Freezing bottom-sealing construction method for deep foundation pit

A construction method and technology of deep foundation pits, which can be used in infrastructure engineering, excavation, construction, etc., can solve problems such as large buried depths, and achieve the effects of shortening the construction period, reducing construction difficulty and risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

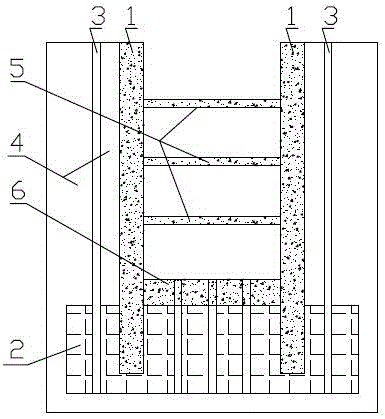

[0033] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples.

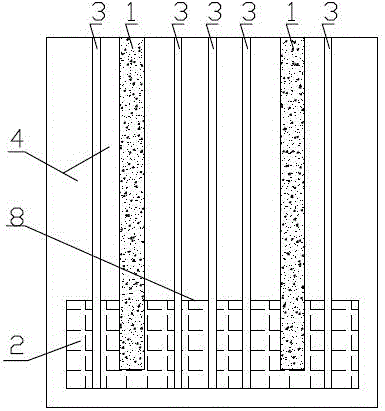

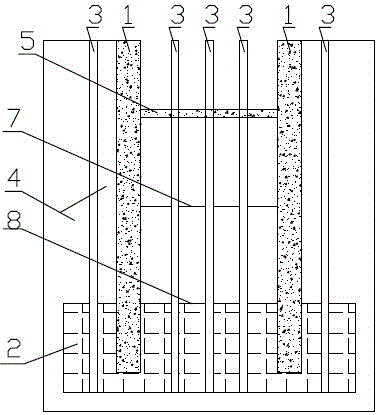

[0034] Referring to the accompanying drawings, the implementation method of deep foundation pit freezing bottom sealing excavation construction method includes the following steps:

[0035] Step 1: Construction of underground diaphragm wall 1. The underground diaphragm wall has the function of retaining soil and waterproofing. During construction, it is necessary to ensure that the verticality of the wall meets the requirements, and the joints between two adjacent walls must have a good water sealing effect; the underground diaphragm wall must be constructed to a specified depth. Embedded to a certain depth in the designed frozen soil body bottom plate 2, but the depth cannot exceed the bottom of 2.

[0036] Step 2: Freeze pipe 3 construction. During the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com