Device arranged on press machine and used for forging wind power flange blank making and punching

A flanged and press technology, applied in the field of punching devices, can solve problems such as dangers in manual operation, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

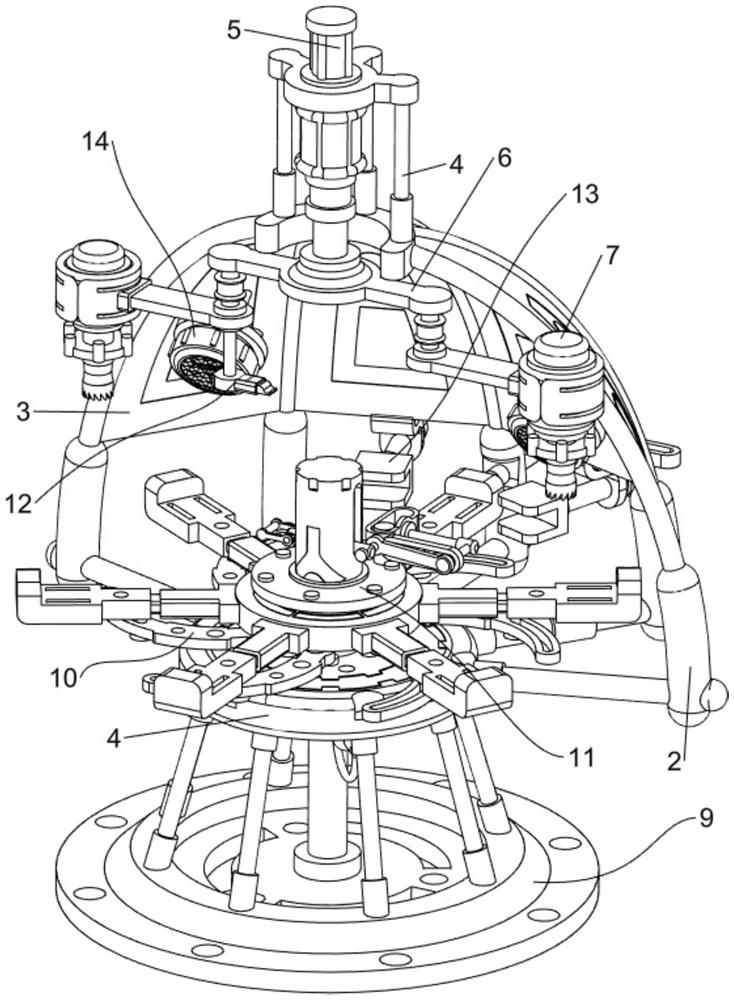

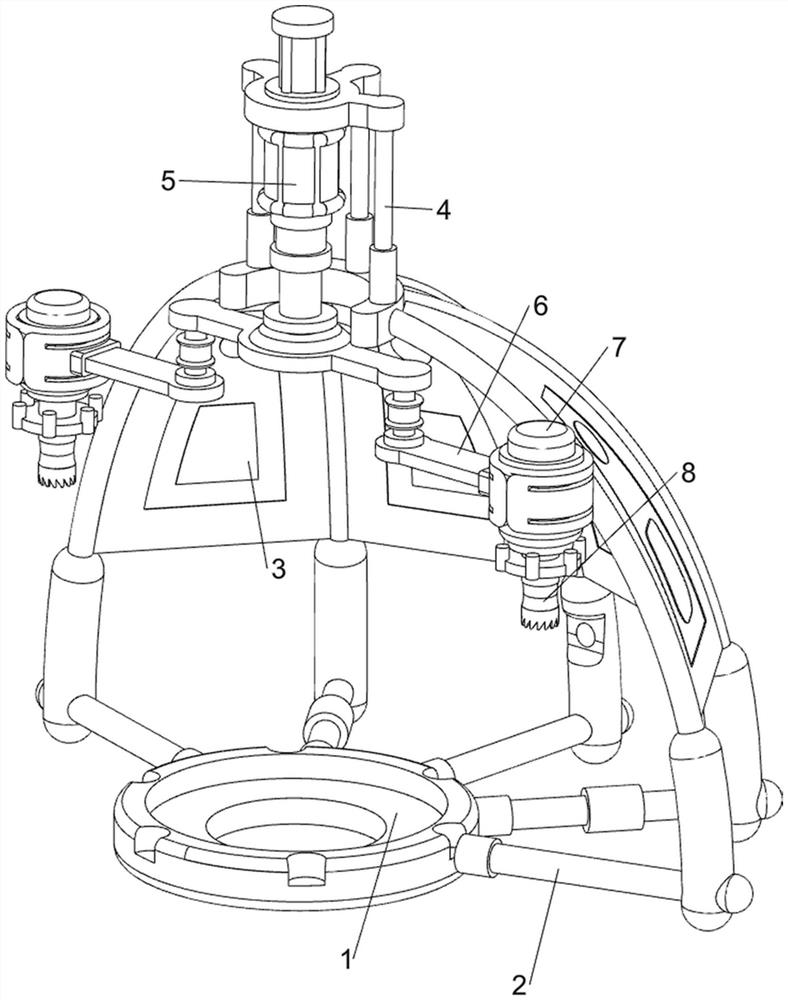

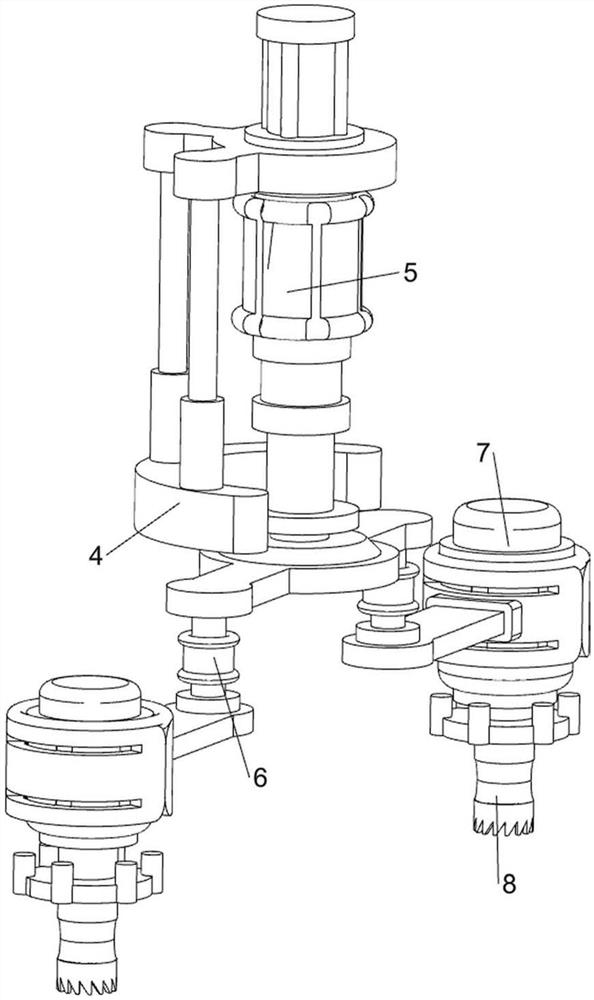

[0040] A device configured to forge wind power flange blank punching on a press, in Figure 1- Figure 3Shown in, including a support block 1, protective frame 2, protective plate 3, support frame 4, electric pushrod 5, lifting frame 6, servo motor 7, punching block 8, rotating mechanism 9, clamping mechanism 10, transmission mechanism 11 and dialing mechanism 12, support block 1 is provided with a protective frame 2 on the rear outer side, support block 1 is provided with a counterweight block at the bottom, which can increase the weight of support block 1, thereby reducing the possibility of dumping of the device, the protective frame 2 is evenly connected to four protective plates for blocking debris 3, The top of the protective frame 2 is connected to the support frame 4 by means of screw connection, the support frame 4 is connected to the top of the four guard plates 3, the support frame 4 is installed with an electric pushrod 5, the telescopic rod of the electric pusher 5 is ...

Embodiment 2

[0047] On the basis of Example 1, on Figure 1 、 Figure 14 and Figure 15 Shown in the middle, further comprising a loose release mechanism 13, the loose release mechanism 13 includes a second connecting block 130, a cotton block 131, a connection spring 132, a guide rod 133, a T-bar 134 and a push block 135, the middle two protective plates 3 are connected to the bottom of the second connection block 130, the two second connection block 130 are provided with a cotton block capable of limiting the flange 131, two cotton blocks 131 and the same side of the second connection block 130 rear are connected to the connection spring for reset 132, The lower middle sliding type of the protective frame 2 is provided with a guide rod 133, the slider 95 is in contact with the guide rod 133, the rear of the guide rod 133 is provided with a T-rod 134, the T-rod 134 is symmetrically provided with a push block 135, and the two push blocks 135 are connected to the back side sliding type of the cot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com