A warming, smoke dispersing and ventilation system for construction of underground workshops in alpine regions

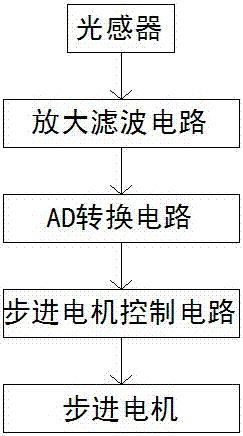

A technology for underground workshops and alpine areas, which is used in mine/tunnel ventilation, air heaters, lighting and heating equipment. Poor working environment and other problems, to achieve the effect of convenient and fast transportation and installation, good dust removal effect, and long distance for heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

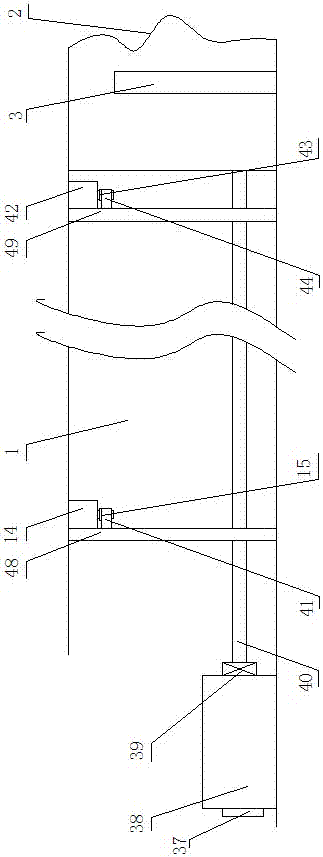

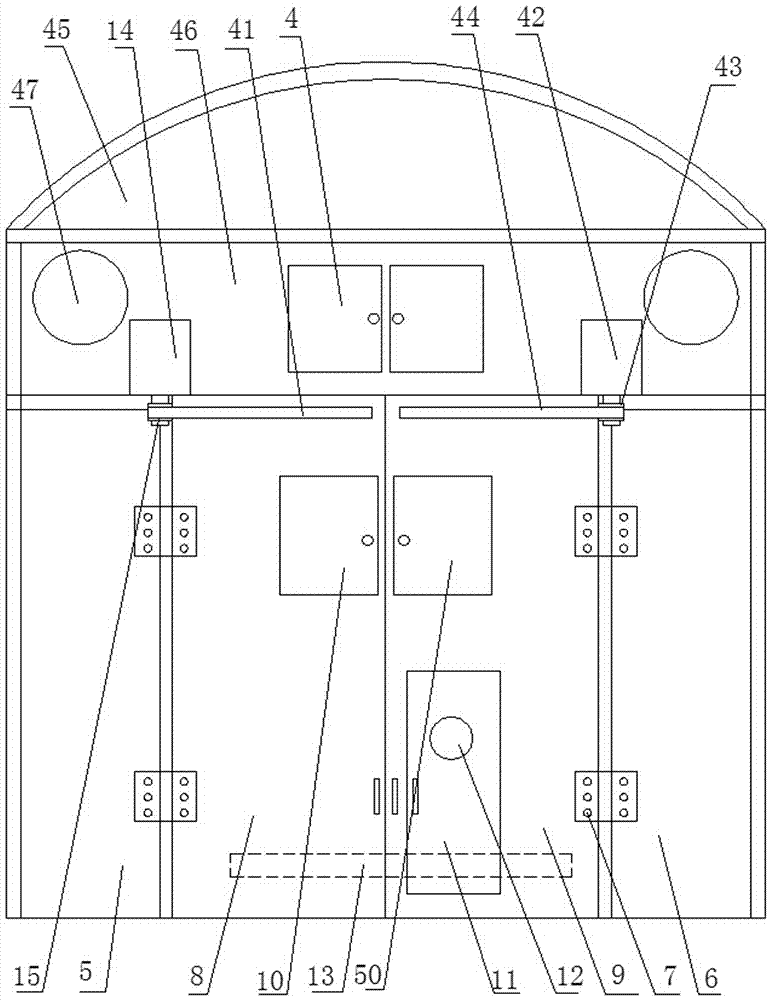

[0027] A warming, smoke-dispersing and ventilation system for an underground factory building in an alpine region. Its composition includes: a damper, a fan 39, a heat sender, and a dust collector 3. The damper includes a front damper 48 and a rear damper 49. The damper is set In the tunnel 1, the front damper 48 is arranged at the front end of the tunnel 1, a heat transmitter is arranged in front of the front damper 48, the tunnel surface 2 is behind the rear damper 49, and the rear damper 49 is The dust collector 3 is placed between 49 and the palm face 2, the front damper 48 and the rear damper 49 both include an upper arc baffle 45, and the lower bottom surface of the upper arc baffle 45 is fixedly connected to the upper frame baffle 46 , the left and right sides of the upper frame baffle 46 are respectively provided with fan through holes 47, and an adjustment window I4 is opened between the fan through holes 47, and the lower bottom surface of the upper frame baffle 46 is...

Embodiment 2

[0029] According to Embodiment 1, the construction of an underground factory building in an alpine region is warm, smoke-dispersing and ventilation system. The dust collector 3 includes a base, and the top of the base is connected to a box body 16, and one end of the box body 16 is opened There is an air inlet 17, and a filter plate I18 is arranged on the upper right side of the air inlet 17, and the filter plate I plays the role of guiding the falling of large particles of dust, and a set of filter plate II19 is arranged on the upper right side of the filter plate I18, The filter plate II plays the role of filtering the small particles of dust in the upper layer. The rotating shaft 20 is arranged in the middle of the filter plate II19, and the rotating shaft 20 is connected to the filter plate III51. The filter plate III plays the role of filtering general dust. The right side of the filter plate III51 and the filter plate II19 is provided with a filter plate IV21, and the rig...

Embodiment 3

[0031] The warming, smoke dissipation and ventilation system for construction of an underground workshop in an alpine region described in Example 2, the base includes a fixed screw 34, and the top of the fixed screw 34 is fixedly connected to the box 16, and the The bottom end of the fixed screw rod 34 is threadedly connected to the screw sleeve 35, and the bottom end of the screw sleeve 35 is placed on the ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com