Pipeline connection auxiliary device for water conservancy construction

An auxiliary device and pipeline technology, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., which can solve the problems of easy water leakage, difficult operation, and inability to automatically clamp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

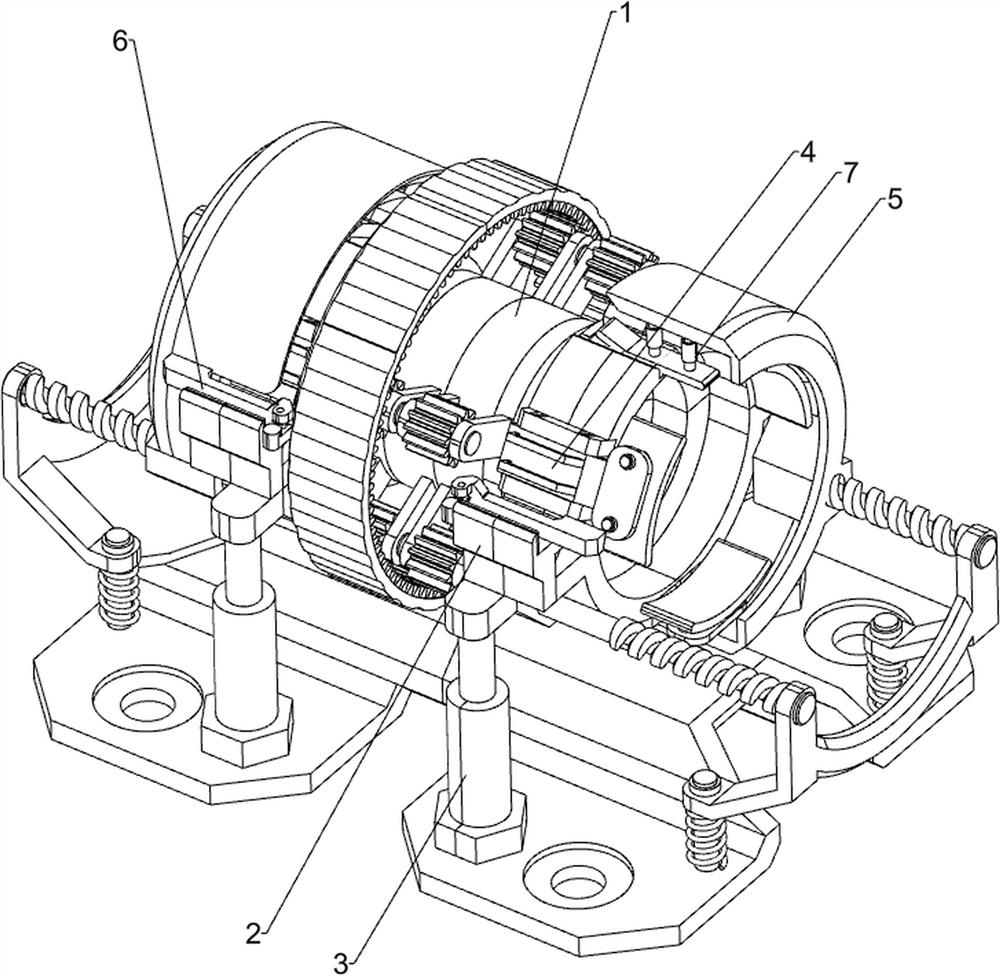

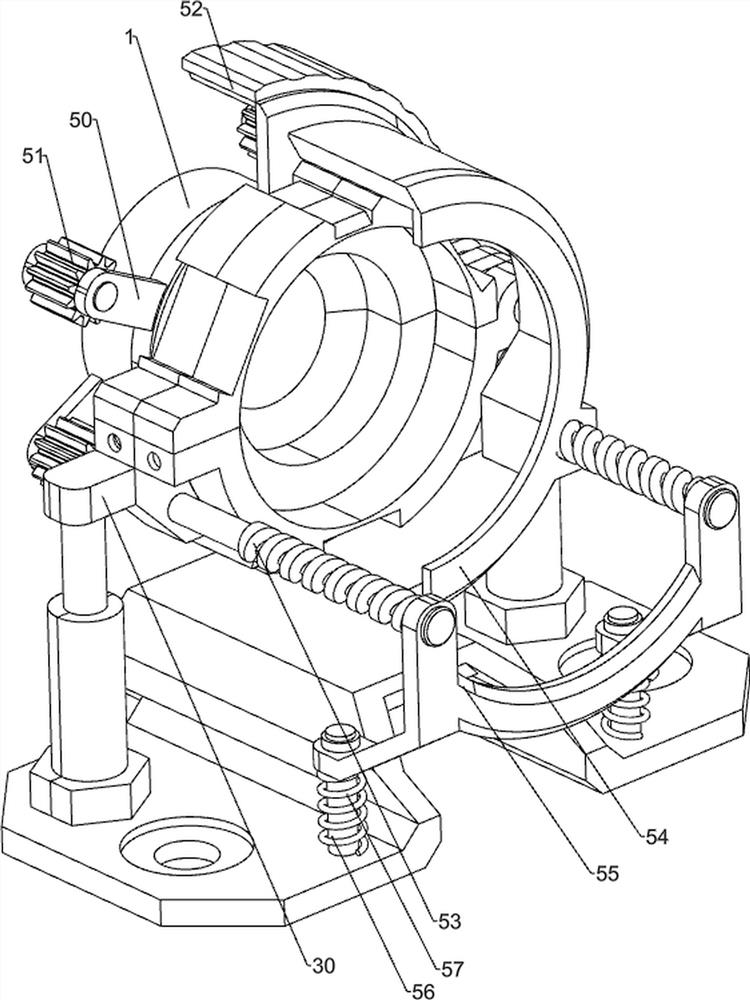

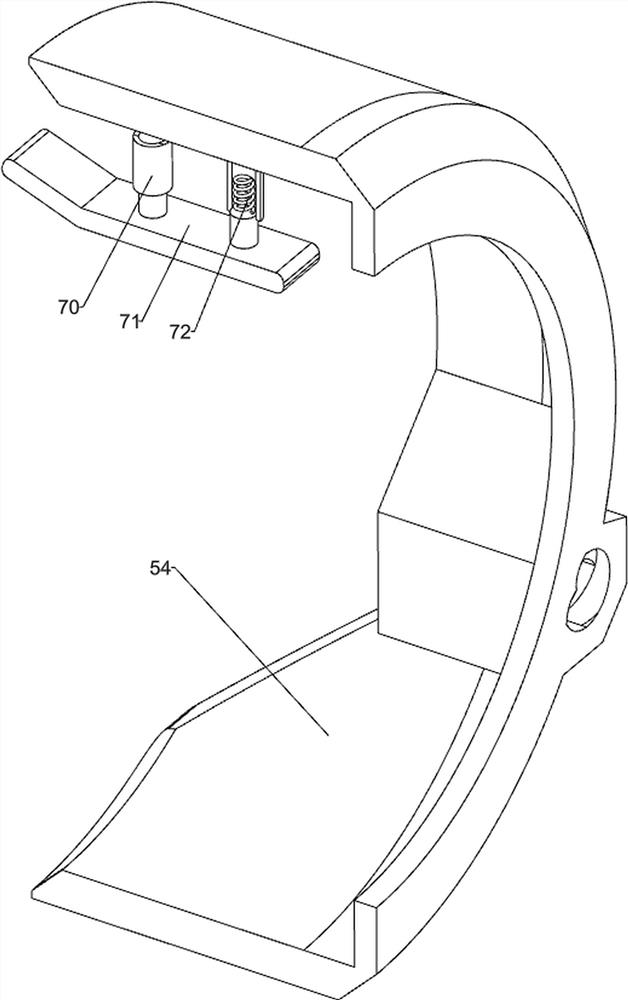

[0030] refer to Figure 1-Figure 8 A pipeline connection auxiliary device for water conservancy construction shown includes a connecting pipe 1, an opening and closing mechanism 2, a first support block 20, a first rotating rod 21, a rotating block 22, a torsion spring 23, a first guide rod 24, The first wedge block 25, the first spring 26, the placement mechanism 3, the second support block 30, the second guide rod 31, the first sliding sleeve 32, the mounting plate 33, the second spring 34, the clamping assembly 4, the third support Block 40, third guide rod 41, first slider 42, third spring 43, fourth guide rod 44, clamping block 45, fourth spring 46, sliding assembly 5, fourth support block 50, first gear 51 , the second gear 52, the screw rod 53, the second slider 54, the fifth support block 55, the fifth guide rod 56, the fifth spring 57, the unl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com