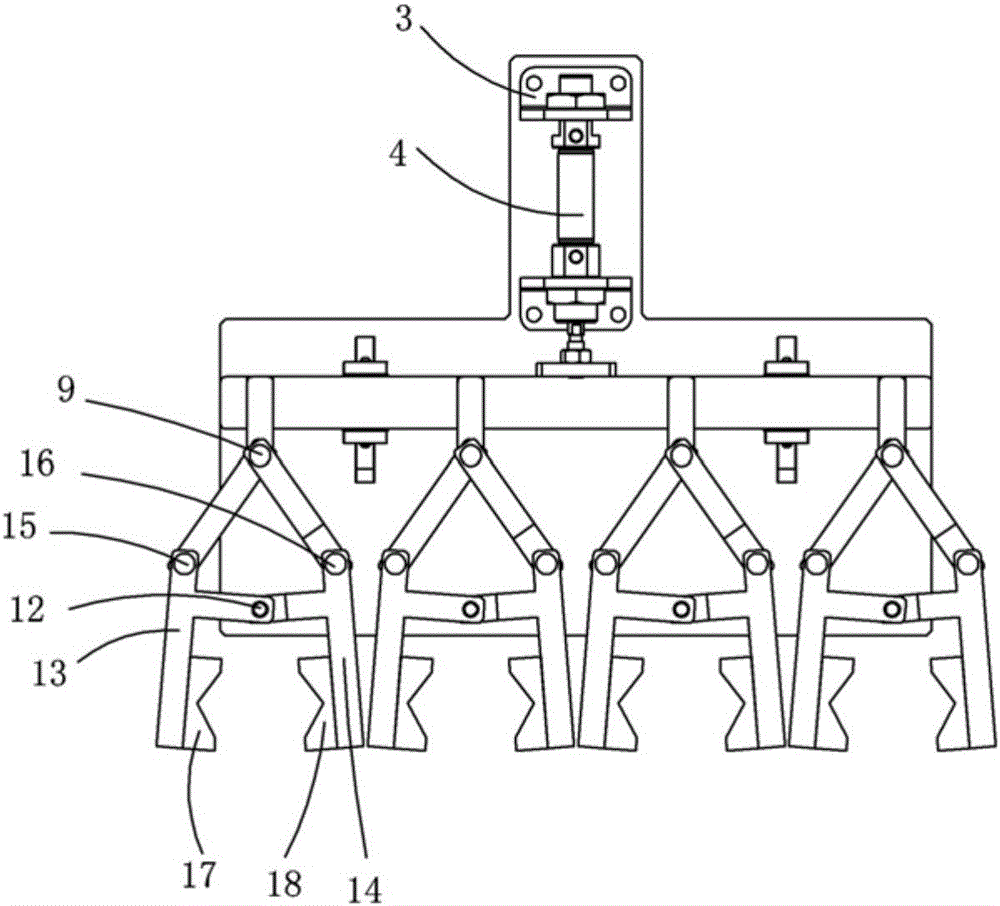

[0025] Examples, see attached Figure 1~6 , a connecting rod clamping mechanism, including a carrier plate 1 and a drive assembly I installed on the carrier plate, the lower end of the drive assembly is connected to a pull rod 2, and a guide assembly that guides the pull rod is installed on the carrier plate II; the lower end of the pull rod is connected with a linkage mechanism III, and the lower end of the linkage mechanism is equipped with a jaw assembly IV; the drive assembly drives the pull rod to move along the guide assembly, and under the action of the linkage mechanism, the clamp can be The jaw assembly clamps or loosens the product.

[0026] The carrier board is a convex structure, a driving assembly is installed on the small end 101 of the convex structure, and a guide assembly is installed on the large end 102 of the convex structure.

[0027] Four sets of linkage mechanisms are installed side by side at the lower ends of the pull rods, and a set of jaw assemblies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com