Cylindric pin with orientation correction for rough machining of lug

A cylindrical pin and lug technology, applied in the directions of shafts and bearings, mechanical equipment, pivots, etc., can solve the problems of time-consuming and laborious, the angle between the lugs and the lugs, and the increase in cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

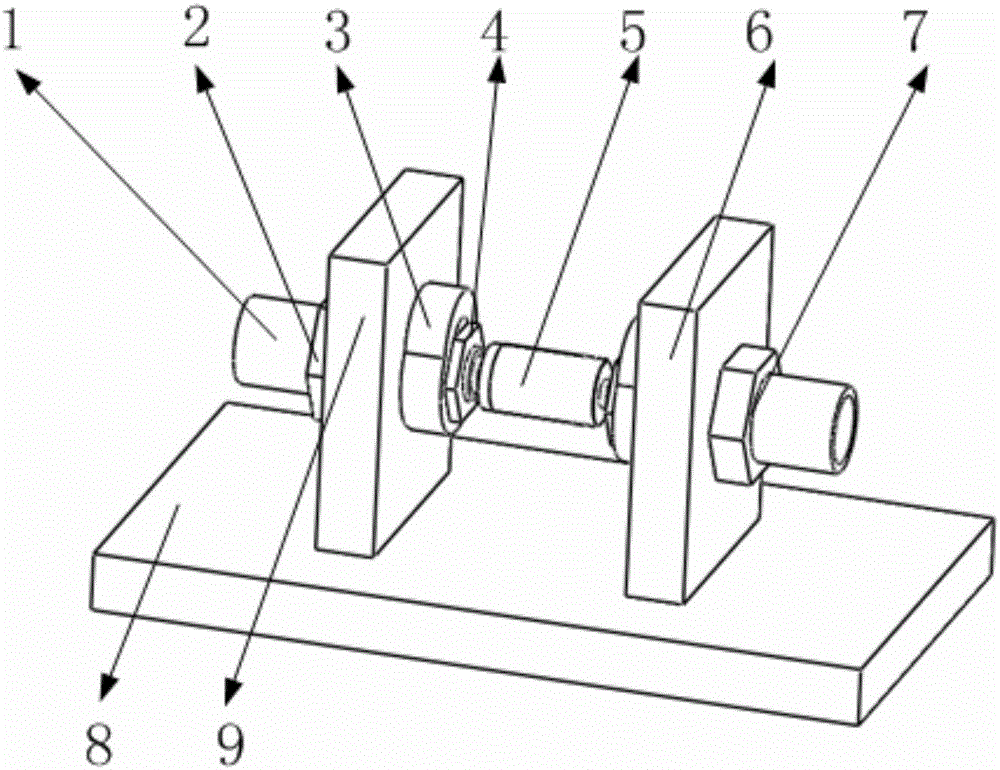

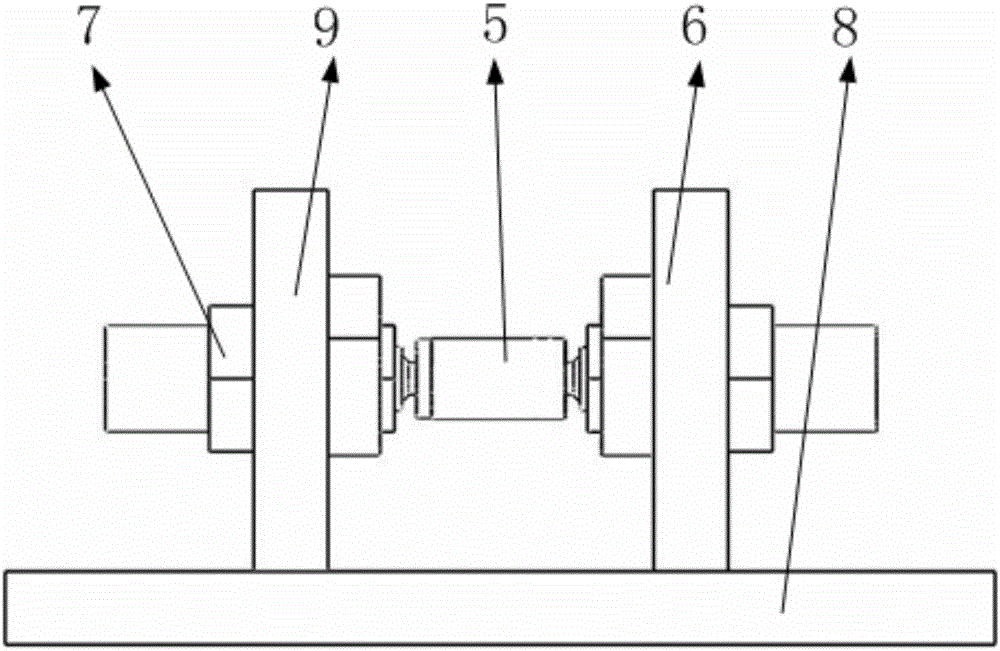

[0027] like figure 1 , 2 As shown, it includes cylindrical pin, first lug, lug support, second lug, and fixing mechanism, wherein the first lug and the second lug are installed side by side on the lug support, the first lug and the second lug Fixing mechanisms with exactly the same structure are installed on the lugs, and the cylindrical pin is installed between the two fixing mechanisms.

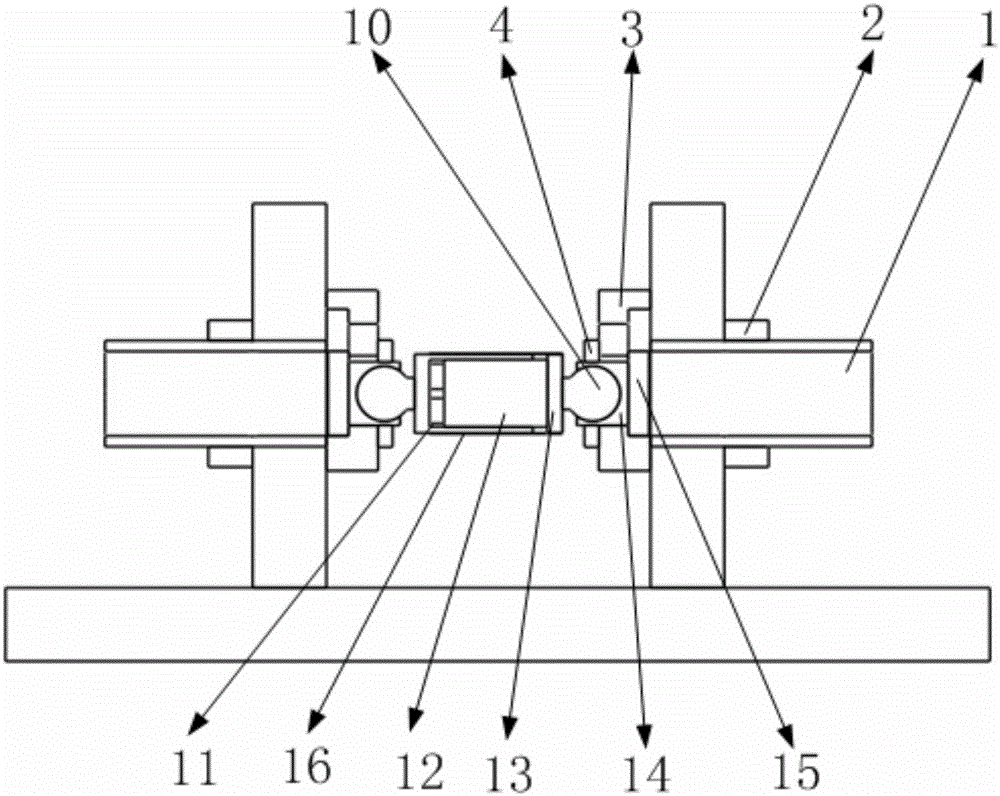

[0028] like image 3 As shown, the above-mentioned fixing mechanism includes a pillar, a first nut, an adjustment block, a second nut, a spherical shell, a spherical shell clamping plate, and a clamping plate supporting surface, wherein such as Figure 13 As shown, an adjustment block is installed at one end of the pillar, such as Figure 12 As shown, the adjustment block has a support surface on the side connected to the pillar, as shown in Figure 10 , 11 As shown, the spherical shell has a spherical inner cavity and the outer surface is a cylindrical surface with threads, and the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com