Sectional type vertical lift high-rise comb fork type parking equipment

A technology of parking equipment and vertical lifting, which is applied to the buildings, building types and buildings where cars are parked.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

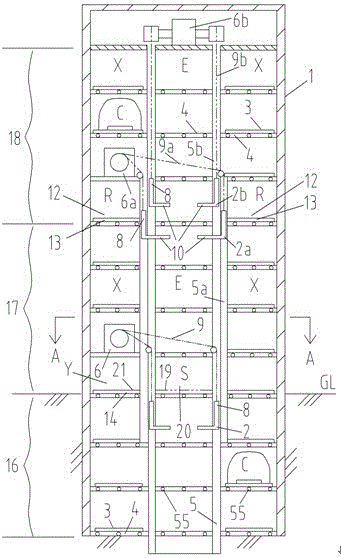

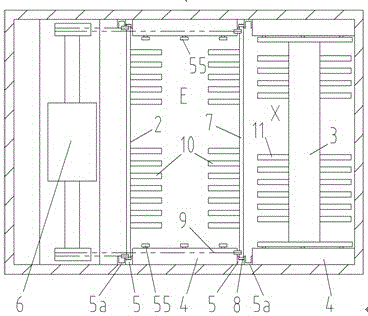

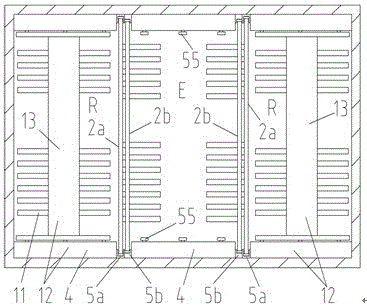

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] A segmented vertical lift high-rise comb-fork parking equipment is divided into an underground section 16, an above-ground section 17 and a high-rise section 18 in the lifting shaft E of the high-rise comb-fork parking equipment 1, and each section is set separately Guide rail and be equipped with the lifter and drive unit that band comb-toothed fork is respectively: carry out the first lifter 2 and the first lifter drive unit 6 that carry out between the first floor of underground section 16 and ground section 17 and carry out The first guide rail 5 that guides the first elevator 2; the second elevator 2a and the second elevator drive 6a that carry out between the first layer of the ground section 17 and the high-rise section 18, and the second elevator 2a that guides the second elevator 2a. Guide rail 5a; The third elevator 2b and the third elevator driving device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com